Pen case automatic feeding and printing integrated equipment

Product number:

- Product description

- Technical parameter

- Application field

- Sample display

1. Stationery manufacturing and pen making industry (the most core and direct application)

This is the most important and fundamental application market for this device. Almost all types of pen cases can be processed with this device.

Specific application:

Neutral pen/ballpoint pen case: This is the largest application category, where brand names (such as Morning Light and Deli) are laser engraved on the pen case LOGO、 Model, specifications, etc.

Pen holder: Carving intricate logos, patterns, and even personalized signatures on metal or high-end plastic pen holders to enhance product quality.

Marking pen/whiteboard pen case: Mark brand information and model.

Pencil holder: Marking on plastic or composite pencil holders.

Core values:

Brand identification and anti-counterfeiting: Permanent laser marking is an important means of brand identification and anti-counterfeiting, which cannot be easily erased.

Improving product aesthetics: Compared to traditional screen printing or labeling, laser marking has a more textured, wear-resistant, and non shedding appearance.

Implementing automated production: replacing inefficient and error prone manual placement and labeling, significantly improving production line efficiency and reducing costs.

2. Gift and Promotion Industry

Many pen products are used as business gifts, conference souvenirs, or promotional gifts.

Specific application:

Customized gift pen: Carving personalized information such as the client's company logo, slogan, meeting name, date, etc. on the pen case.

Promotional gift pen: Quickly add specific patterns or text to promotional activities.

Core values:

Satisfy personalized customization: Automated equipment can easily achieve "one code, one change" and quickly respond to small and multi batch customized orders.

High precision and aesthetics: The laser engraved patterns are delicate and beautiful, which can better showcase the customer's brand image.

3. High end manufacturing and special industries

Some special-purpose pens also require such processing.

Specific application:

Medical pen: Marking hospital names or department information on pens specifically designed for doctors and nurses, which must meet cleanliness requirements.

Industrial pen (such as metal marker pen): used for marking durable and sturdy marks.

Core values: permanent identification, professionalism, and compliance with industry regulations.

