Bottle cap automatic feeding laser coding detection integrated equipment

Product number:

- Product description

- Technical parameter

- Application field

- Sample display

1.Beverage and bottled water industry (core application)

This is the industry with the most extensive application and urgent demand for this device.

Specific applications: mineral water bottle caps, carbonated beverage bottle caps, tea beverage bottle caps, juice bottle caps, etc.

Code content: QR code on the inner wall or top of the bottle cap. This code can be used for:

Promotional activities such as "Another Bottle": The equipment can automatically sort winning and non winning bottle caps (requiring connection to a sorting device).

Traceability and anti-counterfeiting: Consumers can scan the code to check the authenticity and production information of the product.

Marketing drainage: Scan the code to jump to the official account and applet for interactive marketing.

Core values:

Realizing precision marketing: Automated coding greatly promotes the development of promotional models such as "open lid rewards".

Cracking down on counterfeiting and shoddy products: One item, one code is an effective anti-counterfeiting measure.

Improve efficiency: Replace traditional inefficient and error prone screen printing and ink coding methods.

2. Alcohol industry

The requirements for quality and brand protection are extremely high.

Specific applications: Baijiu bottle caps, beer bottle caps, red wine bottle caps, yellow rice wine bottle caps.

Code content: Traceability code, anti-counterfeiting code or promotional code inside the bottle cap.

Core values:

Anti smuggling management: By assigning different code segments to different regions, monitor the flow of products.

Brand protection: High end alcoholic beverages have high profits and are a high-risk area for counterfeiting. Laser coding is difficult to tamper with and has good anti-counterfeiting effects.

High end image: Laser coding is clear and permanent, in line with the positioning of high-end products.

3. Seasoning industry

Specific applications: soy sauce bottle caps, vinegar bottle caps, edible oil bottle caps, oyster sauce bottle caps, etc.

Coding content: production date, shelf life, batch number, traceability code.

Core values:

Food safety traceability: Once a quality issue occurs, the problematic batch can be quickly and accurately recalled through the bottle cap code, in compliance with national food safety traceability requirements.

Eliminate date ambiguity or missing information: 100% inspection ensures that the date and other information on each bottle cap are clear and accurate.

4. Pharmaceutical and Health Products Industry

This is the field with the strongest mandatory regulations and the strictest requirements.

Specific applications: pharmaceutical plastic bottle caps, health product bottle caps.

Code content: electronic drug supervision code, UDI (Unique Device Identification) code, batch number, expiration date.

Core values:

Regulatory compliance: Meeting the mandatory requirements of the National Drug Administration Law for electronic supervision of the entire drug process is a necessary condition for product listing.

Patient safety: Ensure medication safety, precise recall, and eliminate counterfeit drugs.

Data integrity: providing accurate and error free data sources for pharmaceutical circulation.

5. Daily chemical and cosmetics industry

Specific applications: skin care bottle caps, shampoo bottle caps, shower gel bottle caps, perfume bottle caps.

Code content: production batch number, expiration date, anti-counterfeiting query code, promotional code.

Core values:

Maintain brand image: Avoid issues such as unclear date printing that may affect brand reputation.

Consumer interaction: Scan the code to learn about product ingredients, use tutorials, and participate in marketing activities.

