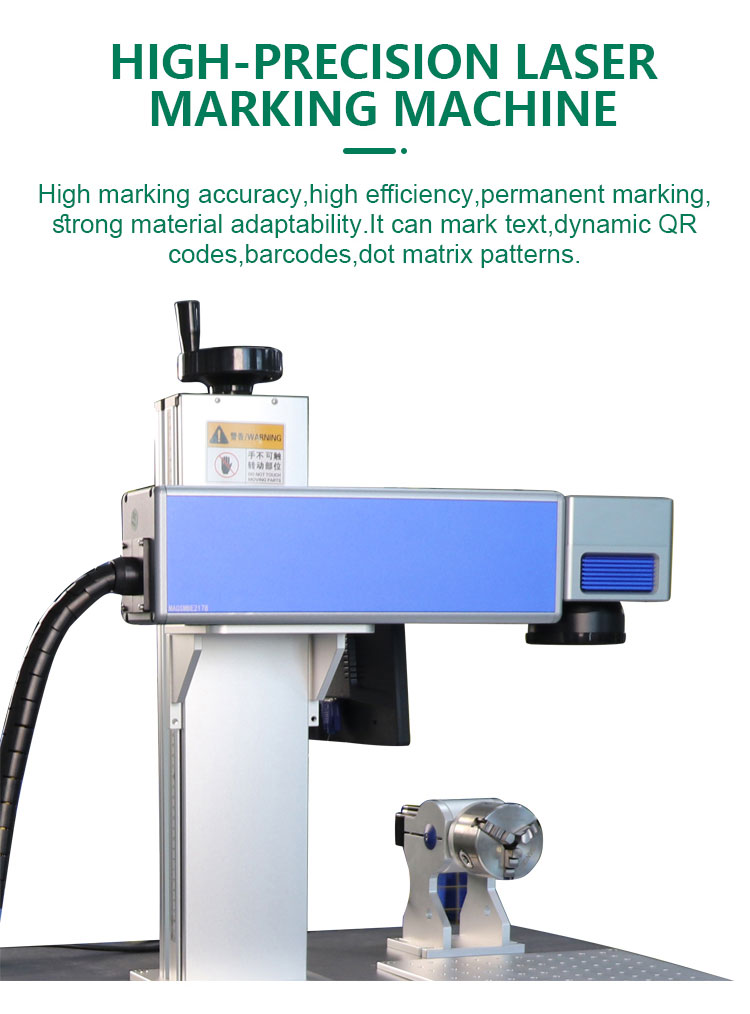

- Product description

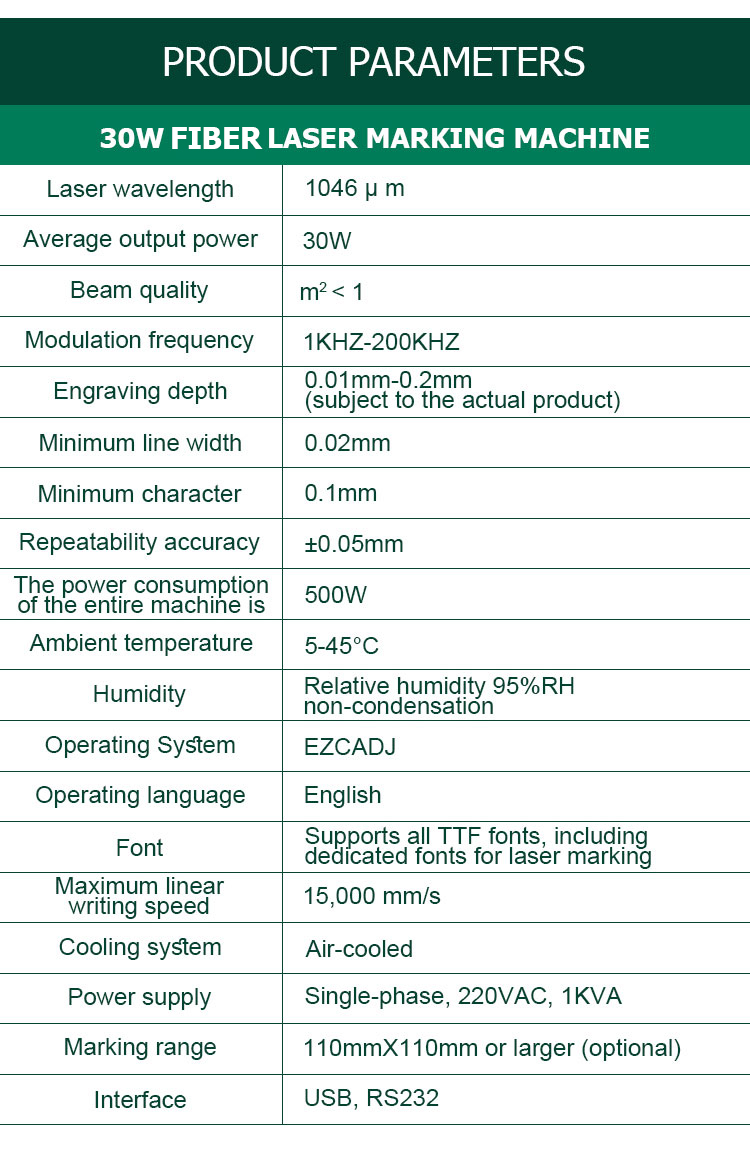

- Technical parameter

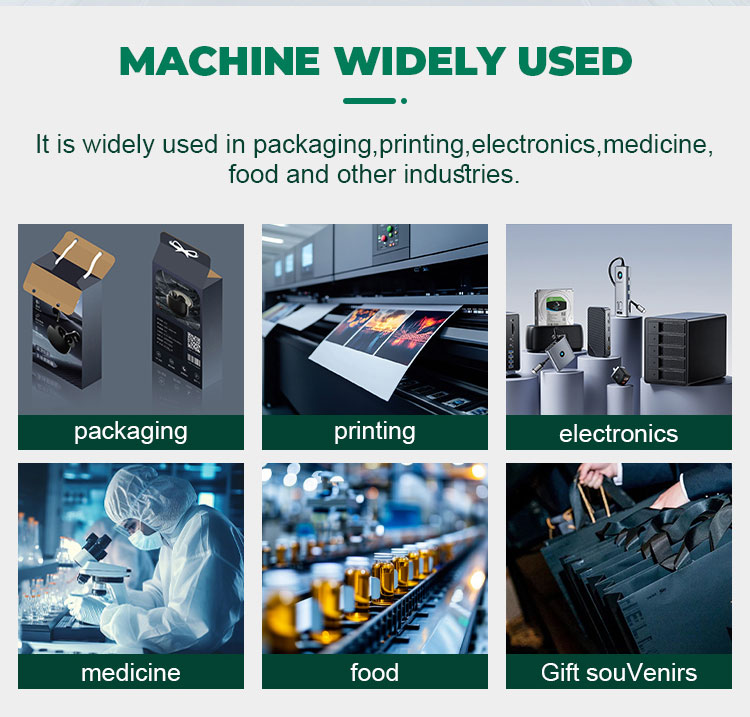

- Application field

- Sample display

1. Electronic and semiconductor industry (high-precision demand)

This is one of the fields with the highest requirements for marking accuracy, speed, and clarity.

Specific application:

Chip marking: Engrave the model, batch number, and QR code on the chip, with small and absolutely clear characters.

PCB board marking: marking the serial number, QR code LOGO。 Laser marking is stress free and will not damage precision circuits.

Identification of electronic components such as resistors, capacitors, inductors, headphones, etc.

Electrical shell: Brand logo and parameter information on mobile phone shell, keyboard, and home appliance panel.

Technical features: Small format, high-precision galvanometer systems are often used, and ultraviolet laser marking machines (a type of fiber laser) are used for "cold processing" to avoid thermal effects damaging sensitive electronic components.

2. Metal products and hardware tools industry (most widely used)

Fiber lasers have excellent absorption rates for metal materials, making them suitable for applications in this field.

Specific application:

Hardware tools: batch number, specifications, brand logo, such as pliers, wrenches, drills, etc.

Sanitary ware: Trademark and model on stainless steel faucets and showerheads.

Kitchen knives: brand logo, material description (such as "304 STAINLESS STEL").

Metal accessories: specifications and traceability codes on bearings, gears, screws, and rivets.

Technical features: Mainly using laser "hot processing", deep black marks are made through oxidation reaction or concave marks are made through carving, which is wear-resistant and durable.