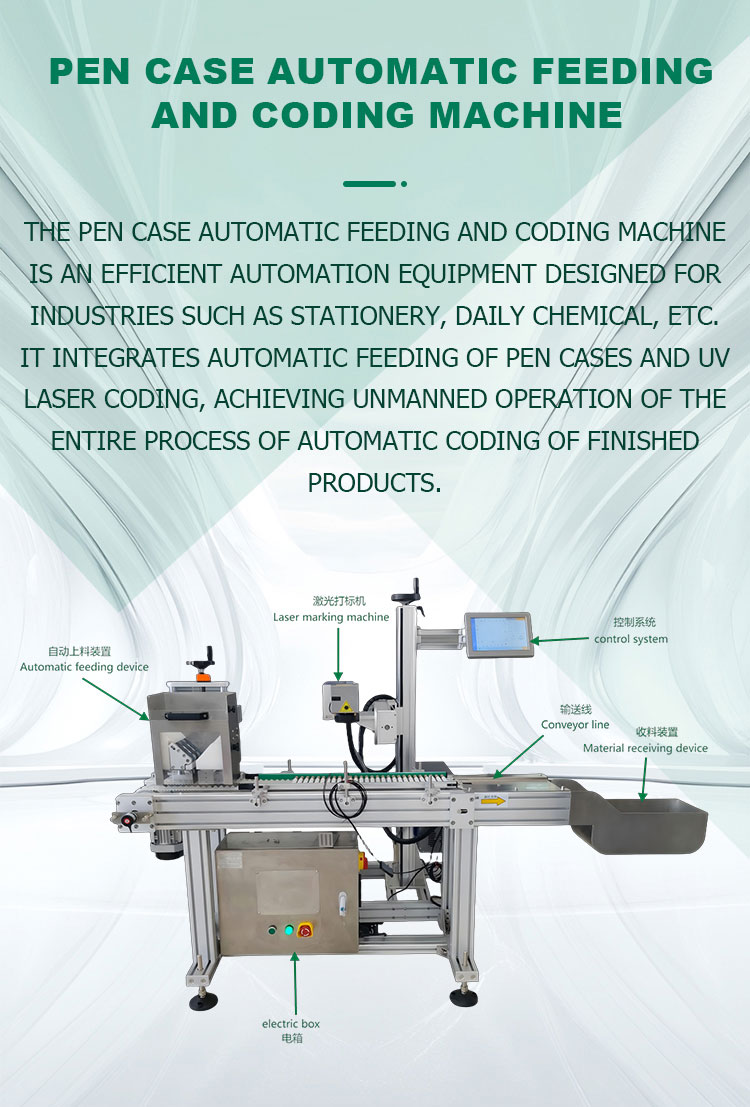

Detailed explanation of the workflow of the equipment

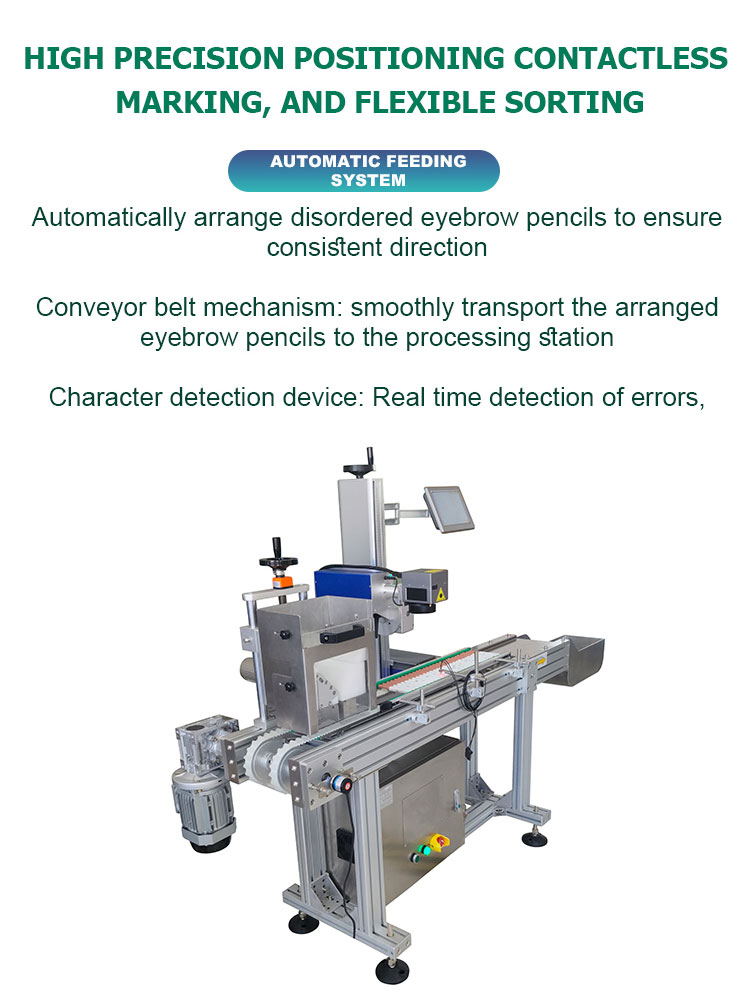

Automatic feeding: This is a critical step of the equipment. Due to the long cylindrical shape of the pen case, it is easy to wrap around, and the following methods are usually used:

Vibration disc feeding: the most commonly used method. The vibrating disc has a spiral track and a filtering mechanism designed according to the shape of the pen case. Through vibration, the randomly stacked pen cases are automatically oriented, arranged neatly, and outputted in sequence.

Hopper+elevator: used for large-scale feeding, cooperating with the material handling mechanism to sort the pen case and send it to the conveyor line.

