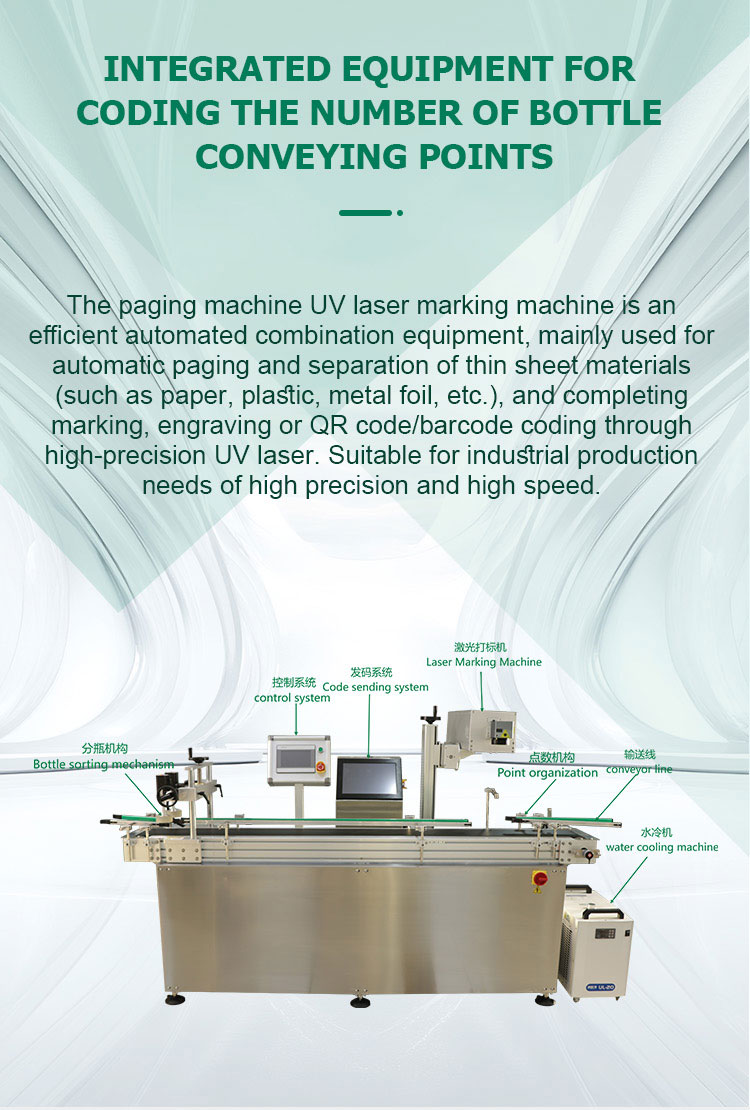

Integrated equipment for bottle coding and point counting

Product number:

- Product description

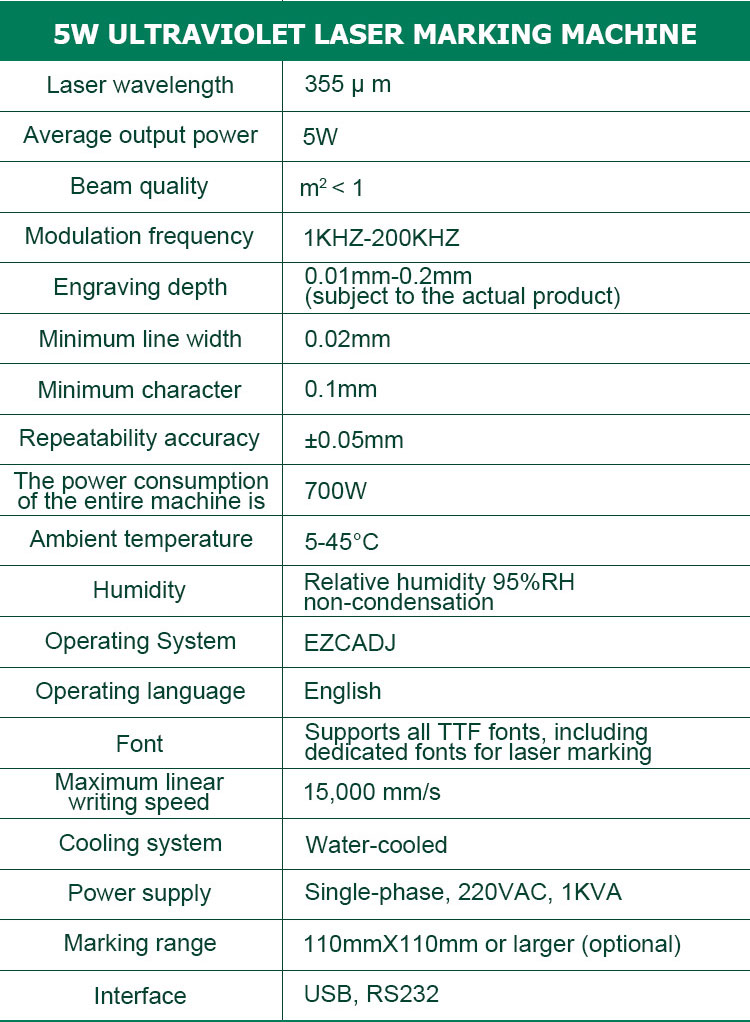

- Technical parameter

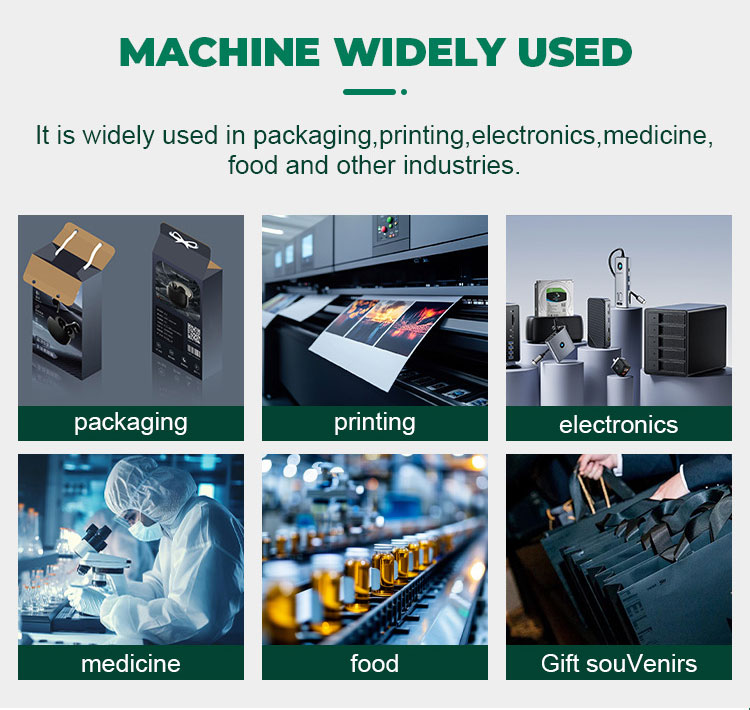

- Application field

- Sample display

1. Pharmaceutical industry (core applications)

This is the field with the strictest and most urgent requirements for traceability. The National Medical Products Administration (NMPA) has mandatory requirements for drug traceability.

Application Scenario:

Penicillin bottles and oral liquid bottles: Label the bottle body or bottom with a unique serial number (SN), batch number, expiration date, and electronic drug supervision code. UV laser can make extremely clear and wear-resistant marks on glass or medicinal plastics, facilitating subsequent scanning, correlation, and traceability.

Vaccine bottle: It requires extremely high clarity and permanence in tracing the source code, and UV laser coding is the best choice.

Eye drops and spray bottles: code the plastic bottles.

Core value: Meet GMP (Good Manufacturing Practice) and drug traceability regulations, achieve "one item, one code", ensure the full chain traceability of drugs from production to consumption, accurately recall, and combat counterfeit drugs.

2. Cosmetics and skincare industry

High end brands attach great importance to product appearance, anti-counterfeiting, and traceability.

Application Scenario:

Essence, perfume and toner bottles: mark the production batch number, expiration date and traceability code on the bottom of the glass or plastic bottle. The UV laser coding effect is exquisite and does not affect the beauty and design of the bottle body.

Anti counterfeiting and anti smuggling: Each bottle of product is assigned a unique identification code, allowing consumers to verify its authenticity and businesses to monitor channel flow.

Core values: brand protection, enhancing product quality, achieving precise marketing and channel management.

3. Food and beverage industry (high-end applications)

Mainly used for high-end beverages and small-sized foods with high quality traceability requirements.

Application Scenario:

High end beverage bottles and glass bottles of milk: indicate production date, shelf life, and batch number.

Seasoning bottles (such as small soy sauce and vinegar bottles): code and associate with traceability.

Health food oral liquid: Similar to drug requirements, precise coding and traceability are required.

Core values: food safety traceability, enhancing brand image, and meeting the quality requirements of high-end markets.

