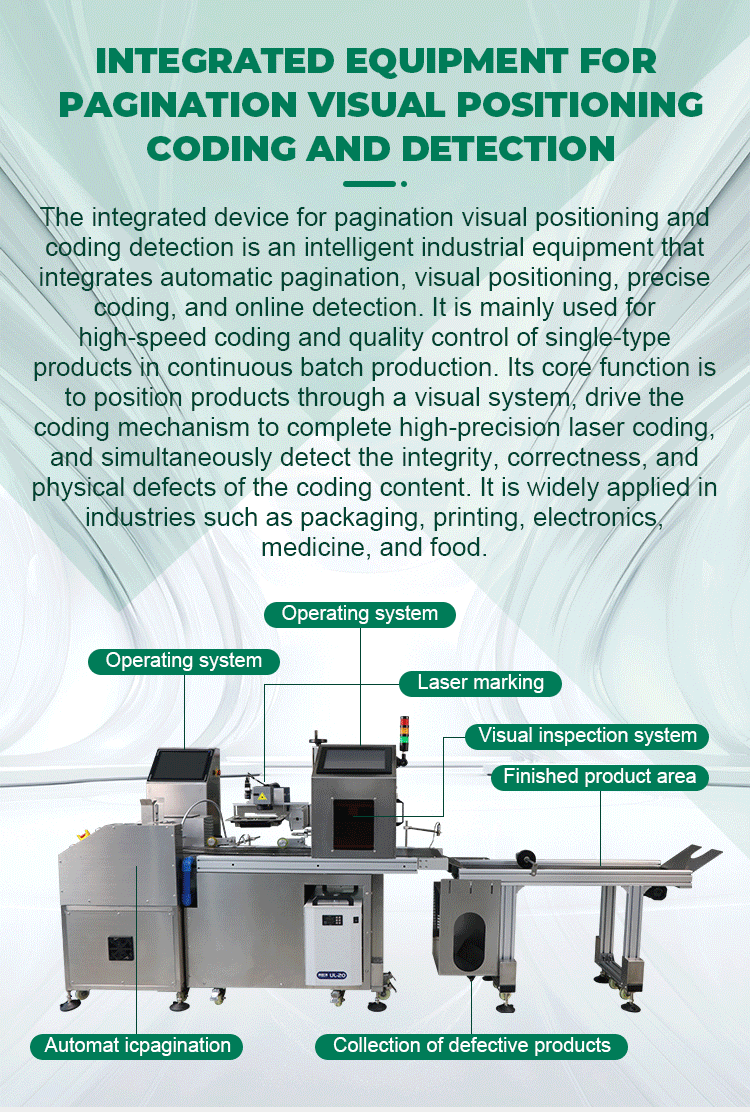

Integrated device for pagination visual positioning, coding and detection

Product number:

- Product description

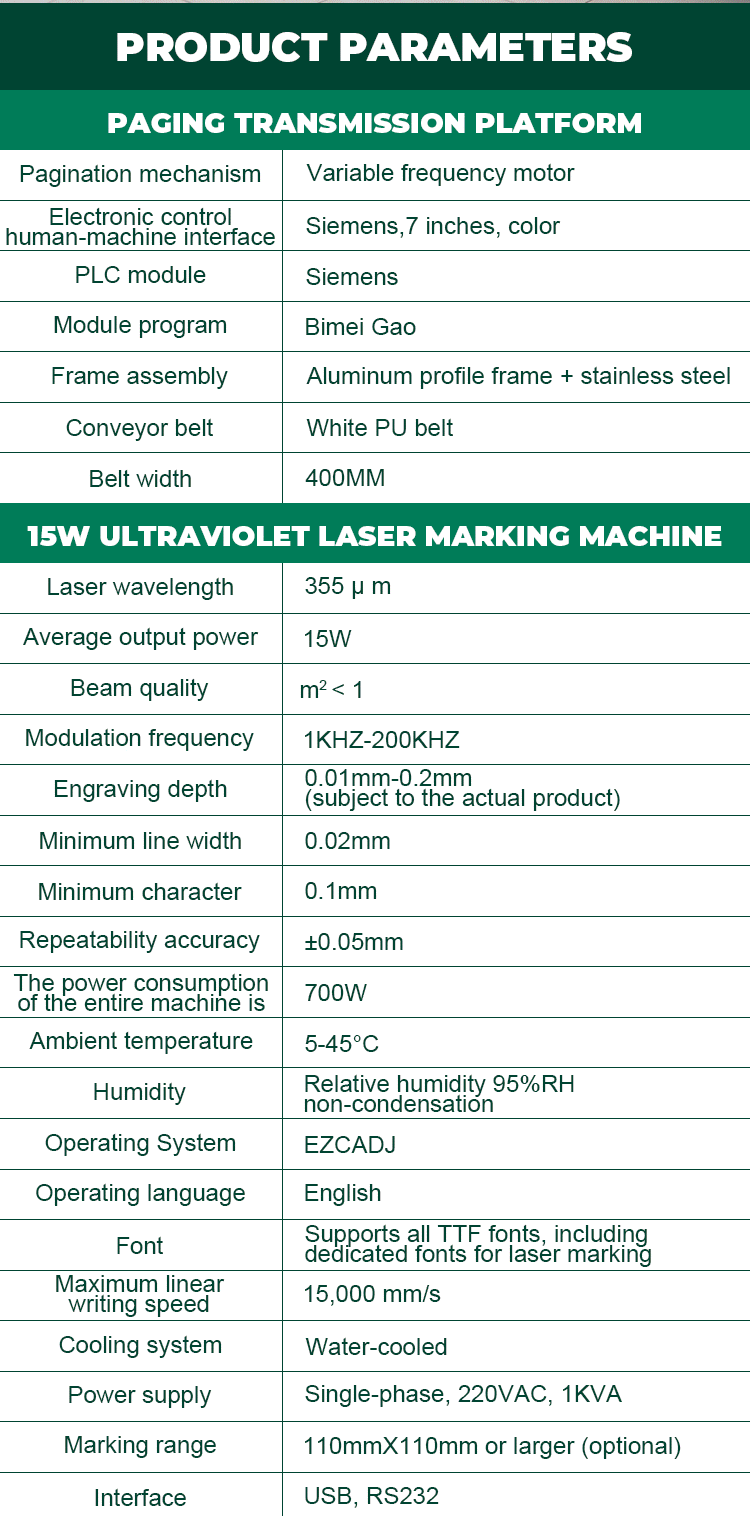

- Technical parameter

- Application field

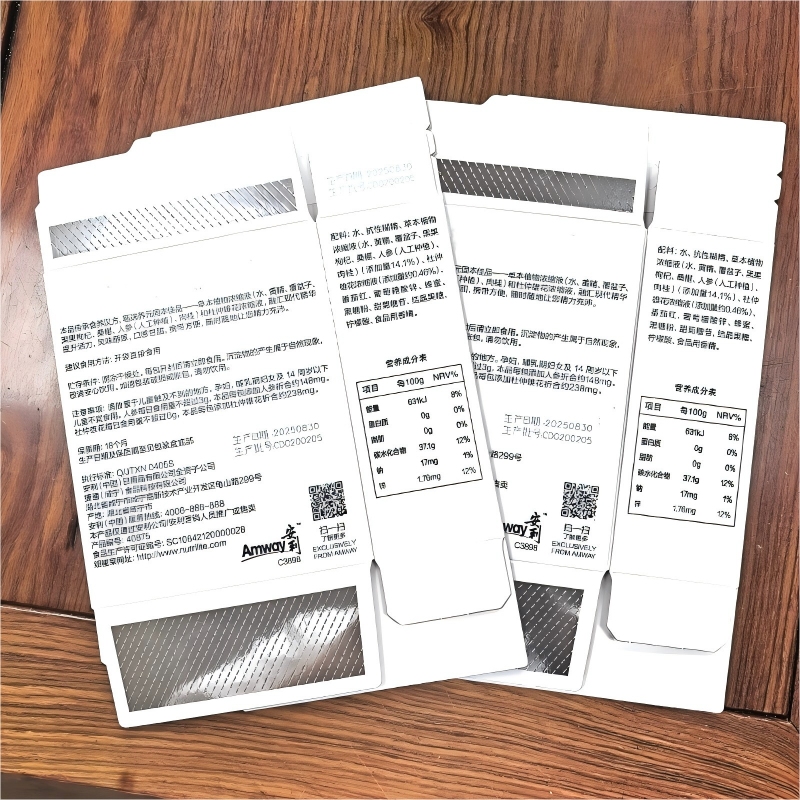

- Sample display

Printing and Packaging Industry (Core Applications)

This is the most classic application scenario of the device, used for personalized coding and quality inspection of printed products.

Specific application:

Drug instructions: Laser print unique traceability QR codes, drug batches, and other information on each drug instruction manual, and associate them with the medication box.