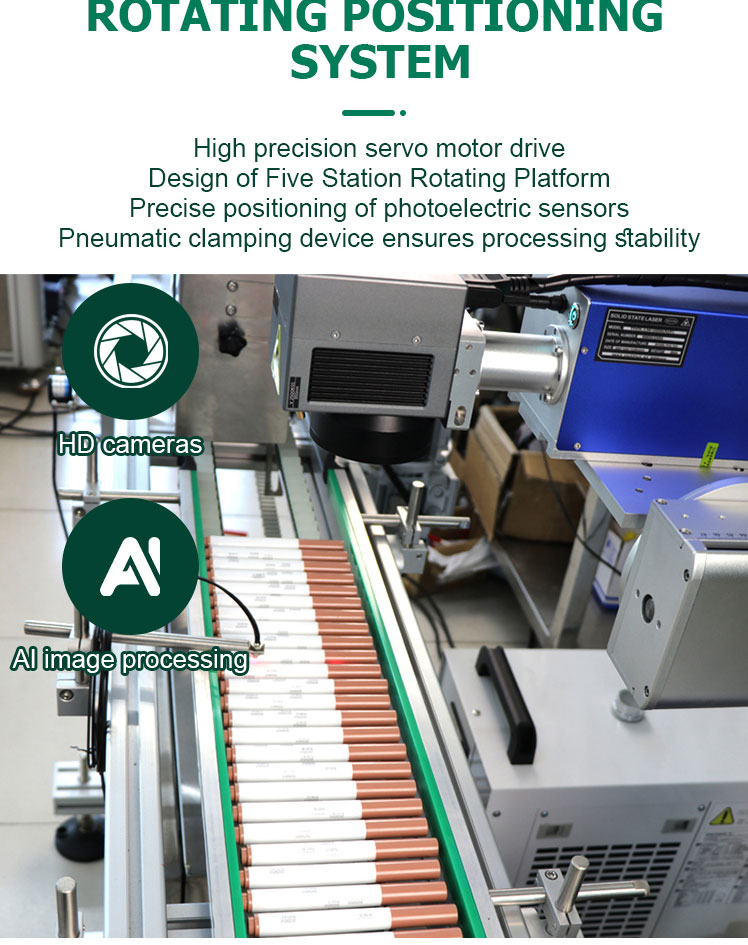

Transport and positioning: The neatly arranged pen cases are transported to the laser marking station. There are usually V-shaped grooves or specialized fixtures to fix the pen case, and may be equipped with a servo rotation mechanism to rotate the pen case during marking, achieving continuous pattern and text carving on the cylindrical surface.

