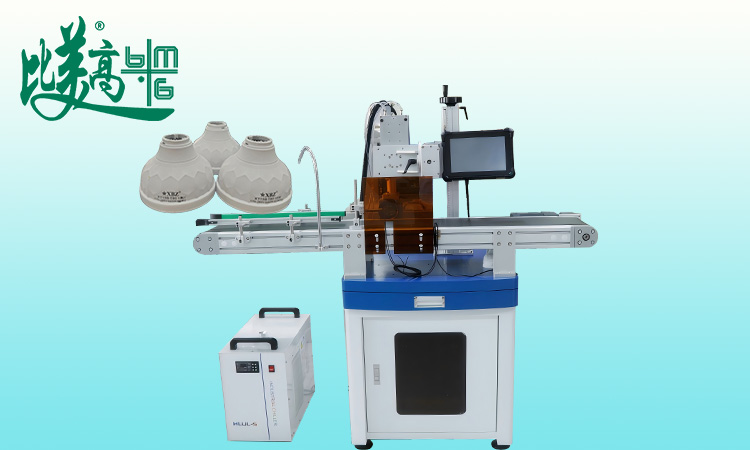

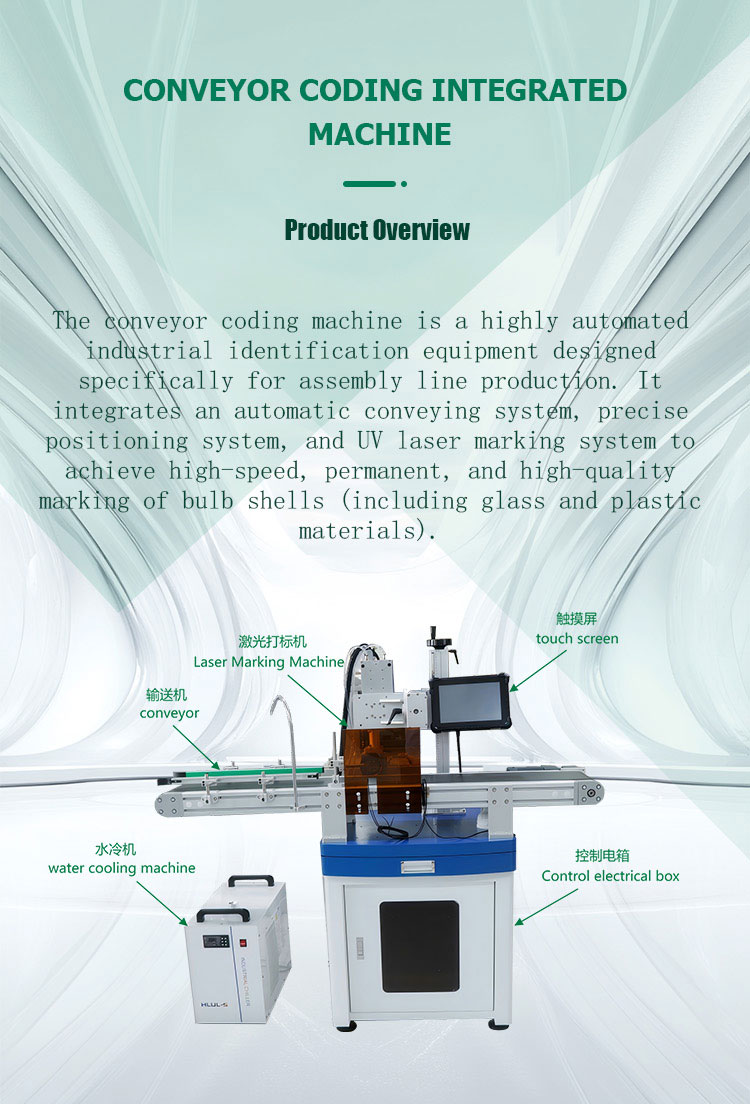

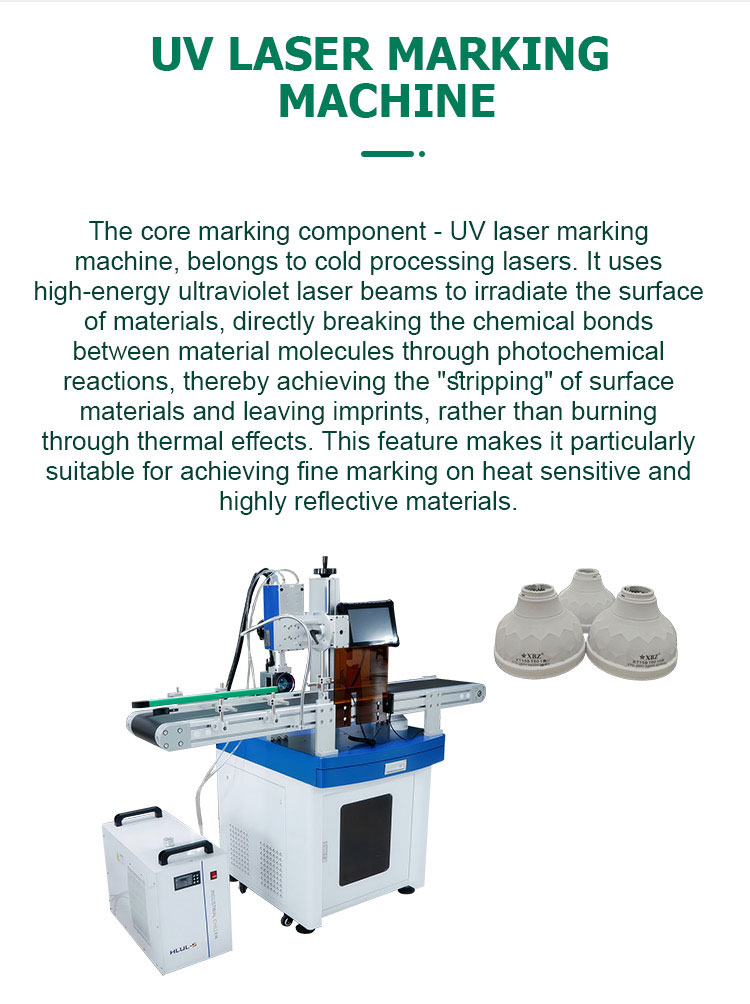

- Product description

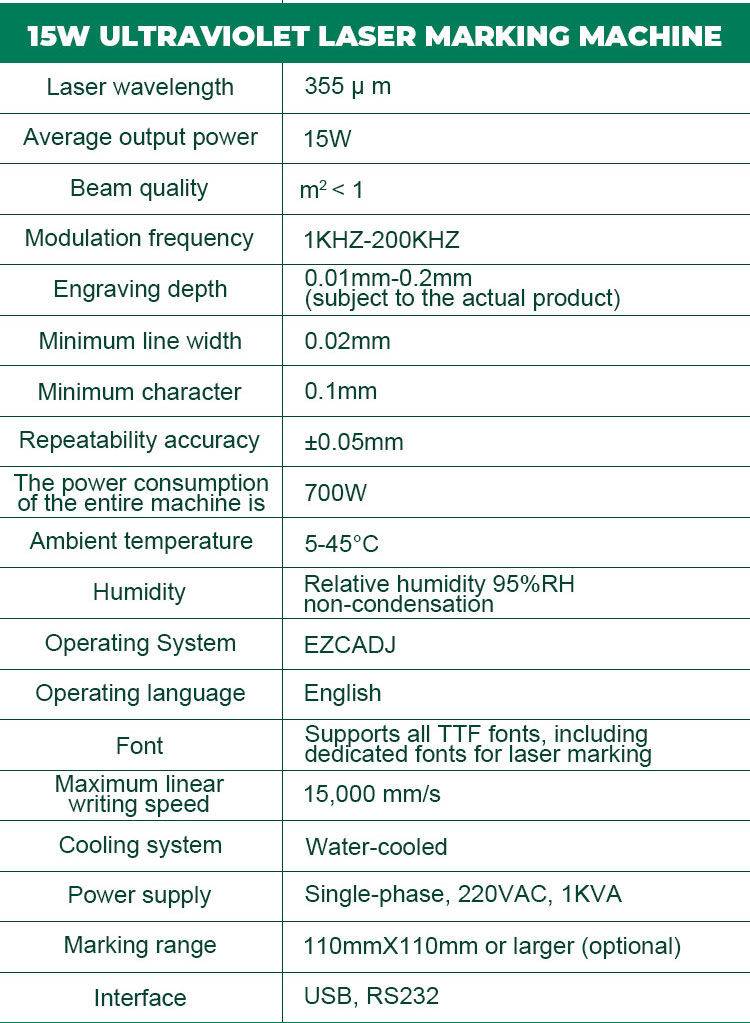

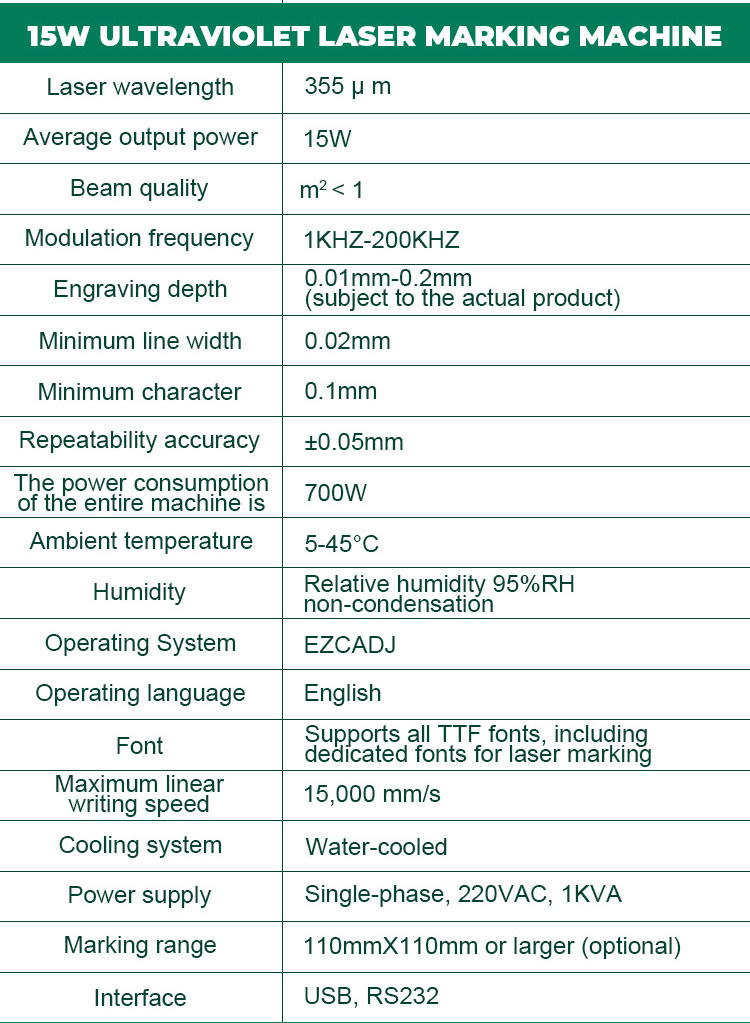

- Technical parameter

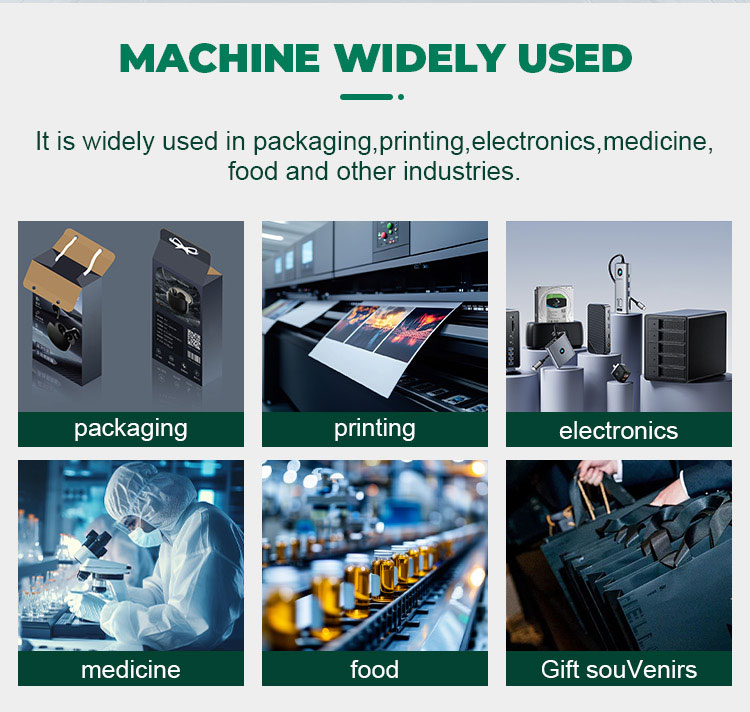

- Application field

- Sample display

PCB/FPC Marking:

Content: Mark QR codes, barcodes, serial numbers, logos, etc. on the circuit board.

Advantages: Clear and permanent markings, no damage to fragile circuits and copper foil, minimal thermal impact, no deformation or yellowing of the board.

Glass marking and cutting:

Content: LOGO, text, and patterns on surfaces such as phone covers, camera lenses, smartwatch glass, and touch screens.