Electronic product manual: print model number, serial number, and production date.

Certificate of conformity/hang tag: Mark the date, inspection employee number, and anti-counterfeiting code on the certificate of conformity for clothing, toys, and other products.

Cards/flyers: Add variable data (such as unique codes and personalized information) to postcards, coupons, and brochures.

Core values:

Implement one item, one code: personalize the pages that were originally printed in bulk, endowing them with traceability and marketing functions.

100% quality inspection: Ensure that each coding content is correct, the position is accurate, clear and readable, and prevent the outflow of defective products.

Improve efficiency: Fully automated pagination, coding, and detection, with speeds far exceeding manual pasting or post coding.

2. Card and ticketing anti-counterfeiting industry

The industry has extremely high requirements for security, uniqueness, and accuracy.

Specific application:

Certificates/credentials: Numbering and verification of graduation certificates, honor certificates, and work permits.

Ticket/Coupon: Unique QR code, serial number, and seat number on movie tickets, scenic spot tickets, and concert tickets.

Anti counterfeiting label: paginate and code the adhesive label, and then paste it onto the product.

Core values:

High precision positioning: Ensure that the code is printed in the predetermined precise position and maintain the appearance of the ticket.

Anti counterfeiting and anti collusion: Each code is unique and is the core means of anti-counterfeiting.

Data association: The seat information in the ticketing system is accurately bound to the code on the physical ticket.

3. Food and Drug Industry (Secondary Packaging Materials)

Mainly used for identifying the packaging materials inside the product.

Specific application:

Pharmaceutical aluminum foil board: Page the PTP aluminum foil board (blister board for packaging tablets), print the drug batch number and expiration date.

Food packaging inner tray: coding on the inner padding paper of some high-end foods.

Core values:

Compliance with regulations: Meet the traceability requirements for primary packaging materials in the pharmaceutical and food industries.

Safety and hygiene: Non contact laser coding, pollution-free, suitable for clean environments.

4. Electronics and New Energy Industry (Special Applications)

Used for some special sheet-like functional materials.

Specific application:

Flexible Circuit Board (FPC): pagination and coding traceability of FPC.

Insulation material/thermal conductive silicone sheet: Mark the model, specifications, and other information on the sheet.

Battery polarizer: During the manufacturing process, the segmented polarizer is coded and traced (although the process requirements are extremely high, the principle is similar).

Core values:

Lean production: Identity management of expensive functional materials to achieve full process quality traceability

Detailed explanation of the workflow of the equipment

Automatic feeding and pagination: The equipment automatically sucks or lifts a stack of page shaped materials (such as 500 sheets of instruction manuals) into the pagination mechanism. By using techniques such as friction paging, suction paging, or ultrasonic paging, it is ensured that only the bottommost or topmost material is separated each time and accurately fed into the conveyor belt.

Visual positioning and correction:

The conveyor belt transports a single material to the visual camera below the coding station.

The camera quickly captures images of materials and identifies feature points or pre printed markings on the materials through algorithms.

The system calculates the deviation (X, Y, θ angle) between the current actual position of the material and the preset standard position.