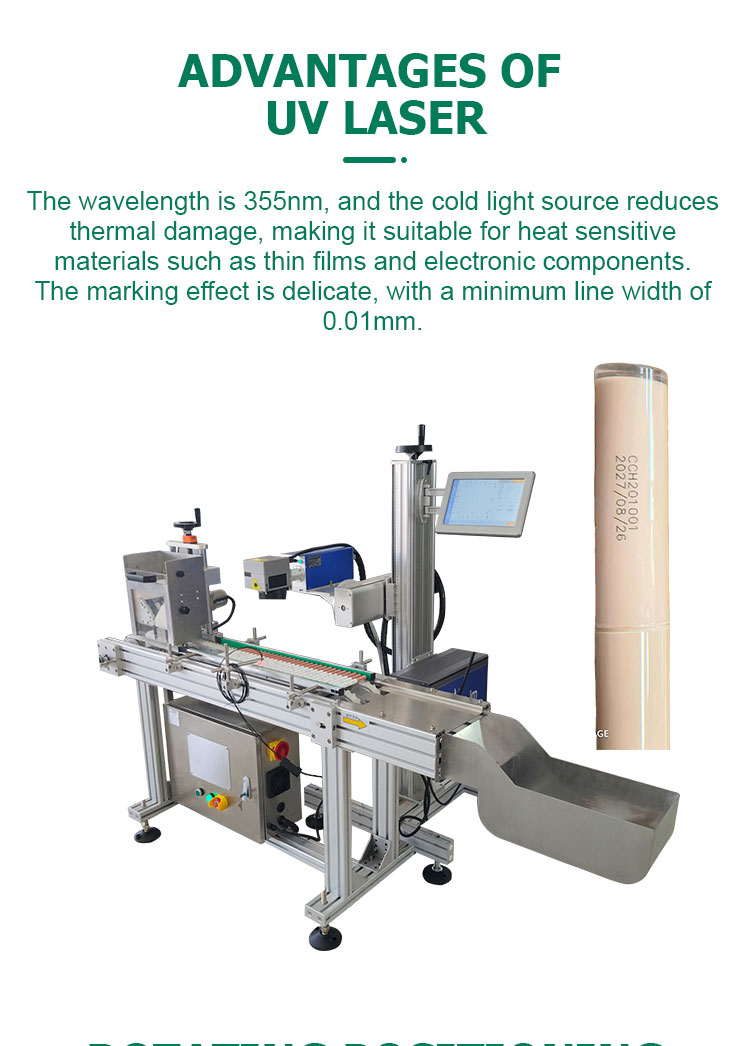

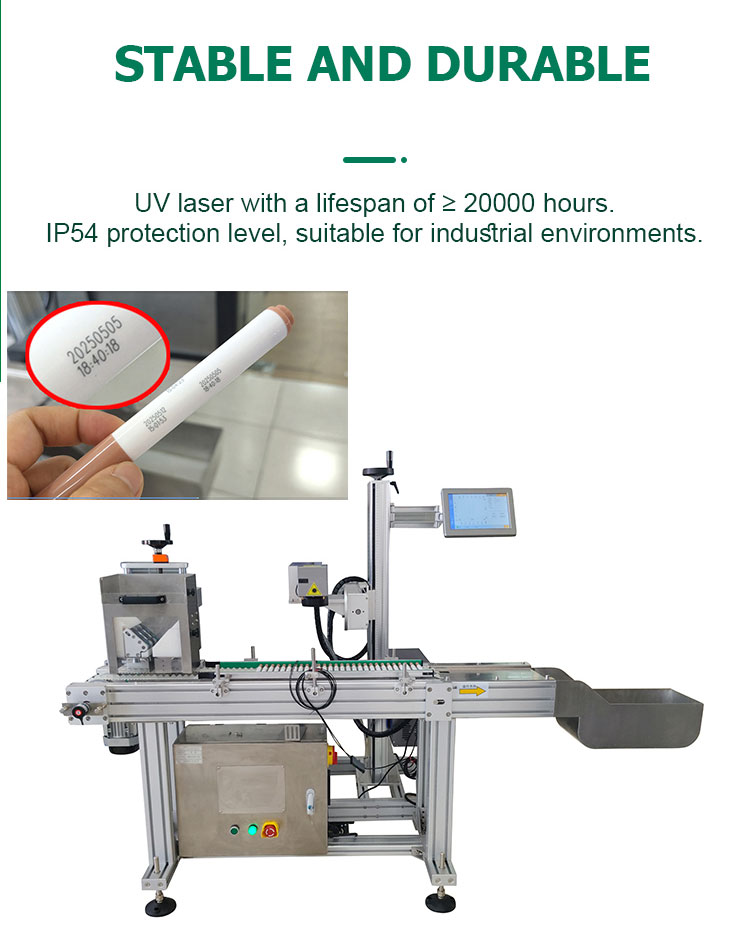

Laser marking:

Fiber laser: suitable for the vast majority of plastic and metal pen cases, with fast marking speed.

UV laser: suitable for heat sensitive plastics (such as certain ABS materials), belonging to "cold processing", with clearer marking effect and no burning sensation at the edges.

The marking content is controlled by computer software and can be easily edited with text, serial numbers, QR codes, vector graphics, etc.