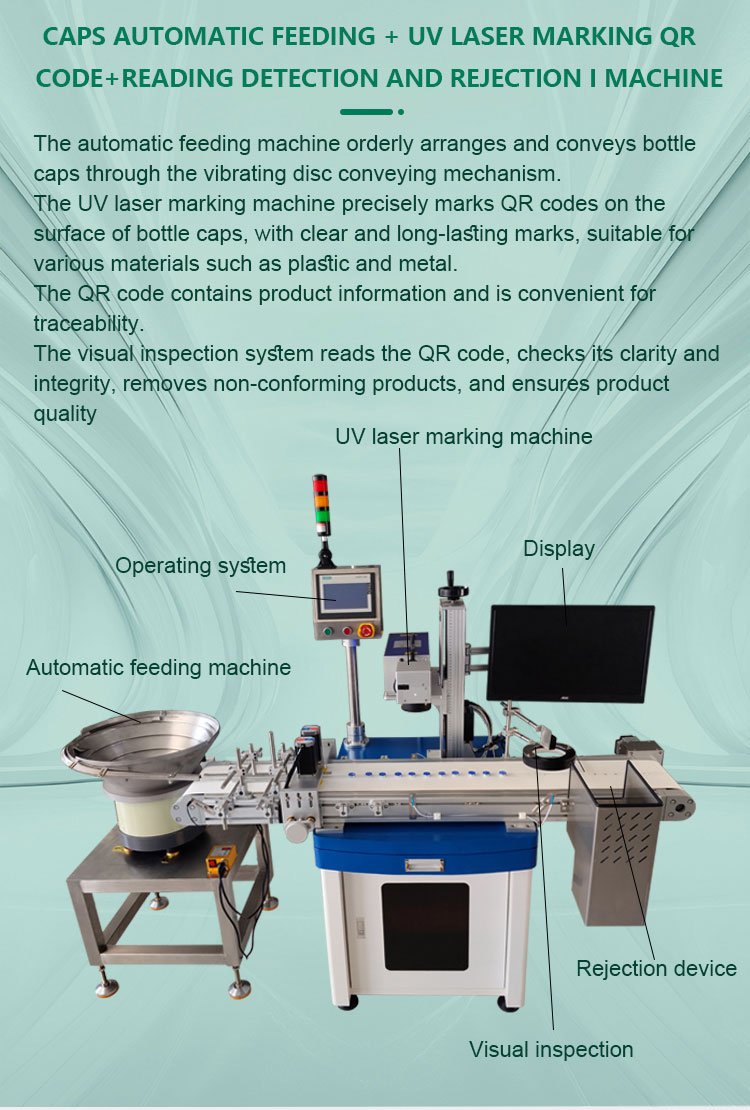

Detailed explanation of the workflow of the equipment

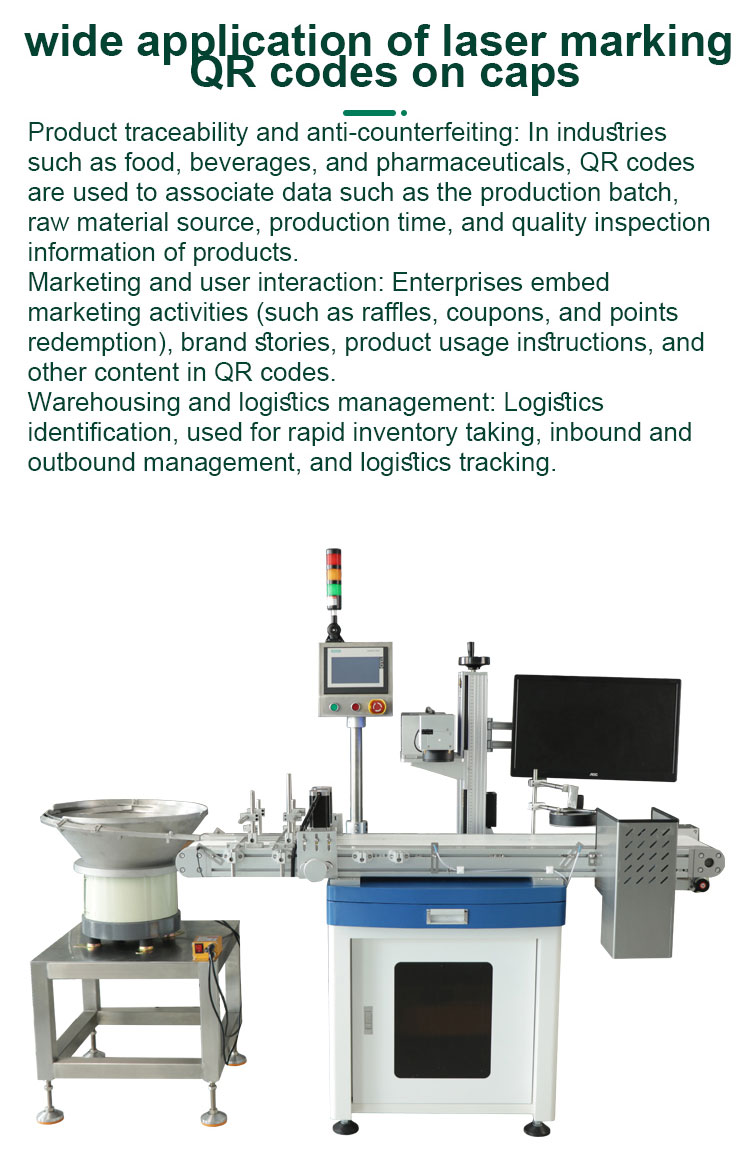

Automatic feeding: The equipment automatically sorts and orderly transports the disorderly stacked bottle caps to the laser marking station through a vibrating disc or a lifting machine+material handling mechanism.

