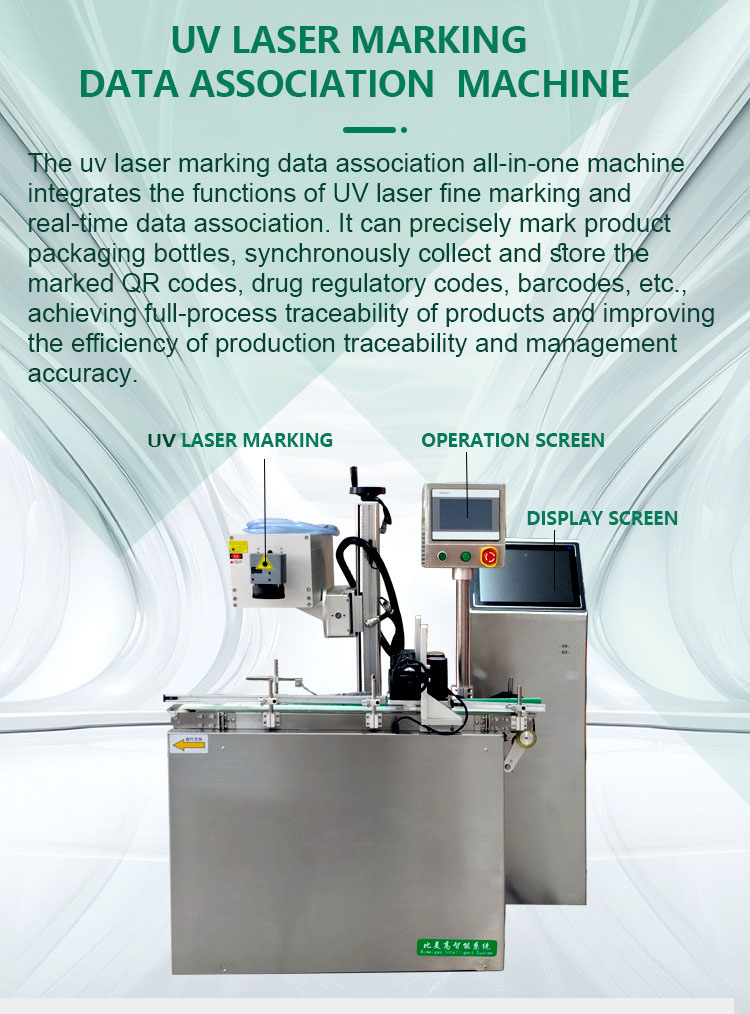

Integrated equipment for bottle conveying and coding

Product number:

- Product description

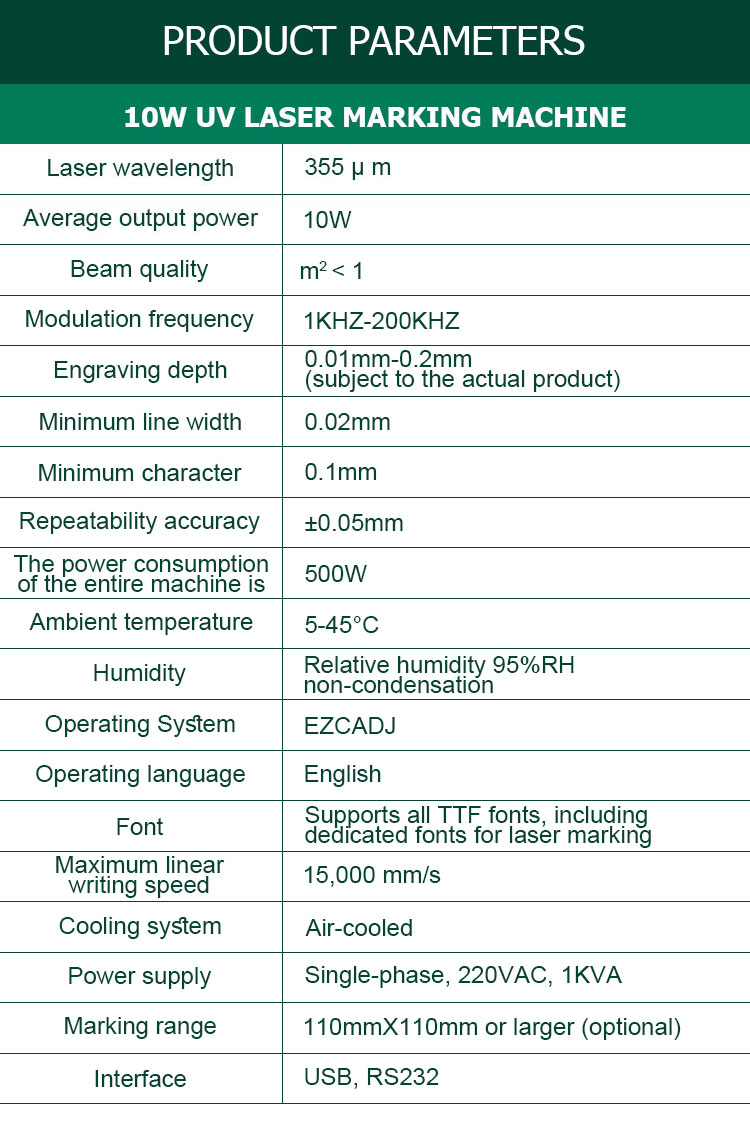

- Technical parameter

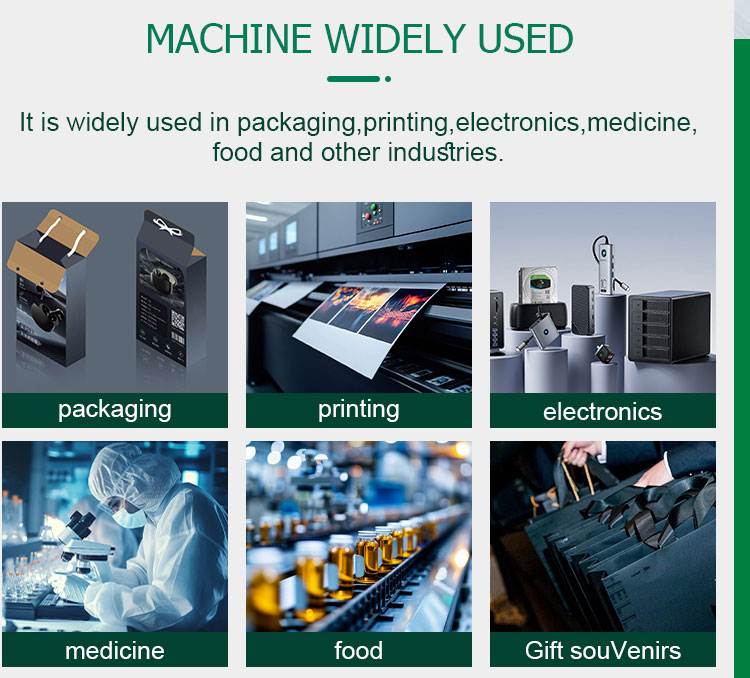

- Application field

- Sample display

Core application industry

1. Electronic components and semiconductor industry (ultra-high precision and speed requirements)

This is the most valuable application area for flying UV laser marking machines, with extremely high requirements for accuracy, speed, and thermal control.

Specific application:

PCB board marking: Printing serial numbers and QR codes on moving circuit boards (PCB, FPC). The cold processing characteristics of UV laser will not damage precision circuits.

Chip and component labeling: During SMT surface mounting, high-speed chips, resistors, capacitors, etc. are labeled to achieve item level traceability.

Mobile phone components: Mark the camera module, phone frame, glass cover and other components with precise positioning and no thermal damage.

Core values: Ultimate efficiency (perfectly matched with production line rhythm), ultra-fine marking (characteristic of UV laser), stress free cold processing (not damaging fragile electronic components).

2. Food and beverage packaging industry (high-speed coding demand)

This is one of the most widely used fields, requiring online identification for every product.

Specific application:

Plastic bottle cap/body: On the high-speed filling line, label the production date, shelf life, and batch number of flowing mineral water bottles and beverage bottles. UV marking is environmentally friendly, pollution-free, and has high contrast.

Glass bottle: Label the bottom or side of beer bottles, soy sauce bottles, and cosmetics bottles.

Soft packaging: Code on aluminum foil bags and plastic film packaging (such as snack bags). UV laser can effectively process these materials.

Core values: high speed (up to hundreds or even thousands per minute), environmental protection (replacing ink coding, no chemical pollution), permanent clarity (marks are not easily worn out).

3. Pharmaceutical and Medical Device Industry (Safety, Compliance, and High Speed Requirements)

The industry has mandatory requirements for traceability and production speeds are getting faster and faster.

Specific application:

Medical packaging: Flight label the electronic supervision code, batch number, and expiration date of drugs on drug boards (PTP aluminum foil), drug bottles, and injection bags.

Medical devices: Mark UDI (Unique Device Identification) codes on catheters, syringes, and packaging bags.

Core values: Meet the mandatory traceability requirements of regulations, ensure 100% coding rate under high-speed production, and ensure safety and hygiene (contactless, no consumables).

4. Daily chemical and cosmetics industry (beauty and high-speed demand)

Specific application:

Plastic packaging: mark LOGO, batch number and limited date on shampoo bottle, lotion bottle, lipstick tube and cosmetics shell.

Glass bottles: perfume bottles and skin care bottles.

Core value: Marking exquisite high-end, enhancing product grade; Adapt to the rhythm of high-speed filling lines; Variable content, suitable for multi batch and small batch production.

5. Wire, cable and pipeline industry (continuous coding requirement)

This is a special but important application, and the product itself is continuous.

Specific application:

Cable marking: Label the brand, specifications, meters, and certification marks on wires, data cables, and insulation at regular intervals.

Plastic hoses: marked on medical hoses and industrial pipelines.

Core value: Achieving periodic coding of continuous materials is key to product identity and compliance.