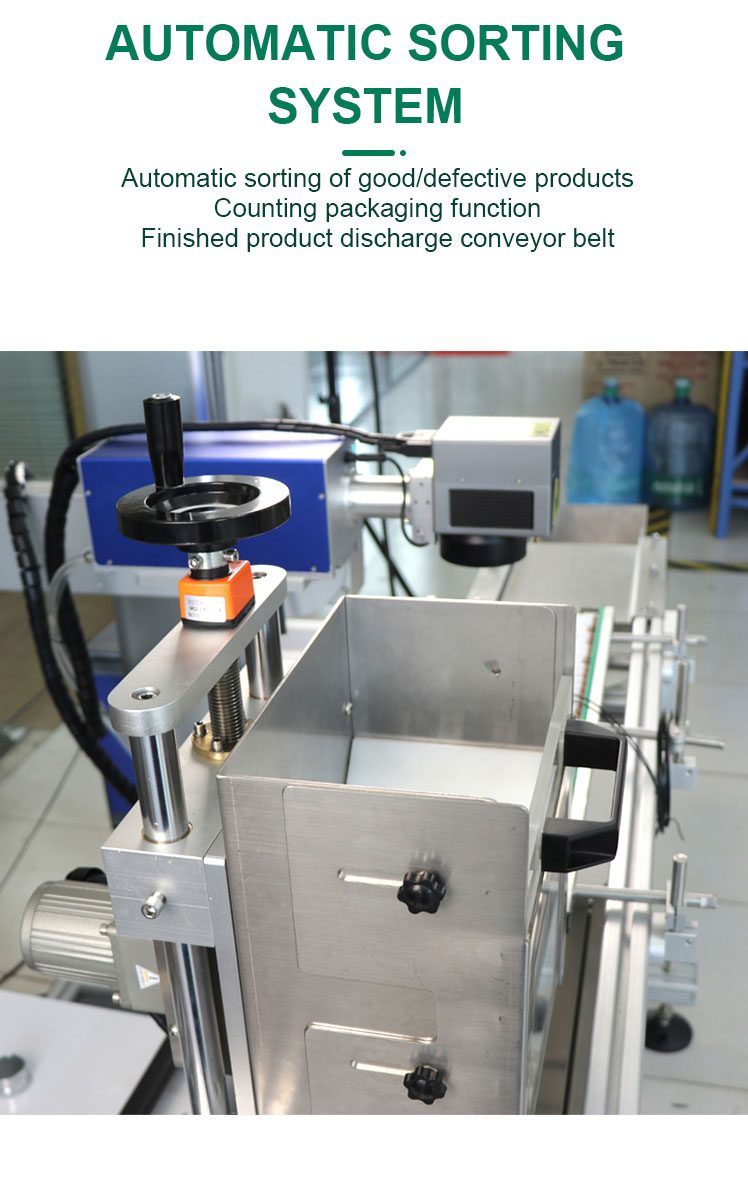

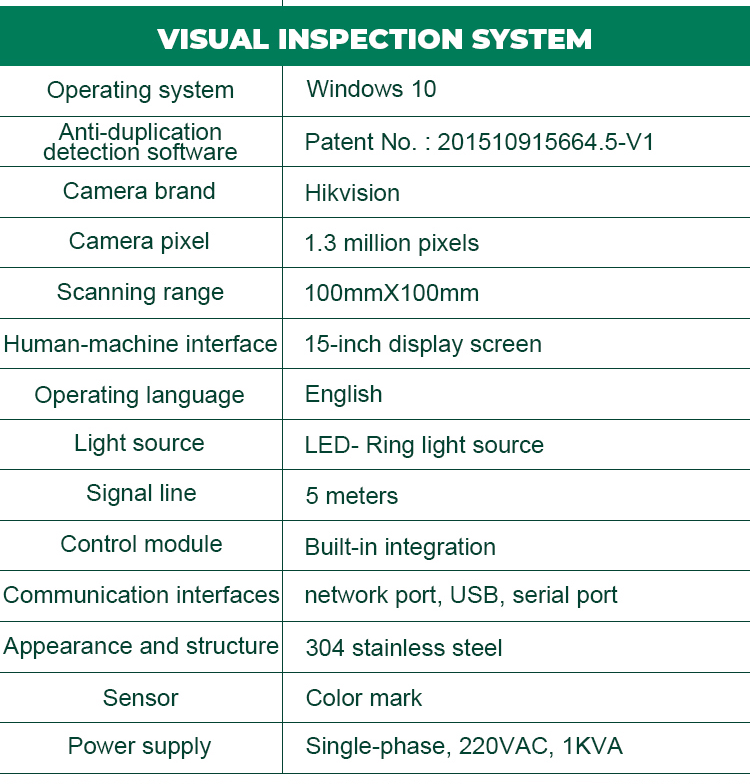

(Optional) Visual inspection: High end integrated equipment will immediately set up a visual inspection station after marking, and the camera will automatically detect the clarity, omission, and correct position of the marked content, and automatically remove defective products.

Automatic cutting: The marked pen case is automatically transported to the collection box or flows into the next assembly process (such as installing pen refills and caps).

ENQUIRYPen case automatic feeding and printing integrated equipment

Chinese

Chinese English

English