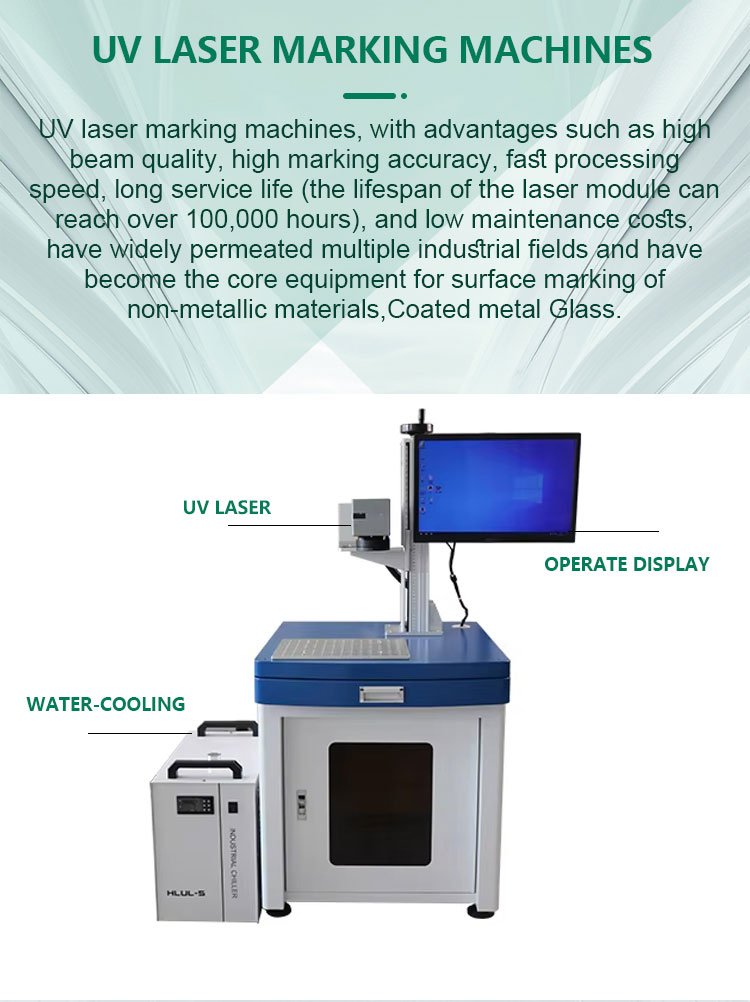

- Product description

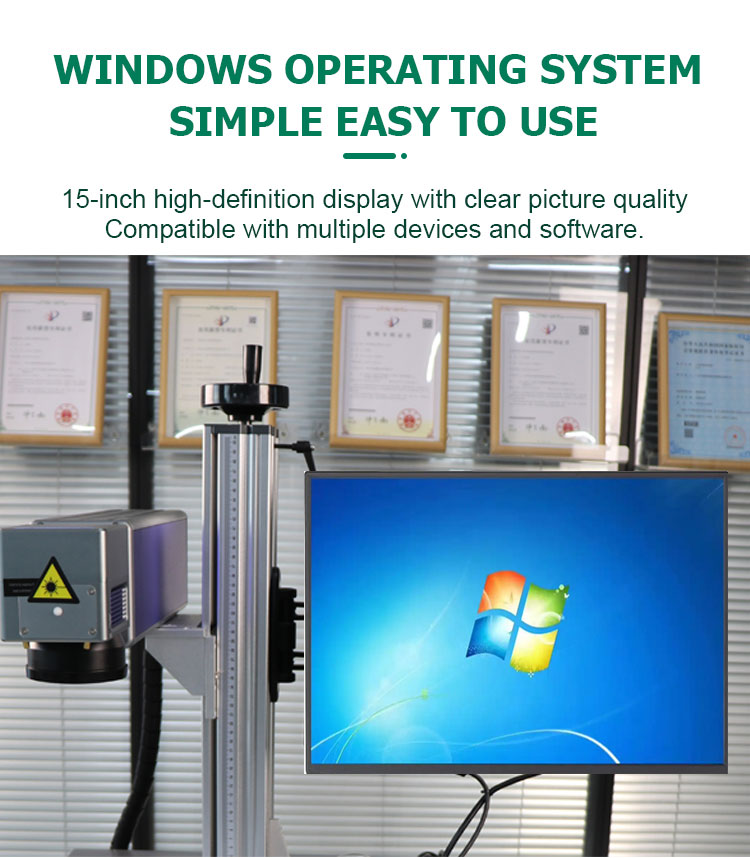

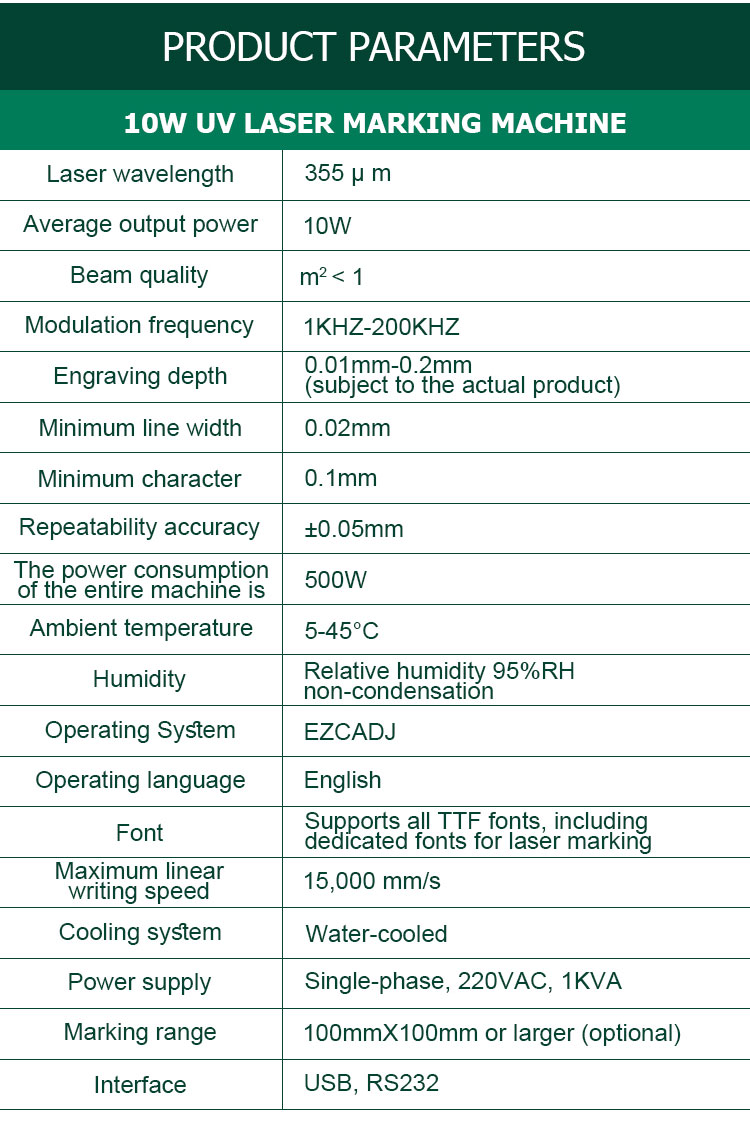

- Technical parameter

- Application field

- Sample display

Core application industry

1. Consumer electronics and semiconductor industry (ultra-high precision demand)

This is the core application area of UV laser marking machines, with almost stringent requirements for accuracy and thermal control.

Specific application:

Glass marking: mobile phone glass back cover, camera protective glass, QR code on tablet screen LOGO。 UV laser can produce white codes on glass without cracking.

PCB board marking: Mark serial numbers and QR codes on the surface of flexible circuit boards (FPCs) and flexible flex boards. UV cold processing will not damage precision circuits and sensitive electronic components.

Chip marking: marking extremely small characters on the surface of chip packaging.

Plastic casing: Fine patterns and text on phone casings, headphones, and smartwatch cases. UV marking will not cause plastic thermal deformation or produce a burnt smell.

Core values: "Cold processing" does not generate thermal stress, does not damage the substrate, has clear and beautiful markings, and meets the extremely high appearance and reliability requirements of consumer electronics products.

2. Pharmaceutical and Medical Device Industry (Safety and Compliance Requirements)

The industry has mandatory requirements for the permanence, non toxicity, and cleanliness of markings.

Specific application:

Medical devices: UDI (Unique Device Identification) codes on surgical instruments, implants, catheters, and stainless steel containers. UV marking is burr free, smooth, and meets medical grade standards to prevent bacterial growth.

Pharmaceutical packaging: drug packaging aluminum foil (PTP foil), PVC material, batch number, expiration date, and electronic drug supervision code on plastic bottles and capsules. UV marking has no chemical residue and is very environmentally friendly and safe.

Glassware: Scale and number on experimental vessels and injection bottles.

Core values: Meet the traceability requirements of FDA, NMP and other regulations for medical devices and drugs, mark with good biocompatibility, safe and non-toxic.

3. Food and cosmetics packaging industry (aesthetic and safety requirements)

Mainly used for high-end packaging to enhance product quality and safety.

Specific application:

Plastic packaging: mark production date, shelf life and batch number on cosmetics bottle caps, lotion bottles, food packaging bags made of PE, PET, PP and other materials. The effect is clear and more hygienic than ink coding.

