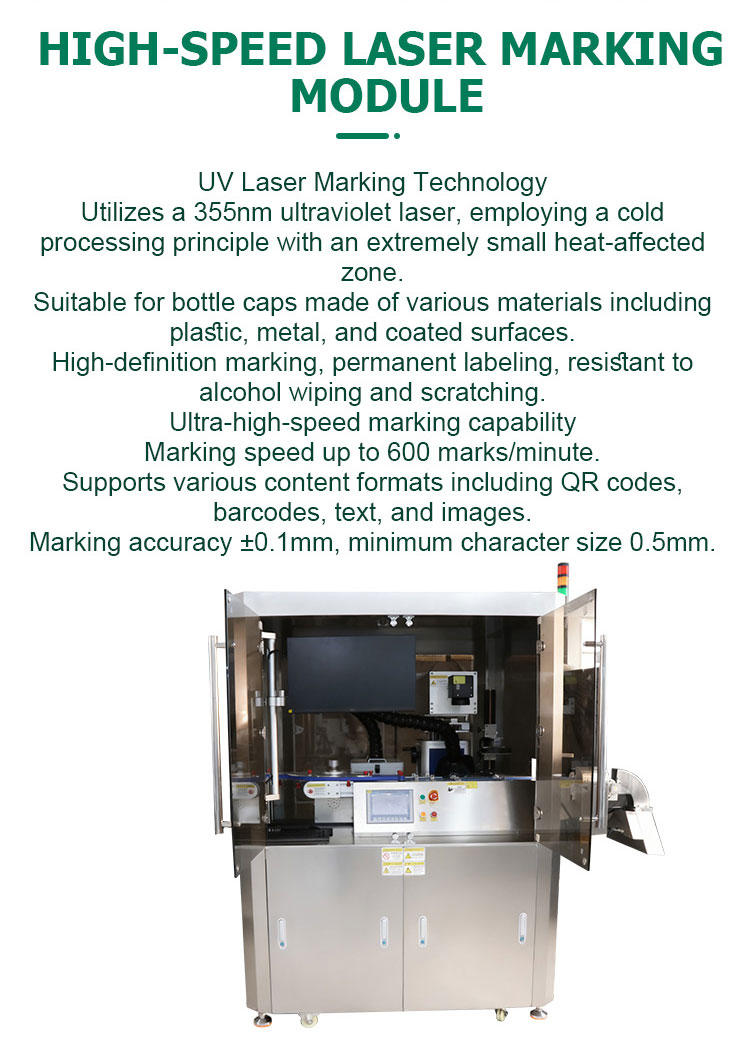

Integrated equipment for automatic feeding, coding, collection, and removal of bottle caps

Product number:

- Product description

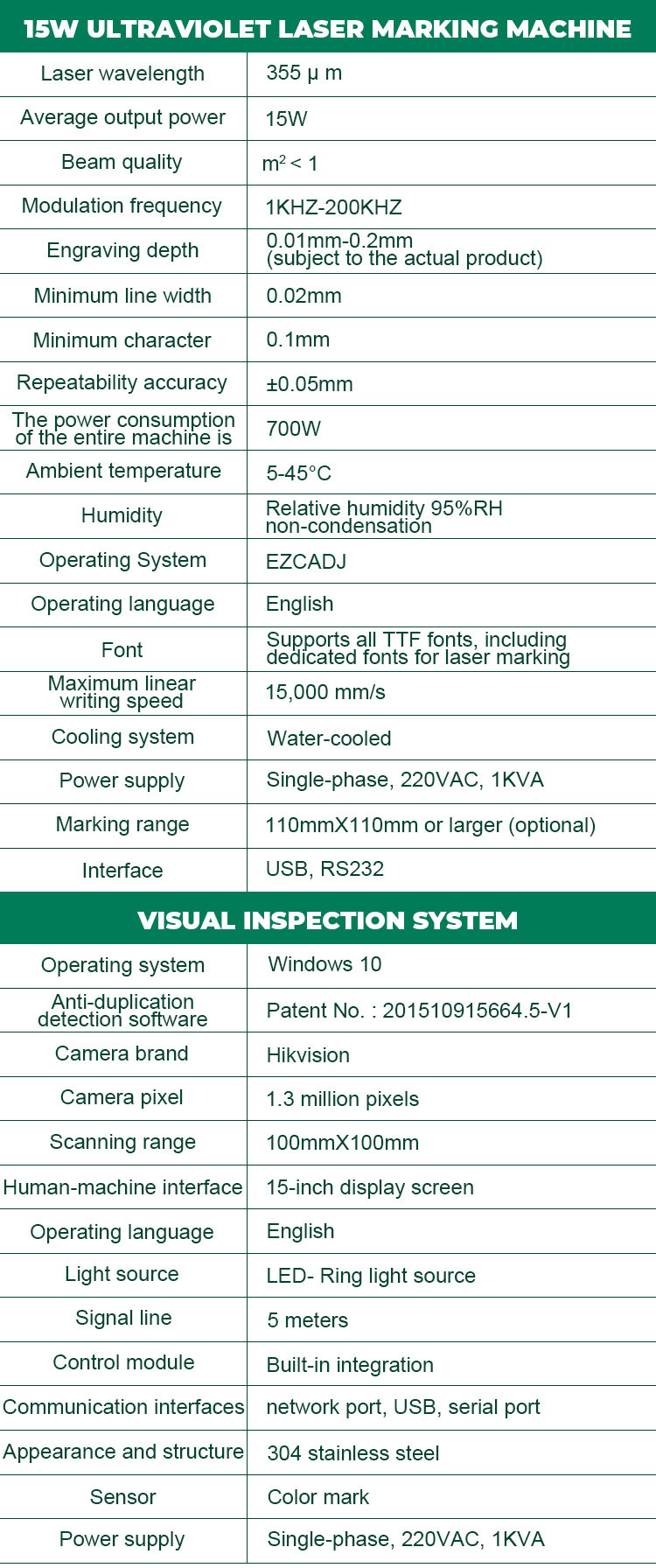

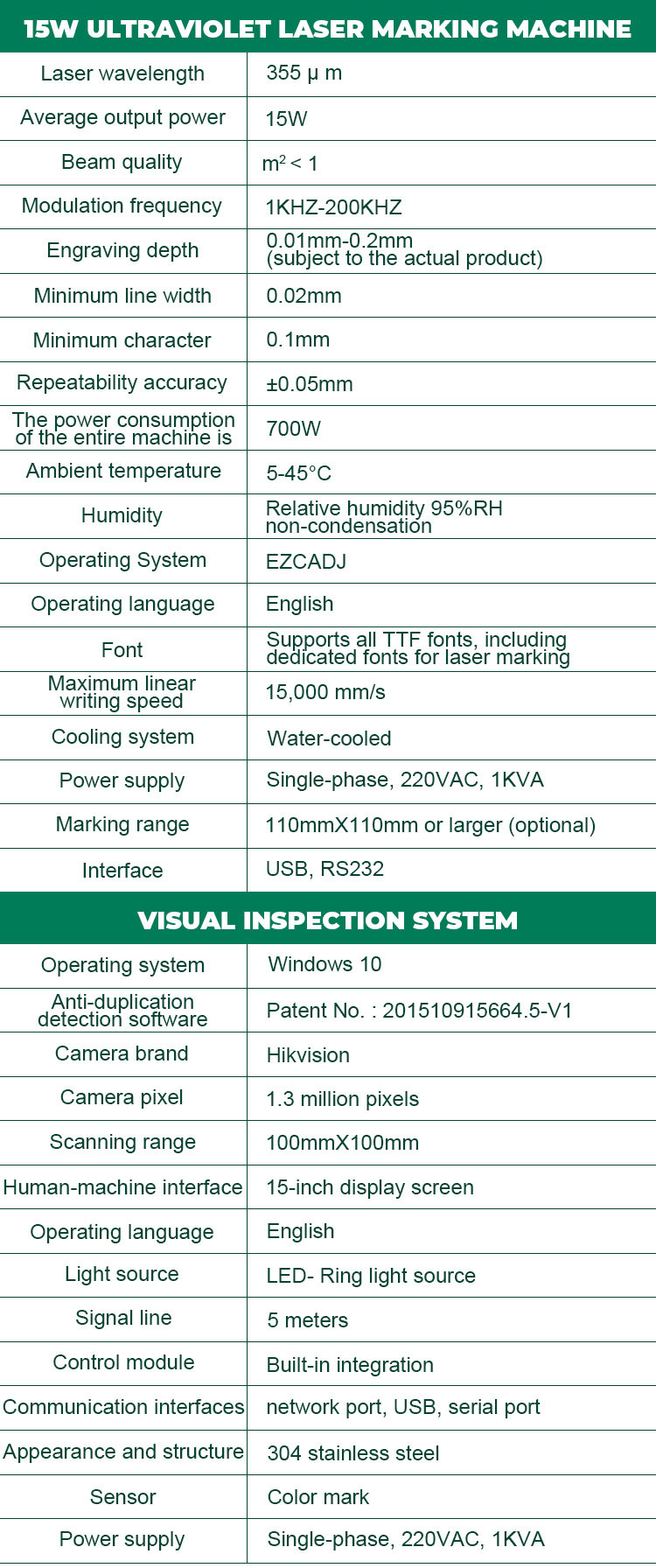

- Technical parameter

- Application field

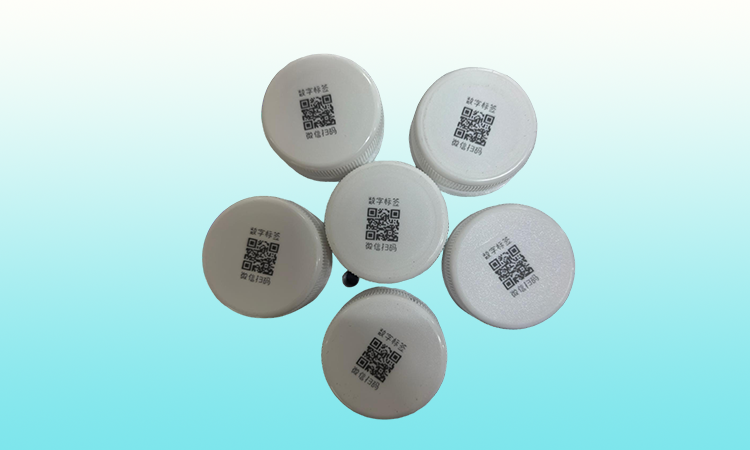

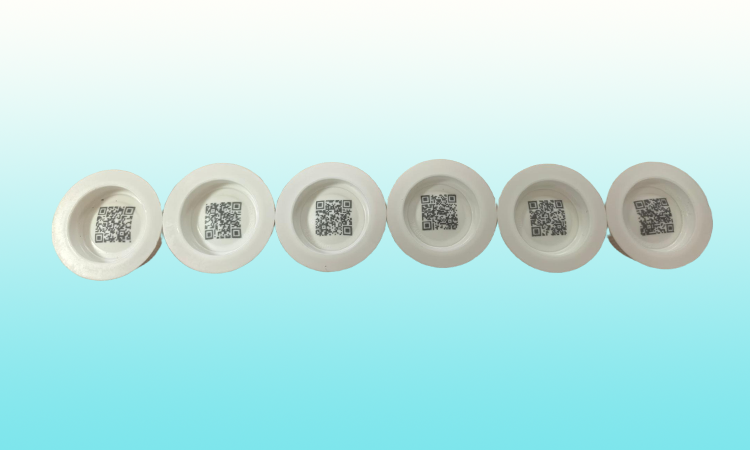

- Sample display

Alcohol and Beverage Industry

Application scenario: anti-counterfeiting and traceability of bottle caps for Baijiu, beer, red wine, high-grade mineral water and functional drinks.

Core value: To combat counterfeit and shoddy goods, achieve full chain anti smuggling management from production to end consumers, and protect brand value. The speed of 600 per minute perfectly matches the high-speed filling line.

Bottled water and beverage industry

Application scenario: Bottle cap traceability for high-end bottled water, tea drinks, juice and other products.

Core value: Establish an integrated entrance for consumers to scan codes to check their origin and participate in marketing activities, while meeting food grade safety coding requirements.

Seasoning and Food Industry

Application scenarios: High end soy sauce, edible oil, milk powder, health products, and other food packaging covers that require strict quality traceability.

Core values: Meet national food safety traceability requirements, establish consumer trust, and achieve precise management of production batches.

Pharmaceutical and Health Products Industry

Application scenario: Serial identification of drug bottle caps (especially OTC drugs) and health product bottle caps.

Core value: Meeting global and international drug traceability regulations (such as Chinese drug traceability codes and EU anti-counterfeiting directives), it is a necessary equipment for compliant production.

Cosmetics and personal care products industry

Application scenario: anti-counterfeiting of bottle caps/pump heads for skin care products, perfume and high-end cosmetics.

Core value: UV laser marking is beautiful and permanent, does not damage the packaging, and provides a platform for brand anti-counterfeiting and consumer interaction

ENQUIRYIntegrated equipment for automatic feeding, coding, collection, and removal of bottle caps

Chinese

Chinese English

English