4. Chemical industry (daily chemical and fine chemical)

Application Scenario:

High end detergent and disinfectant bottles.

Small chemical reagent bottles: Clear labeling is required to distinguish different components and batches and avoid confusion.

Core values: Batch management, product identification, and prevention of misuse.

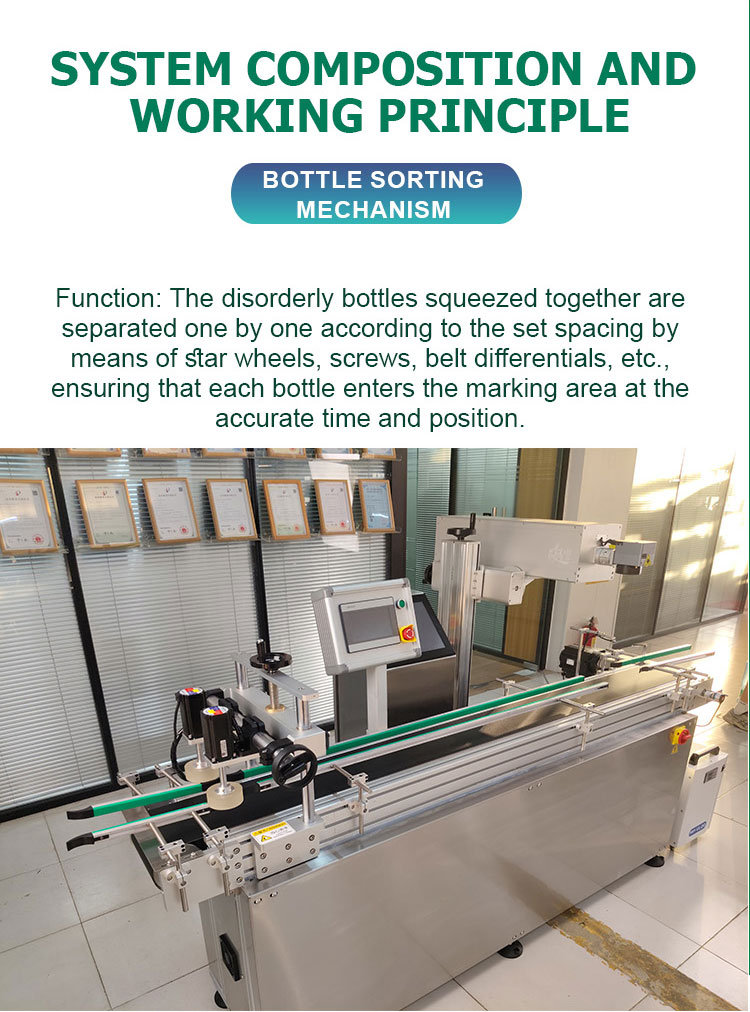

Equipment workflow and advantages

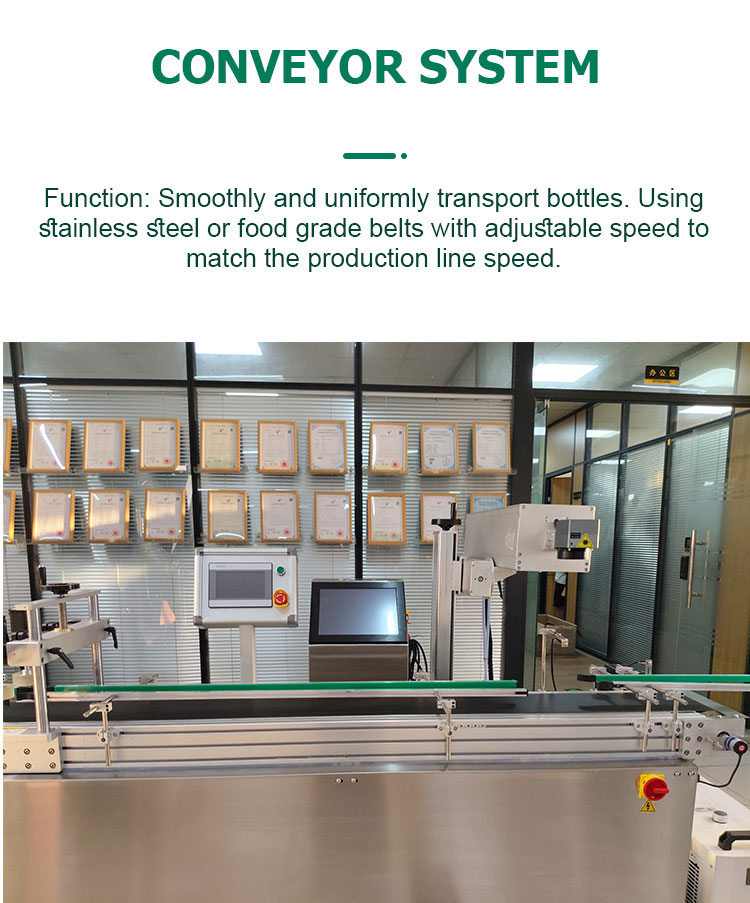

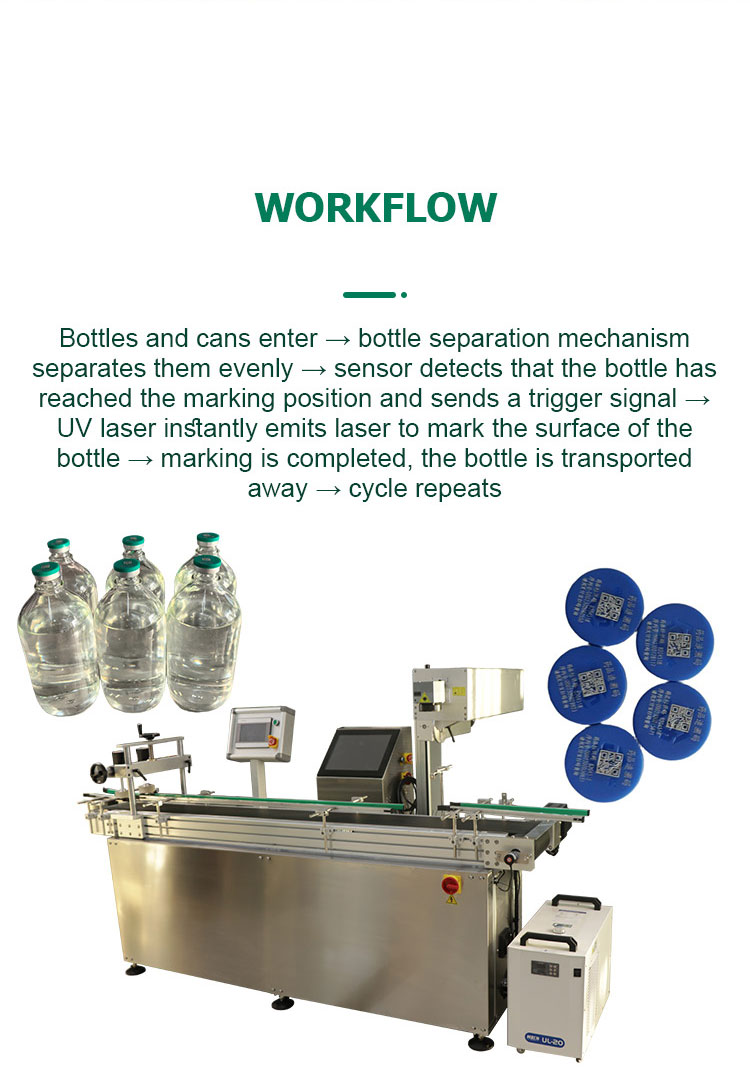

Bottle sorting: By using star wheels, screws, or belts to divide the bottles into equal parts, the messy or dense bottles are sorted in an orderly manner and sent one by one into the transmission track.

