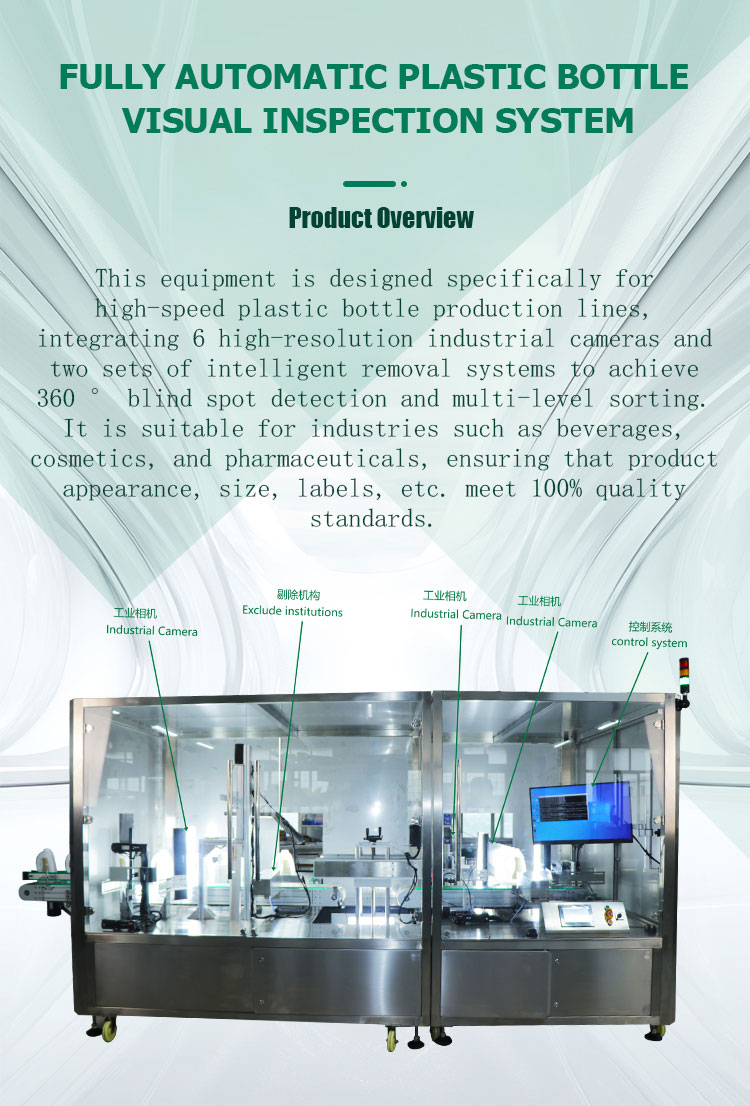

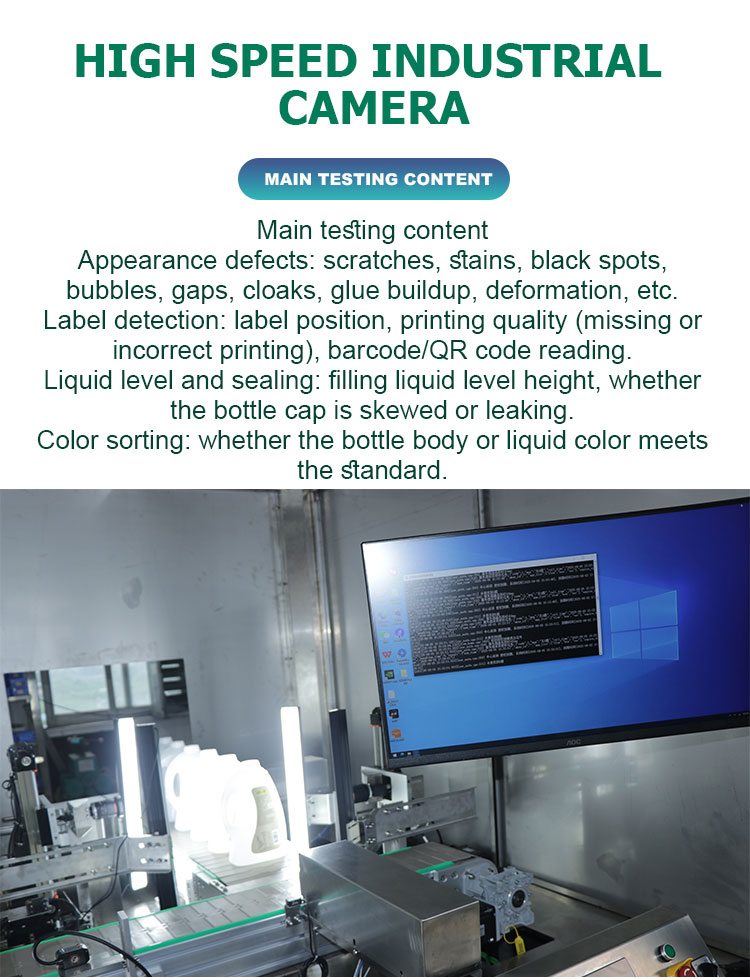

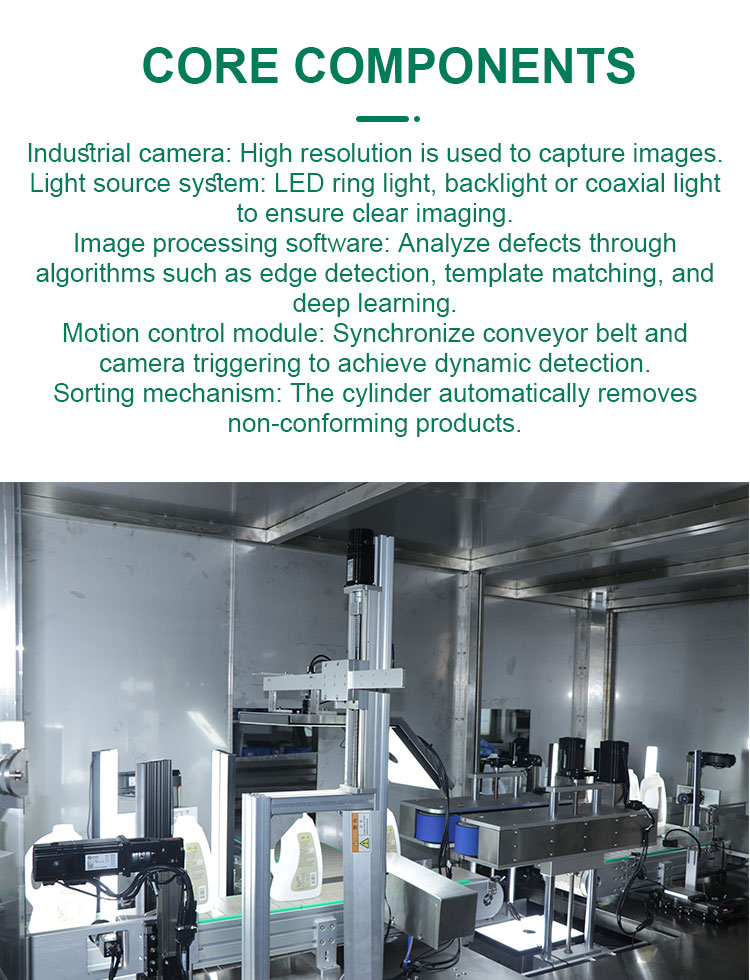

- Product description

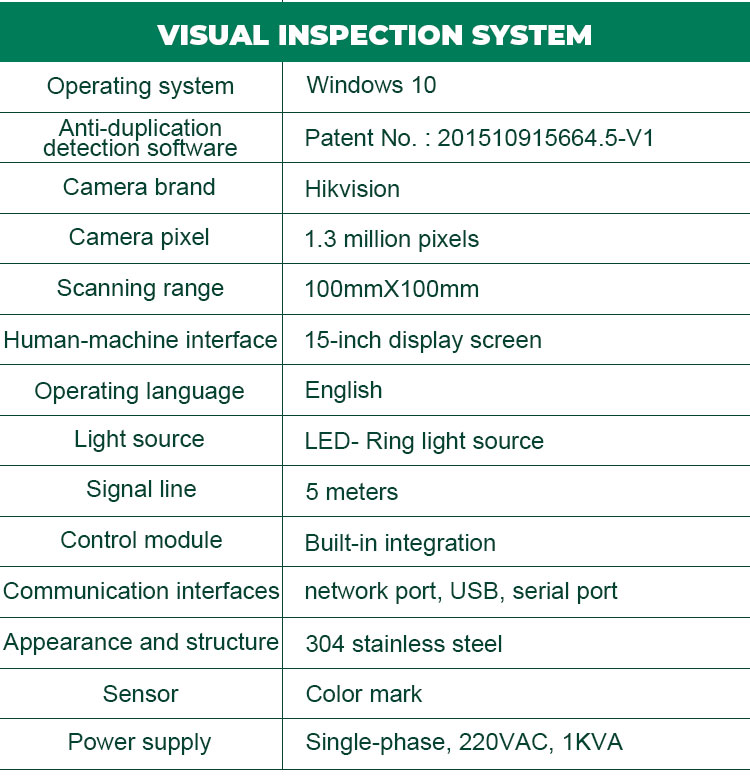

- Technical parameter

- Application field

- Sample display

1. Beverage industry

This is the most widely used and in high demand industry.

Testing content:

Liquid level height: Ensure consistent filling volume, no more or less.

Bottle cap defects: presence or absence of bottle caps, crooked caps, inadequate capping, and broken anti-theft rings.

Label detection: Check for the presence, misalignment, skewness, wrinkling, and printing defects (such as blurry dates and batch numbers) of labels.

Bottle mouth defects: whether there are gaps or cracks in the bottle mouth, and whether there is contamination on the inner wall of the bottle mouth.

Foreign objects in the bottle: whether there are impurities, suspended solids, black spots, etc. in the beverage.

Bottle defects: bubbles, scratches, stains.

2. Food industry (seasoning, edible oil, dairy products, etc.)

Similar to the beverage industry, but with extremely high requirements for hygiene and safety.

Testing content:

In addition to the common testing items in the beverage industry mentioned above, special attention is paid to the detection of foreign objects inside the bottle (such as hair, insect fragments, plastic debris) and the cleanliness of the bottle.

Ensure packaging sealing to prevent leakage and deterioration of oils, sauces, etc.

3. Pharmaceutical industry

This is the industry with the most stringent testing requirements, directly related to medication safety. Usually, compliance with regulations such as GMP (Good Manufacturing Practice) is required.

Testing content:

Sealing integrity: Check whether the bottle cap seal is absolutely tight to prevent the drug from getting damp or contaminated.

Foreign objects inside the bottle: detect extremely small glass fragments, metal particles, fibers, hair, etc. in the medicine or powder. This is of utmost importance in the pharmaceutical industry.

Liquid level/powder level: Ensure precise and error free filling.

Bottle body cracks: Even micrometer sized cracks must be detected, otherwise it will affect the sterile state.

Labeling and traceability: Ensure that drug labels, batch numbers, and expiration dates are 100% correct and clearly readable, achieving full traceability.

4. Daily chemical industry (cosmetics, personal care products, laundry products)

We place great emphasis on the appearance and consumer experience of our products.

Testing content:

Appearance aesthetics: Whether there are scratches, color differences, stains, shrinkage marks and other defects on the bottle body that affect its appearance.

Bottle cap and spray head: ensure that the pump head and spray head function normally without leakage and are assembled in place.

Labeling and packaging: The labeling requirements for high-end cosmetics are extremely high and cannot have any defects.

Filling volume: ensure that the filling height of face cream, lotion and other products is consistent.

5. Chemical industry (pesticides, chemicals, etc.)

Pay attention to safe packaging and leak prevention, while also ensuring correct labeling.

Testing content:

Sealing test: prevent the leakage of toxic and harmful chemicals, and ensure absolute sealing of the packaging.

Bottle wall thickness: Check whether the thickness of the bottle body is uniform and whether it can withstand the corrosion and transportation pressure of chemicals.

Label recognition: Ensure that the identification and instructions of hazardous materials are correct and error free, and prevent misuse.

ENQUIRYPlastic bottle visual inspection equipment

Chinese

Chinese English

English