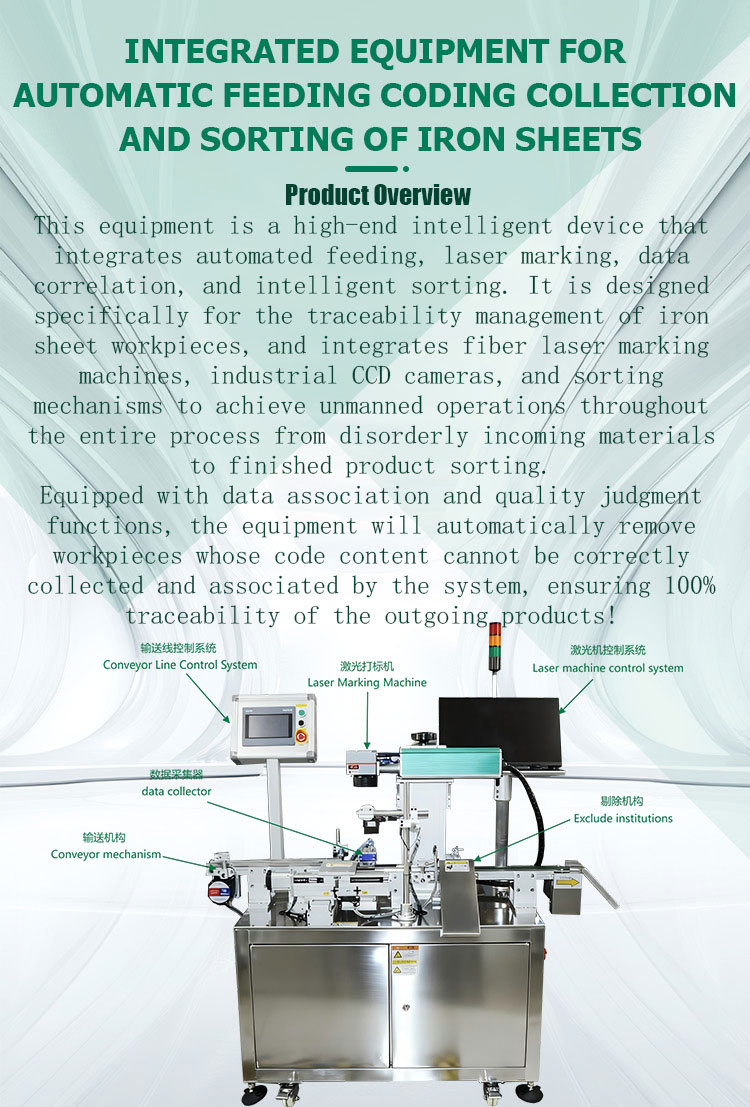

Iron sheet automatic feeding, marking, collection and sorting machine

Product number:

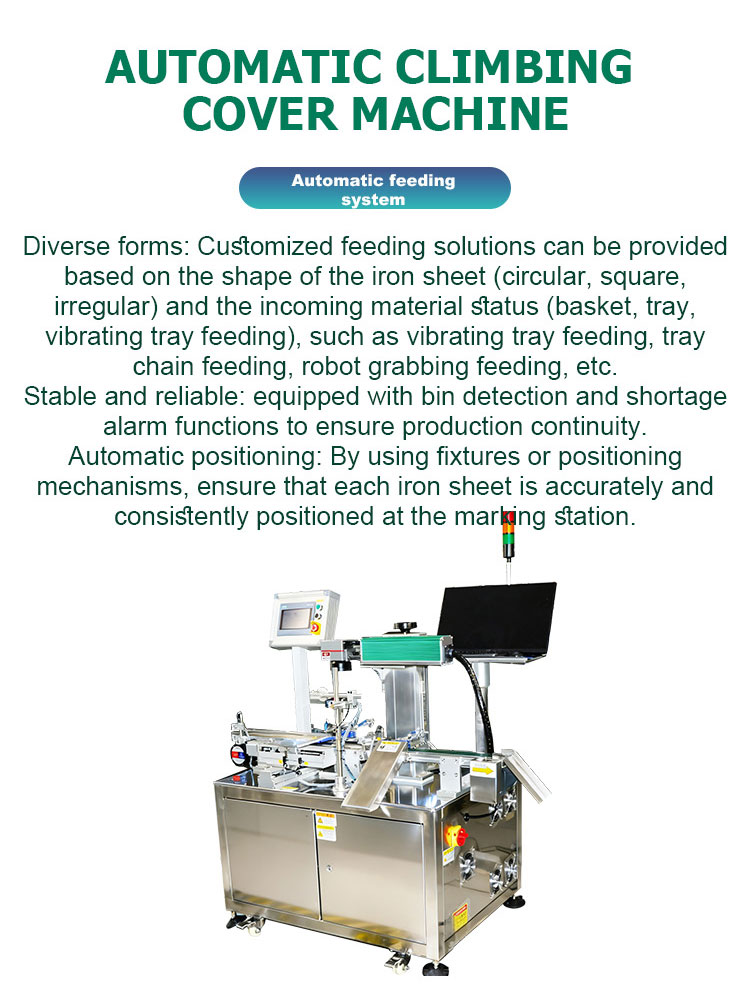

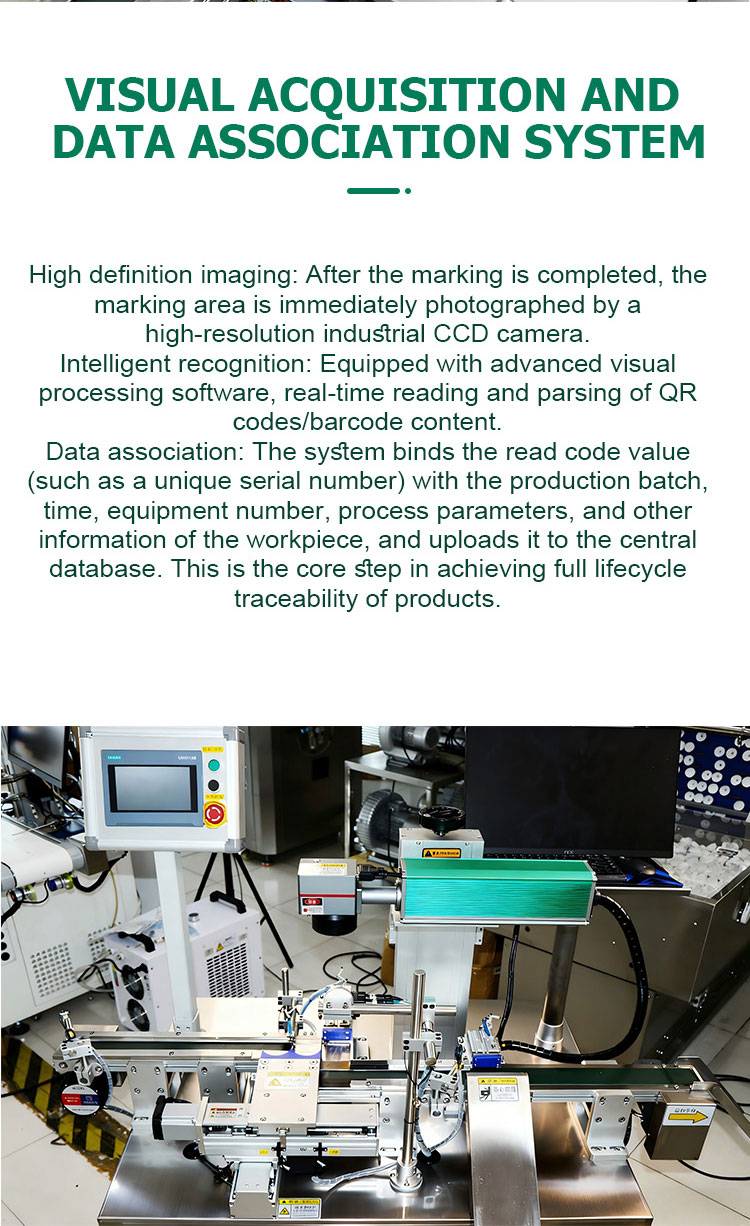

- Product description

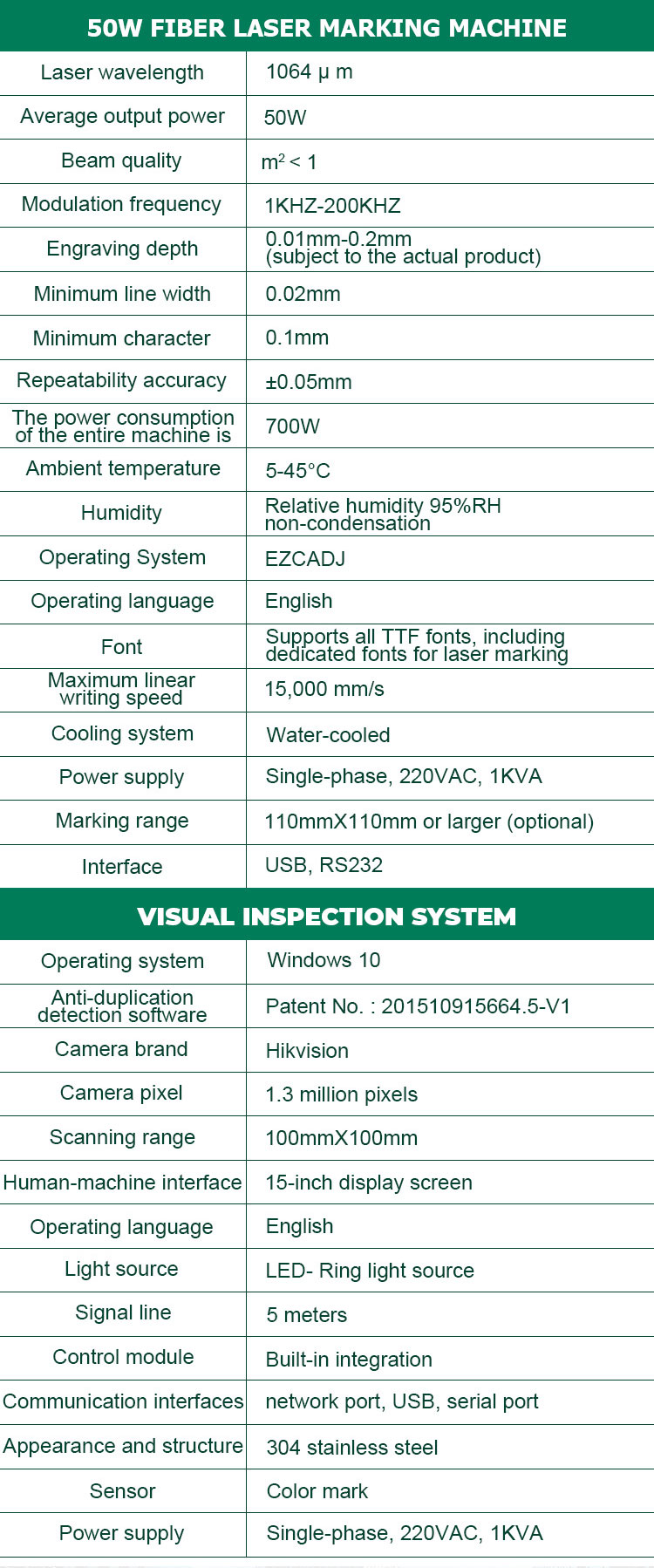

- Technical parameter

- Application field

- Sample display

Core application areas

1. Automotive and component manufacturing

Application Scenario:

Engine/transmission parts: Mark VIN code, part number, batch number on iron components such as cylinder block, piston, gear, etc.

Chassis and safety components: Trace and label key safety components such as brake pads, bearings, and steering knuckles.

Electronic control system: Mark QR codes and serial numbers on the ECU housing and sensor housing.

Addressing pain points: achieving full lifecycle traceability of components, meeting strict quality system requirements in the industry (such as IATF 16949), and eliminating counterfeit and inferior products.

2. Precision Hardware and Tools

Application Scenario:

Standard parts: Mark and automatically sort large quantities of parts such as screws, nuts, bolts, washers, etc. based on brand, specifications, and materials.

Cutting tools/molds: Mark the model, specifications, and QR code on the drill bit, milling cutter, blade, and mold for easy inventory management and lifespan tracking.

Locks/Bathroom: Mark internal iron parts such as lock tongues and faucet valve cores for anti-counterfeiting and assembly traceability.

Addressing pain points: Replace easily worn ink coding and labels, provide permanent markings, and achieve rapid automated sorting and packaging of small products.

3. Electronic and electrical components

Application Scenario:

Semiconductor lead frame: Marking traceability codes on iron or alloy lead frames that carry chips.