Advantages: It can achieve crack free and smooth edge marking and cutting, and the marking effect can be pure white, dark black or transparent frosted, with high aesthetic appeal.

Marking of plastic parts:

Content: Identification on plastic components inside mobile phone cases, chargers, headphones, laptops, etc.

Advantages: Unlike fiber laser, which causes plastic to melt or produce a burnt smell due to heat, the marking has high contrast and is clean and beautiful.

Wafer and chip marking:

Content: Engraving tiny traceability codes, models, and other information on silicon wafers and IC chips.

Advantages: With extremely high precision, it can make clear markings in micrometer level space, making it an indispensable traceability tool in the semiconductor industry.

2、 Medical and Medical Devices

The medical industry has strict requirements for the permanence, safety, and accuracy of markings.

Medical device labeling:

Content: UDI (Unique Device Identification) codes and serial numbers on surgical instruments, orthopedic implants (such as titanium alloy screws, joints), dental implants, etc.

Advantages: The markings are non-toxic, pollution-free, corrosion-resistant, permanently clear, and will not have any negative impact on the mechanical properties and biocompatibility of the device.

Drug packaging and medical device packaging:

Content: Mark the production date, batch number, and expiration date on packaging such as medication bottles, syringes, and infusion bags.

Advantages: Non contact, no debris contamination of packaging; The label is soft and will not puncture the packaging, causing leakage.

3、 Food, Beverage, and Packaging Industry

Mainly used to achieve product traceability and anti-counterfeiting.

Plastic packaging labeling:

Content: Mark the date and batch number on PET bottles, PE bottles, yogurt cup lids, and food packaging films.

Momentum: Fast speed, clear markings, will not penetrate thin-walled packaging.

Labeling of glass bottles/metal cans:

Content: Label production information on the bottom or side of beer bottles and beverage cans.

Advantages: Beautiful and durable markings, resistant to friction and liquid erosion.

4、 Daily cosmetics and luxury goods

Cosmetics packaging:

Content: Mark LOGO and batch number on glass perfume bottle, plastic cream bottle and lipstick tube.

Advantages: Enhance product quality, achieve exquisite frosted or dark markings, and have no chemical pollution.

Luxury Mark:

Content: Fine carving on metal watch cases, straps, jewelry, eyeglass frames, etc.