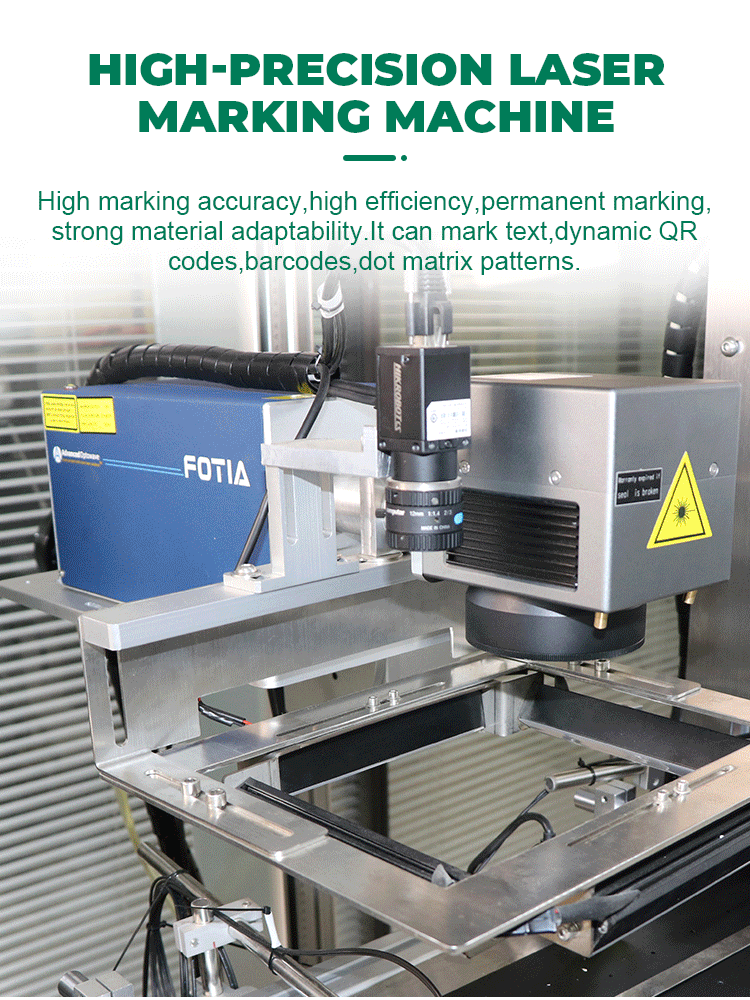

Dynamic coding:

The system sends the real-time position deviation value to the dock (laser).

The dock dynamically adjusts the coding position based on the deviation value to ensure that no matter how the material deviates, the code can be printed in the preset absolute position.

At the same time, the system calls variable data (such as serial number) from the database for coding.

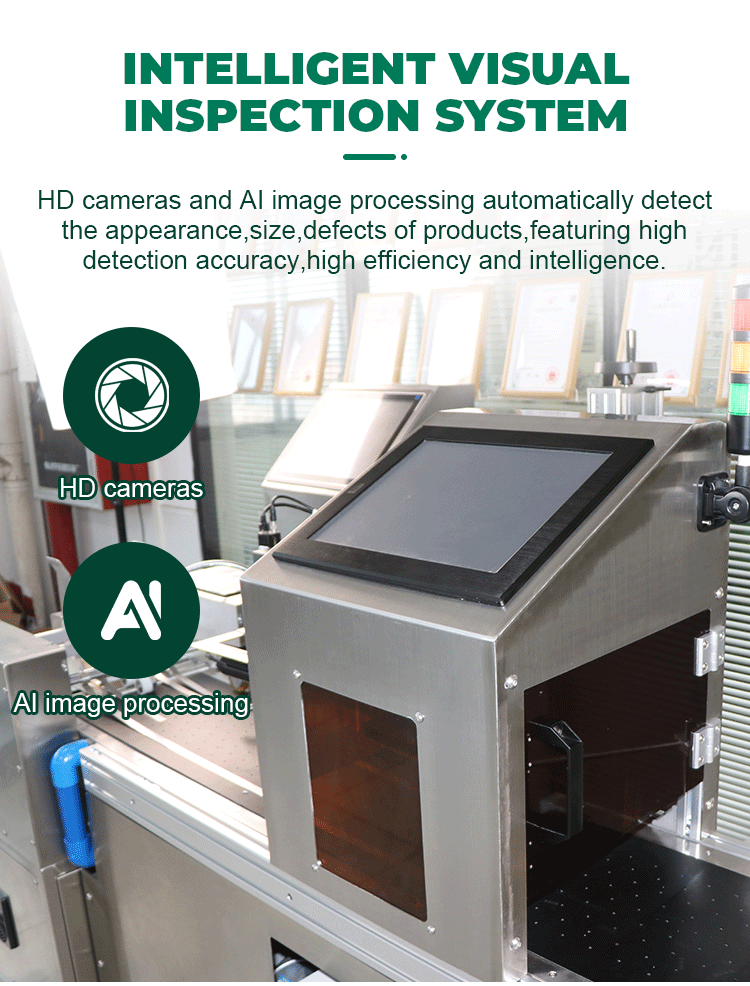

Online visual inspection:

After the coding is completed, the material immediately enters the testing station.

Another high-performance camera takes photos of the coding area.

AI visual inspection system judges the quality of coding:

Exist: Did you miss the code?

Correct content: Is the code content consistent with the data issued by the system?

Readable: Does the level of the QR code/barcode (such as A or B) meet the standard? Is OCR character recognition accurate?

Position accuracy: Is the coding position within the tolerance range?

Sorting and receiving:

The system controls the sorting device at the end based on the detection results (OK/NG) to separate qualified and unqualified products into different receiving bins.

All coding data, detection results, and images are uploaded to the MES/QMS system to form a complete data report.

ENQUIRYIntegrated device for pagination visual positioning, coding and detection

Chinese

Chinese English

English