Accurate positioning and clamping: The fixture (usually customized according to the shape of the bottle cap) accurately positions and fixes the bottle cap to ensure consistent marking position.

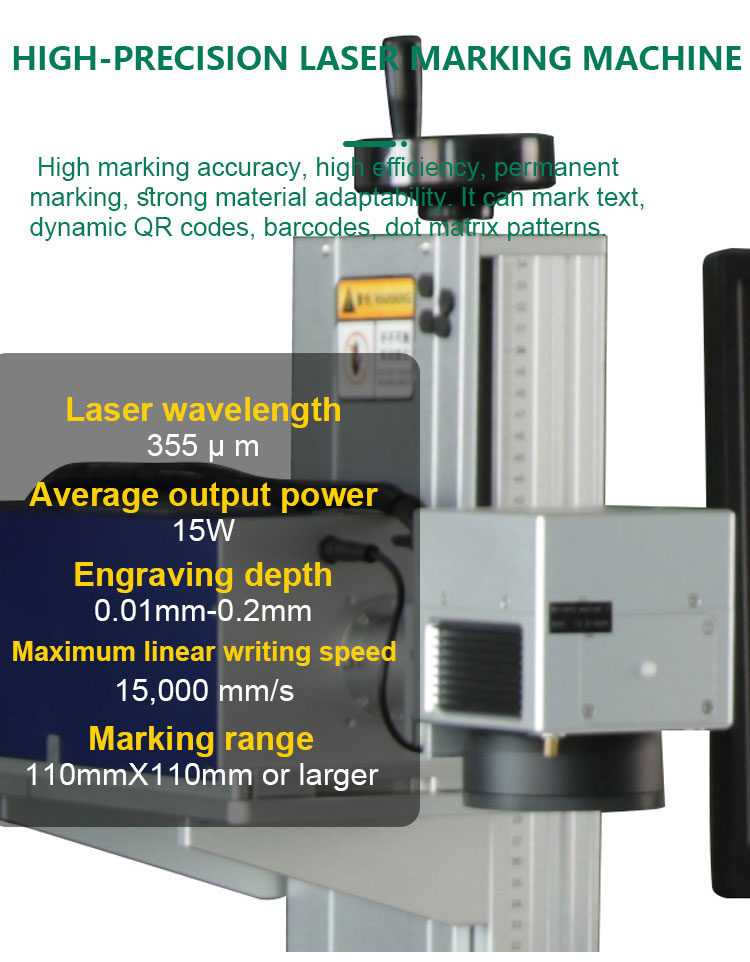

Laser marking: Fiber laser or ultraviolet laser (suitable for sensitive materials) instantly engraves permanent, high contrast QR codes, text or patterns on the inner wall or top of the bottle cap. Compared to inkjet coding, laser coding is more environmentally friendly, permanent, and cannot be erased.

