- Product description

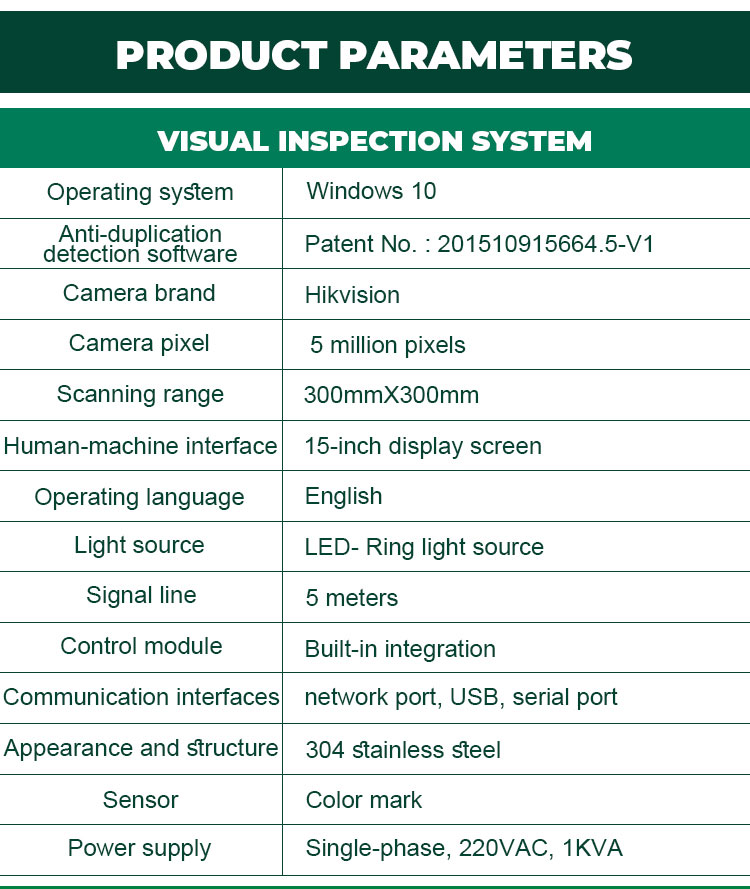

- Technical parameter

- Application field

- Sample display

1. Food and beverage industry

This is one of the most widely used fields, mainly focusing on the detection of key information such as production date, shelf life, batch number, etc.

Testing content: production date, shelf life, batch number, presence, clarity, and correctness of traceability source code.

Core values:

Eliminate missed or incorrect coding: prevent products without coding or with invalid coding from entering the market, avoid major customer complaints and food safety risks.

Ensure clear and readable information: Ensure that consumers and distributors can clearly see product information and comply with labeling regulations.

Accurate traceability: Accurate batch numbers are the cornerstone of product traceability.

2. Pharmaceutical and medical device industry

This is the field with the strictest requirements and the strongest mandatory regulations. The phrase 'quality comes from testing' is fully reflected here.

Testing content: drug expiration date, batch number, serial number, electronic supervision code (compliant with GMP/UDI regulations).

Core values:

Regulatory compliance: Meet the mandatory requirements of the National Medical Products Administration (NMPA) for electronic drug supervision codes and Unique Device Identification (UDI) for medical devices.

Patient safety: Ensuring 100% absolute accuracy of drug information is the guarantee of life safety.

Data integrity: providing accurate and reliable data sources for the entire supply chain.

3. Automotive and Parts Industry

Mainly used for component traceability and quality management, with extremely high requirements for industrial grade reliability.

Testing content: engine number, chassis number (VIN code), part number, production date, QR code, DPM code (direct component identification).

Core values:

Full lifecycle traceability: Any part can be traced back to the production line, production batch, or even raw materials through its identification, facilitating quality traceability and recall.

Prevent assembly errors: Read the part number on the assembly line to ensure that the installed part model is correct.

Supply chain management: facilitates the management of parts in warehouses and supply chains.

4. Electronics and Semiconductor Industry

The product is small and precise, with extremely high requirements for detection accuracy and speed.

Testing content: laser engraving on chip surface, silk screen characters on PCB board, electronic component number, production batch.

Core values:

Component traceability: Precisely track the production process of each chip and component for quality analysis (such as yield statistics).

Anti counterfeiting and quality control: Identify counterfeit components to ensure product quality.

Process control: In SMT and other processes, the correct processing program is called by recognizing the barcode/character on the board.

5. Daily chemical and cosmetics industry

Similar to the food industry, it focuses on brand image and consumer safety.

Testing content: production batch number, expiration date, ingredient description, anti-counterfeiting code.

Core values:

Maintain brand image: Avoid issues such as unclear date printing and missed printing that may affect brand reputation.

Protecting consumer rights: ensuring the accuracy and correctness of product information.

6. Printing and Packaging Industry

Used for testing the quality of one's own products.

Test content: Check whether the text on the printed material is accurate, whether there are omissions, errors, blurriness, dirt, etc.

ENQUIRYCharacter detection equipment

Chinese

Chinese English

English