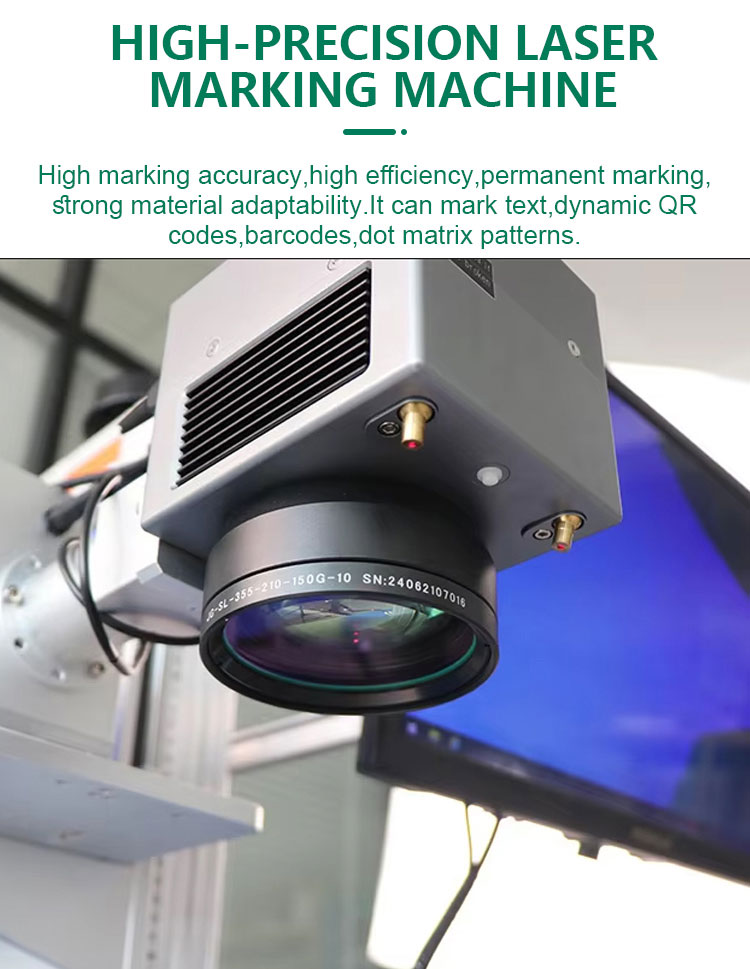

The working principle and advantages of flight marking technology

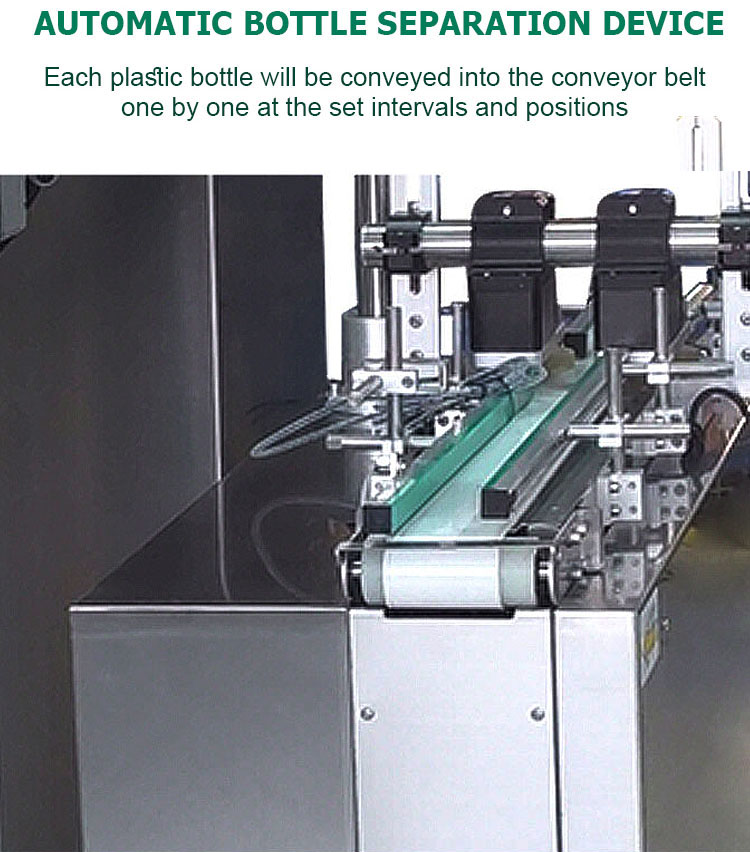

Product movement, laser head fixation: The product moves uniformly on the conveyor belt, and the UV laser marking head is fixed above.

Synchronous trigger: The sensor (usually a photoelectric sensor) detects the arrival of the product and sends a trigger signal to the marking system.

Delay calculation and dynamic marking:

The system accurately calculates the delay based on the speed of the conveyor belt, the distance between the header and the sensor.

When the product moves directly below the marking head, the system controls the high-speed galvanometer to start working.

The oscillation of the vibrating mirror compensates for the movement speed of the product, resulting in static and non deformed text and patterns on the surface of the moving product.

Complete marking: After marking is completed, the product continues to flow to the next process (such as packaging and filling).

ENQUIRYIntegrated equipment for bottle conveying and coding

Chinese

Chinese English

English