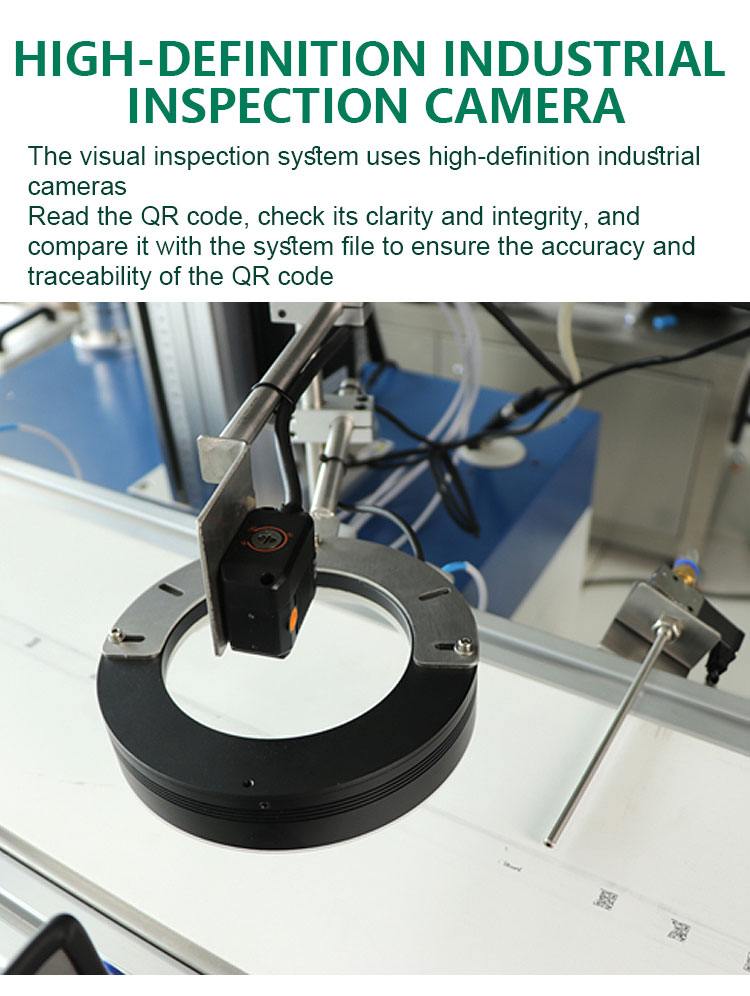

Online visual inspection (core value):

Immediate detection after coding: High speed industrial cameras capture images of the marking area immediately after coding is completed.

AI algorithm judgment: The visual system detects through OCR/OCV algorithm, and the judgment content includes:

Exist: Did you miss the code?

Clarity: Does the QR code level (such as A/B/C level) meet the standard? Is it clear?

Correctness: Is the code content correct? Is it consistent with the data issued by the system?

Position: Is the marking position within the allowable error range?

Data association and exclusion (optional):

Associate the detection results (OK/NG) with the coding data and upload them to the MES system.

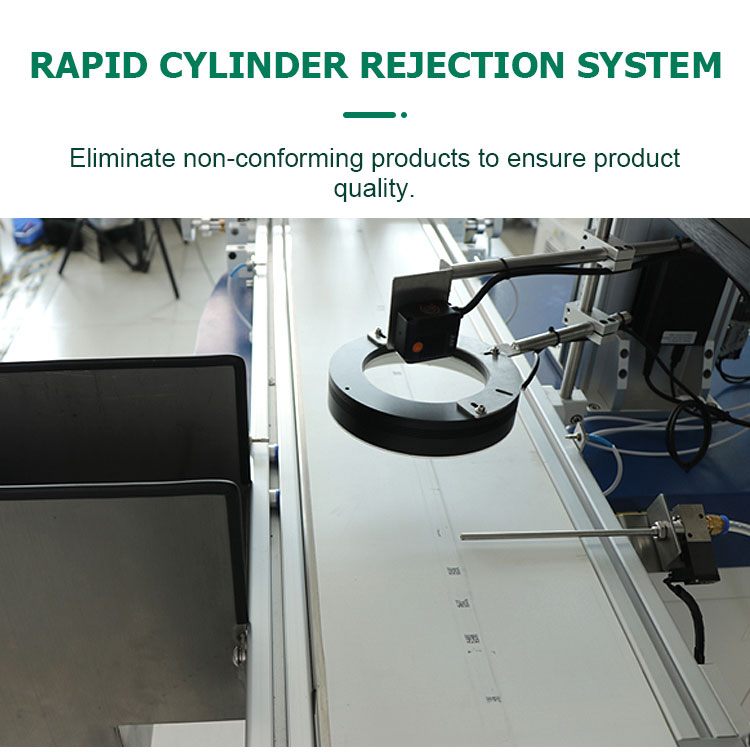

If sorting devices (such as airflow nozzles, robotic arms) are connected, they can automatically remove unqualified bottle caps.

ENQUIRYBottle cap automatic feeding laser coding detection integrated equipment

Chinese

Chinese English

English