Advantage: It can achieve complex patterns and fine text, meeting the ultimate pursuit of luxury goods for craftsmanship and aesthetics.

Advantages: Beautiful marking, wear-resistant, and non fading.

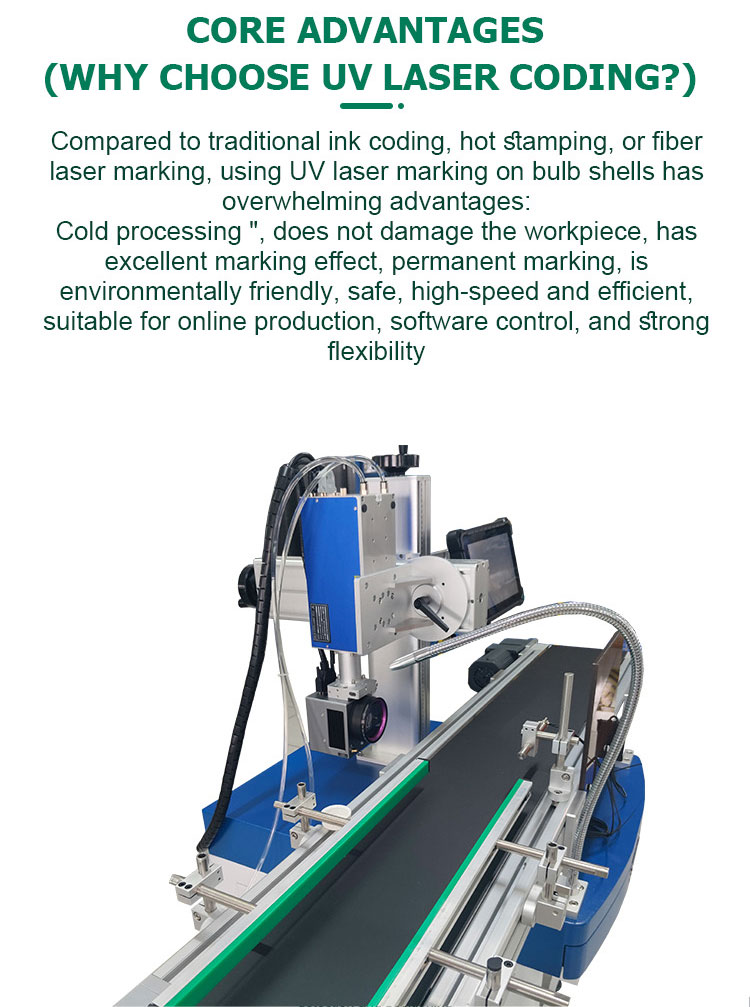

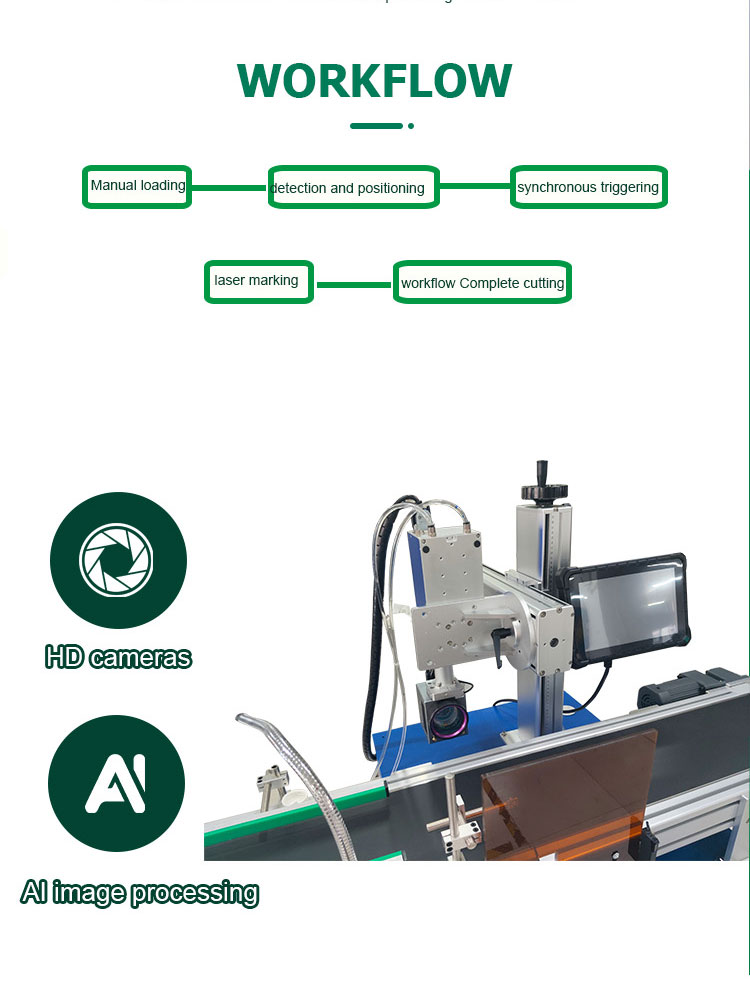

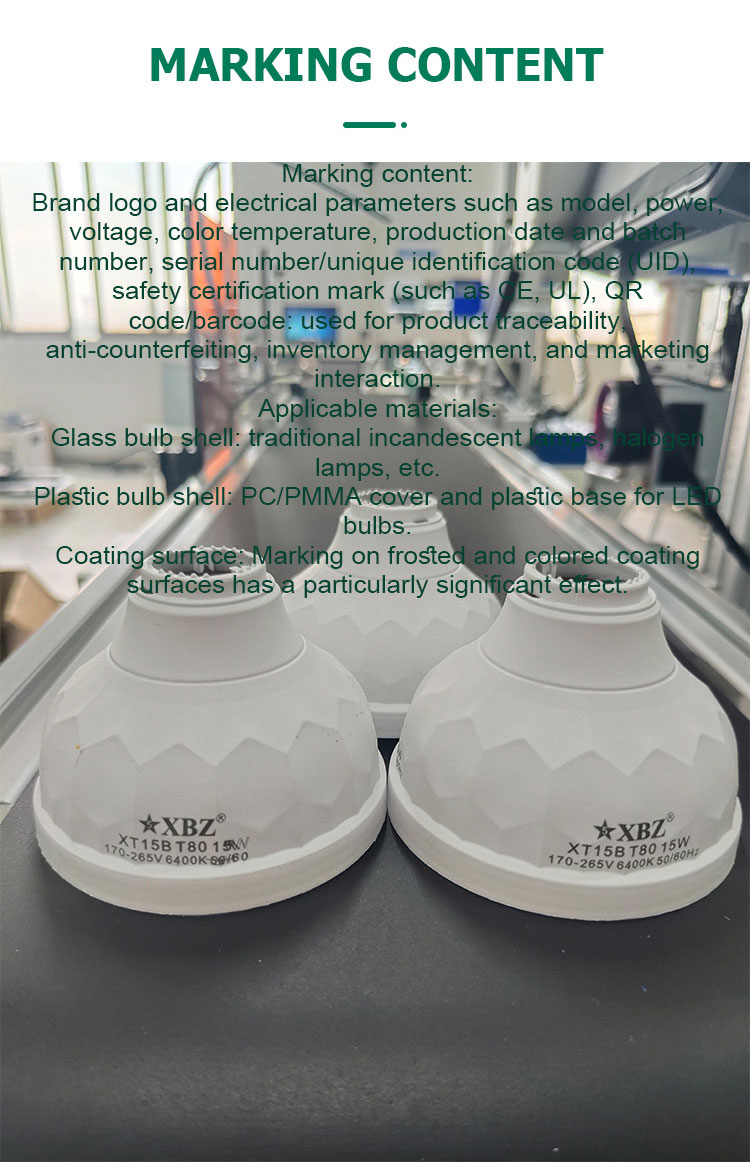

ENQUIRYConveyor coding integrated machine

Chinese

Chinese English

English