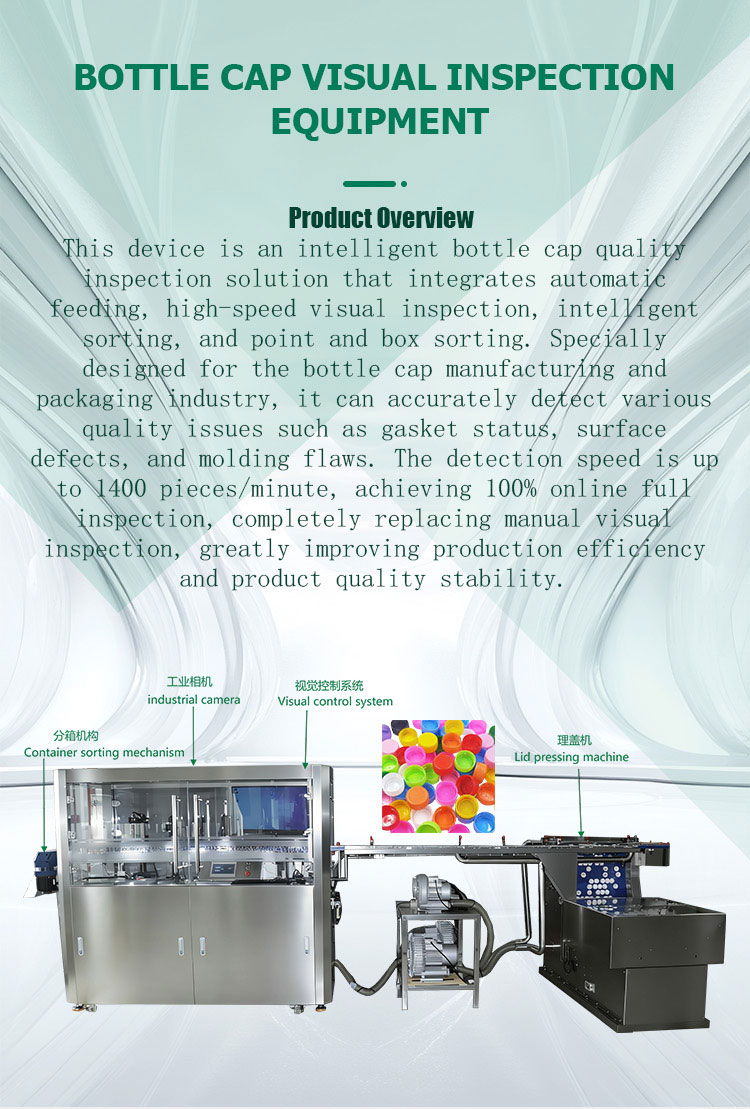

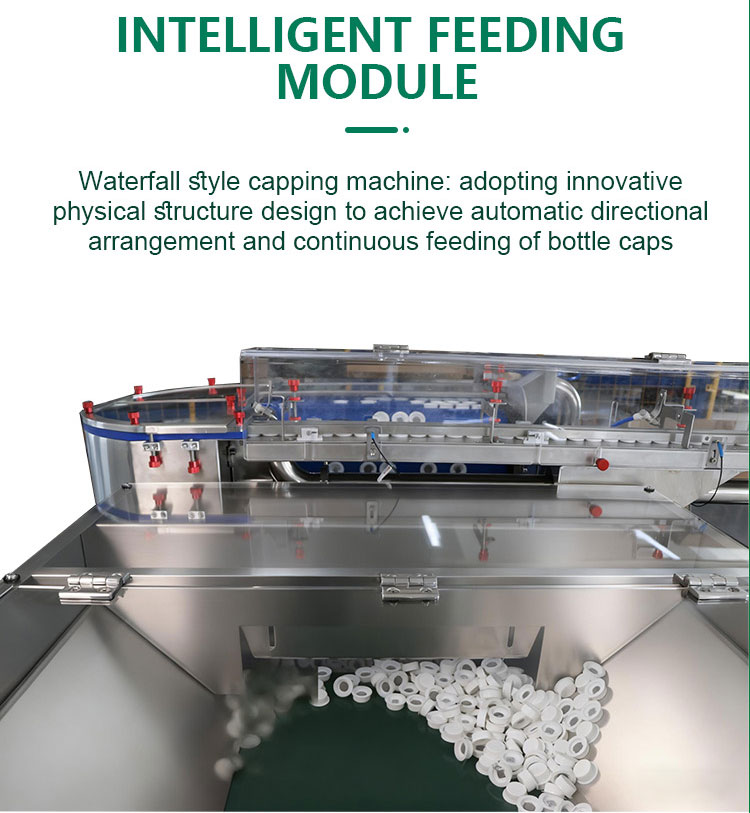

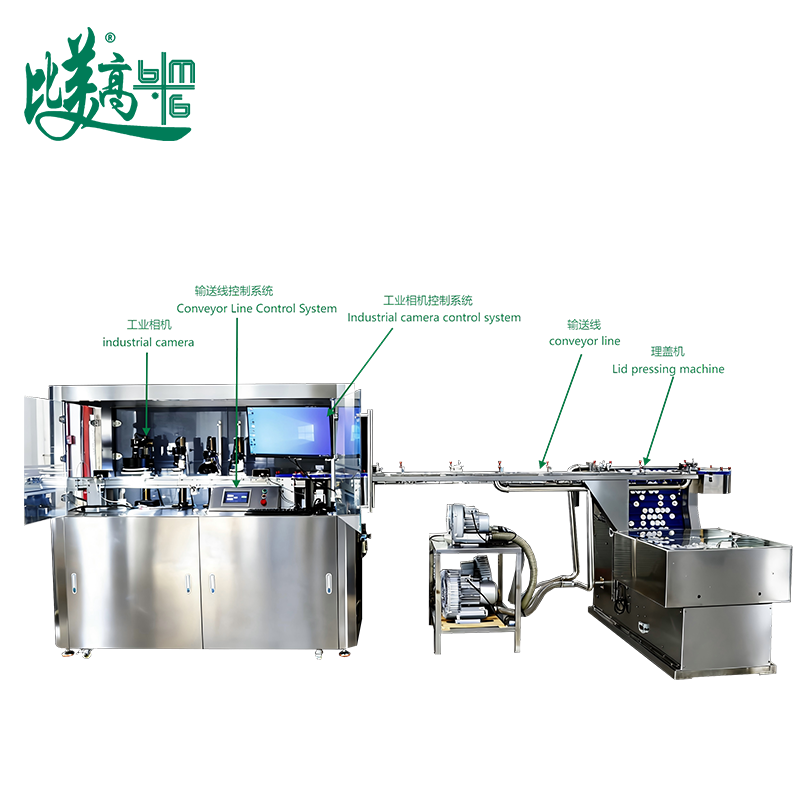

- Product description

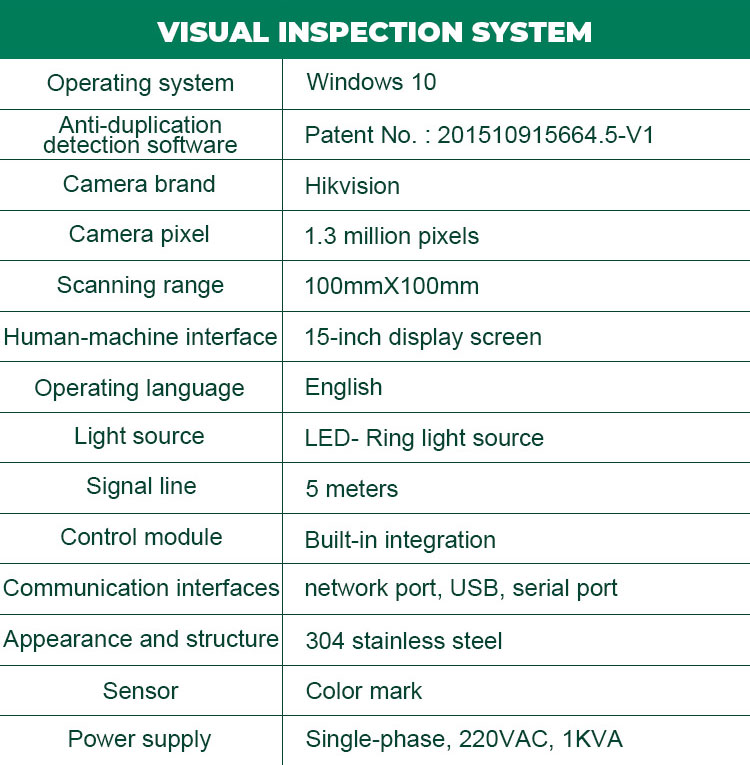

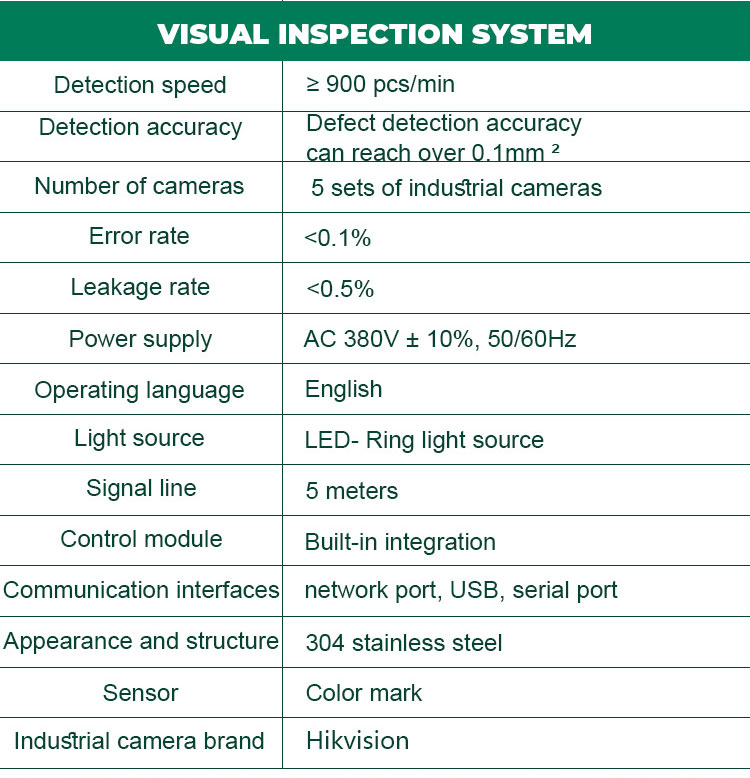

- Technical parameter

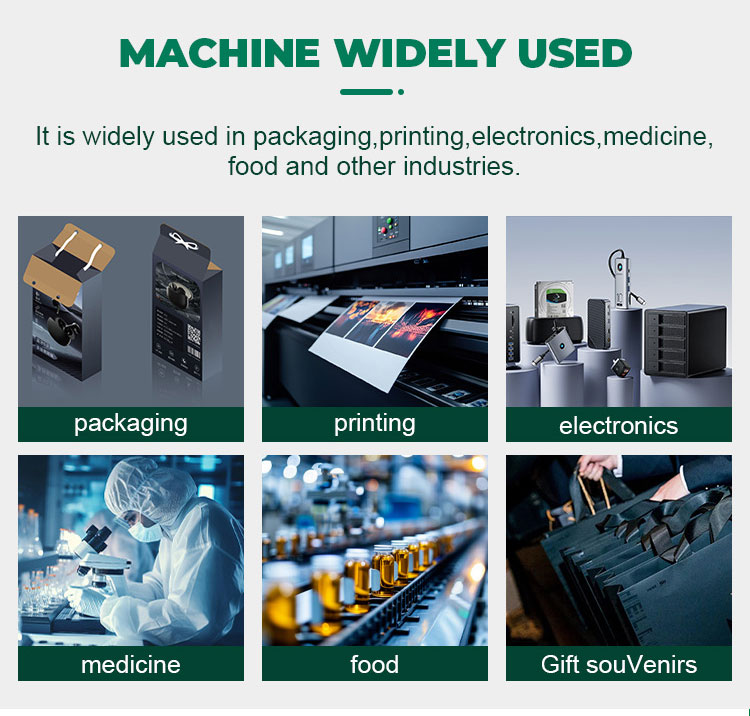

- Application field

- Sample display

This is the field with the largest and most concentrated demand for bottle cap visual inspection equipment, due to its huge production volume and high speed requirements.

Mineral water and purified water

Key inspection points: foreign objects, burrs, indentations on the lid, whether the sealing ring (pull ring) is in place, whether there is an anti-theft ring (broken bridge connection point), crooked lid, high lid, and sealing (indirectly judged by checking the fit gap between the lid and the bottle mouth).

Carbonated beverages (soda, soda water)

Testing focus: In addition to the common defects mentioned above, there is a high requirement for sealing to prevent carbon dioxide leakage from causing the beverage to become "flat". At the same time, pay attention to whether the gasket inside the cover is intact.

Tea drinks, fruit juice, functional drinks

Testing focus: Whether the bottle cap printing (logo, production date, shelf life) is correct, clear, and free of scratches; Is the color consistent; Prevent mixing of different types of bottle caps.

beer industry

Testing focus: whether the ripples on the Crown Cap are uniform and whether there is rust; The safety of opening the pull tab cover; Sealing testing is crucial to prevent oxidation and air leakage.

Dairy products (milk, yogurt, probiotic drinks)

Testing focus: The hygiene requirements are extremely high, and it is necessary to check whether there are impurities, hair, mosquitoes, etc. inside the cover; Is the aluminum foil sealing film of the yogurt cup sealed completely, without wrinkles or punctures.

ENQUIRYBottle cap visual inspection equipment

Chinese

Chinese English

English