Glass bottles: logos and decorative patterns on the surface of perfume bottles, high-end wine bottles, cosmetics bottles, jam bottles.

Metal packaging: Fine patterns on lipstick tubes and cosmetic covers.

Core value: High end, clear, and wear-resistant marking effect; No consumables, no pollution, in compliance with hygiene and safety standards for food and cosmetics packaging.

4. Precision hardware and tool industry (high contrast requirement)

Suitable for metal parts with special requirements for marking contrast and precision.

Specific application:

Hardware tools: High contrast black markings, such as brand name, specifications, and models, are printed on hardware components that have been oxidized or electroplated on the surface.

Electronic accessories: QR codes and logos on the phone frame, buttons, metal backplate, and aluminum alloy shell.

Jewelry: Carving extremely small text and patterns on precious metals, platinum, and platinum.

Core value: The ability to make clear, high contrast markings, aesthetically pleasing, and wear-resistant without damaging the surface treatment of the material (such as the oxide layer).

5. Other special materials industries

UV laser, due to its unique processing characteristics, can also handle materials that are difficult for other lasers to handle.

Specific application:

Ceramic materials: electronic component substrates, ceramic watch cases, and decorative ceramic marking.

Composite materials: marking on the surface of carbon fiber materials.

The core advantages of cabinet type UV laser marking machine

Advantages of "cold processing": Almost no thermal impact, will not cause material deformation, deterioration or burn marks, especially suitable for heat sensitive materials.

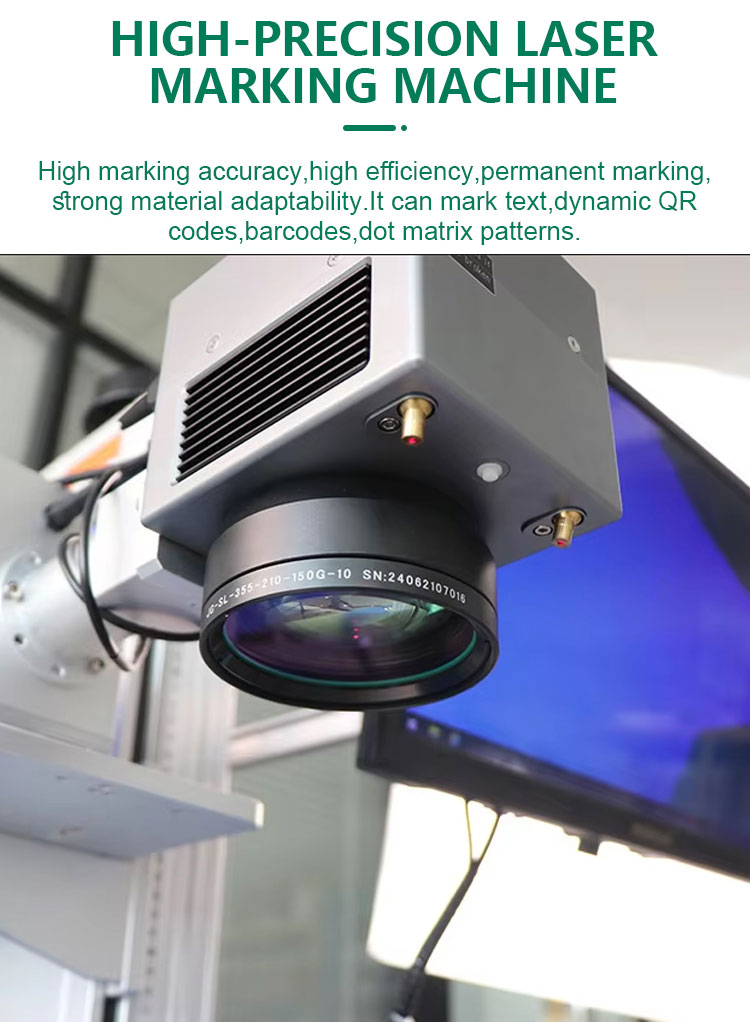

Extremely high processing accuracy: short wavelength, extremely small focused spot, capable of ultra fine marking (<10 μ m), achieving micro carving in the millimeter range.

Wide material adaptability: particularly adept at handling glass, plastic, ceramics, as well as various metals and films.

High contrast marking: capable of producing high contrast markings on various material surfaces (such as blackening on metal and whitening on glass), with excellent visual effects.

High safety and cleanliness: The enclosed cabinet can effectively prevent laser leakage, protect the safety of operators, and prevent dust to ensure the cleanliness of the marking process, making it very suitable for dust-free workshops.

ENQUIRYCabinet style UV laser printer

Chinese

Chinese English

English