Electrical casing and structural components: Mark the model and serial number on internal metal parts such as motor casing, heat sink, relay base, etc.

PCB metal substrate: Marking metal circuit boards such as aluminum substrates.

Addressing pain points: Meeting the marking requirements for miniaturization and high integration of electronic products, with clear markings and no chemical pollution, suitable for clean workshop environments.

4. Industrial equipment and machinery manufacturing

Application Scenario:

Pump/valve/compressor: Mark the brand logo, model, and factory number on the casing, flange, and other locations.

Mechanical structural components: Mark unique identification codes on machined sheet metal parts, bearing seats, gearboxes, etc.

Automated robot components: Marking on mechanical arms, guide rails, and other parts for asset management and maintenance traceability.

Addressing pain points: Establishing digital "ID cards" for large and heavy equipment and their components to facilitate production management, warehousing logistics, and equipment maintenance.

5. Medical devices and surgical tools

Application Scenario:

Surgical instruments: Unique serial numbers are marked on reusable tools such as surgical scissors, pliers, and bone drills to track usage frequency, sterilization cycle, and responsible personnel.

Medical equipment casing and parts: Mark the internal and external iron components of hospital beds, monitors, and diagnostic equipment.

Implant packaging information: Mark on relevant metal trays or accessories.

Addressing pain points: Meeting unique labeling regulations for medical devices such as FDA/UDI, achieving strict aseptic management and traceability, and ensuring patient safety.

ENQUIRYIron sheet automatic feeding, marking, collection and sorting machine

Chinese

Chinese English

English