3. Automotive and Parts Industry (Traceability Requirements)

The automotive industry has mandatory requirements for the traceability of components, and fiber laser marking is the preferred solution.

Specific application:

Engine components: piston, cylinder block numbers and QR codes for full lifecycle traceability.

VIN code: A unique VIN code directly engraved on the body of the vehicle, which serves as the "ID card" of the vehicle.

Component traceability: The DPM code (direct component identification) on brake pads, filters, spark plugs, and other accessories facilitates production and quality control.

Automotive dashboard: icons and text on buttons and decorative strips.

Technical features: The marking depth needs to be deep to ensure that it can still be read in harsh environments (high temperature, friction, oil stains).

4. Medical device and pharmaceutical packaging industry (safety and compliance requirements)

The industry has extremely high requirements for the permanence, non toxicity, and cleanliness of markings.

Specific application:

Surgical instruments: Stainless steel surgical scissors, forceps, knives, etc. with specifications, models, and UDI (Unique Equipment Identification) codes for easy disinfection and traceability.

Medical equipment casing: information labels for devices such as heart rate monitors and ventilators.

Pharmaceutical packaging: batch number, expiration date, and electronic drug supervision code on medication bottles, capsule boards, and syringes.

Technical features: The marking should be smooth and free of burrs to avoid bacterial growth. Usually, medical grade stainless steel dedicated laser marking machines are used to ensure biocompatibility of the markings.

ENQUIRYFiber Laser Marking Machine

Chinese

Chinese English

English