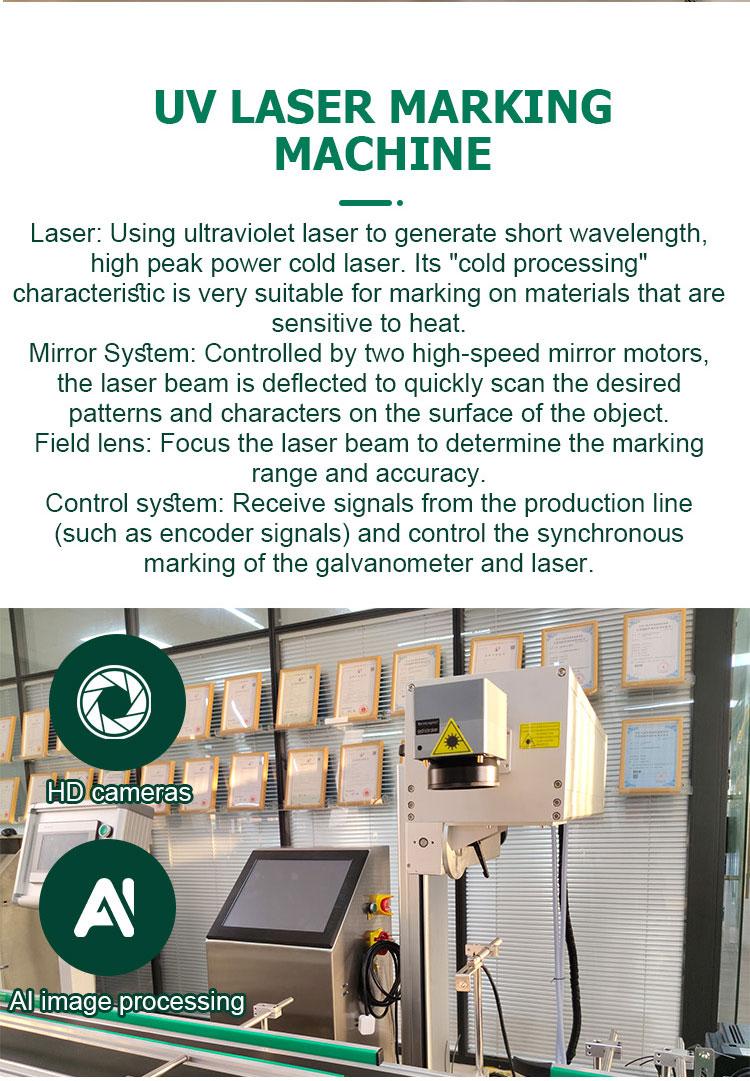

Marking: When the bottle reaches the laser marking station, the sensor triggers the UV laser to instantly engrave information (date, batch number, QR code, etc.) on the set position of the bottle body.

Points: At the exit, the bottles that have been successfully coded and passed are counted using photoelectric sensors or visual systems. The data can be uploaded to the MES/ERP system for production statistics, work order settlement, and other purposes.

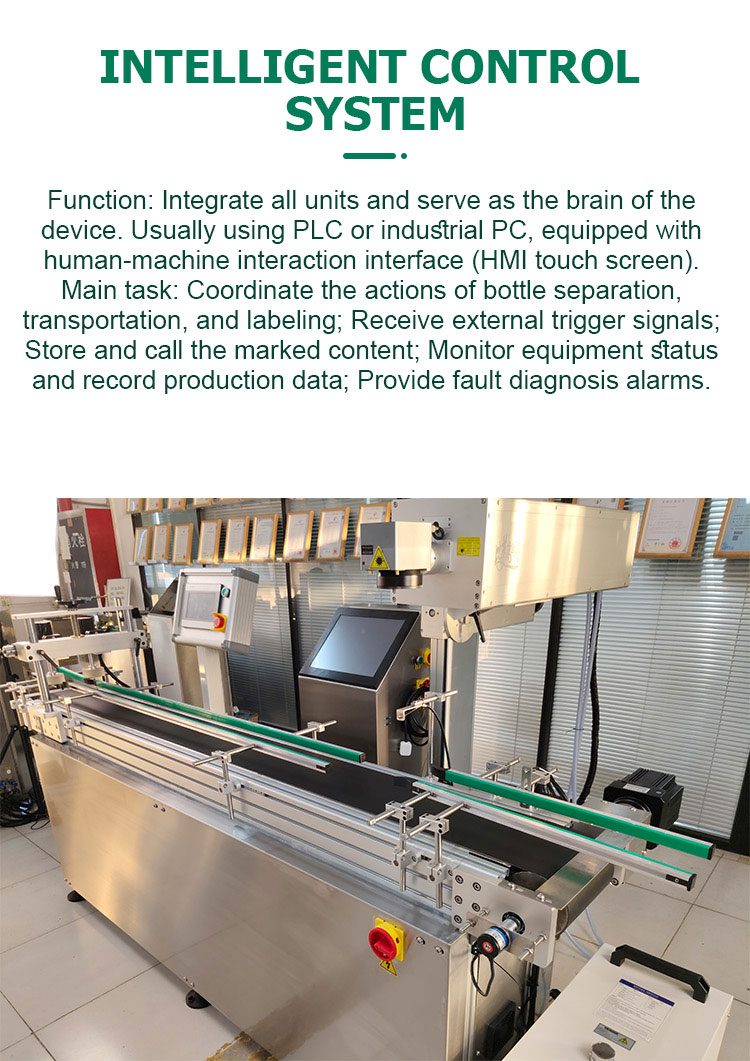

Integrated control: The entire process is uniformly scheduled by PLC (Programmable Logic Controller), efficiently coordinated, and does not require manual intervention.

ENQUIRYIntegrated equipment for bottle coding and point counting

Chinese

Chinese English

English