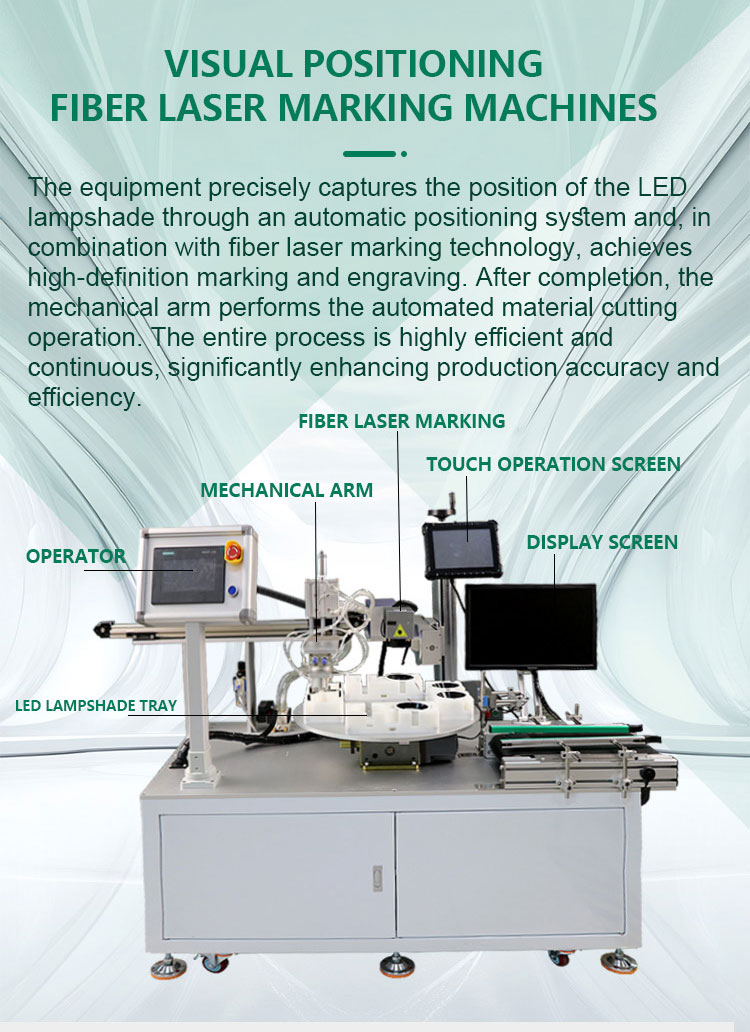

LED light rotating positioning coding+mechanical arm automatic unloading integrated equipment

Product number:

- Product description

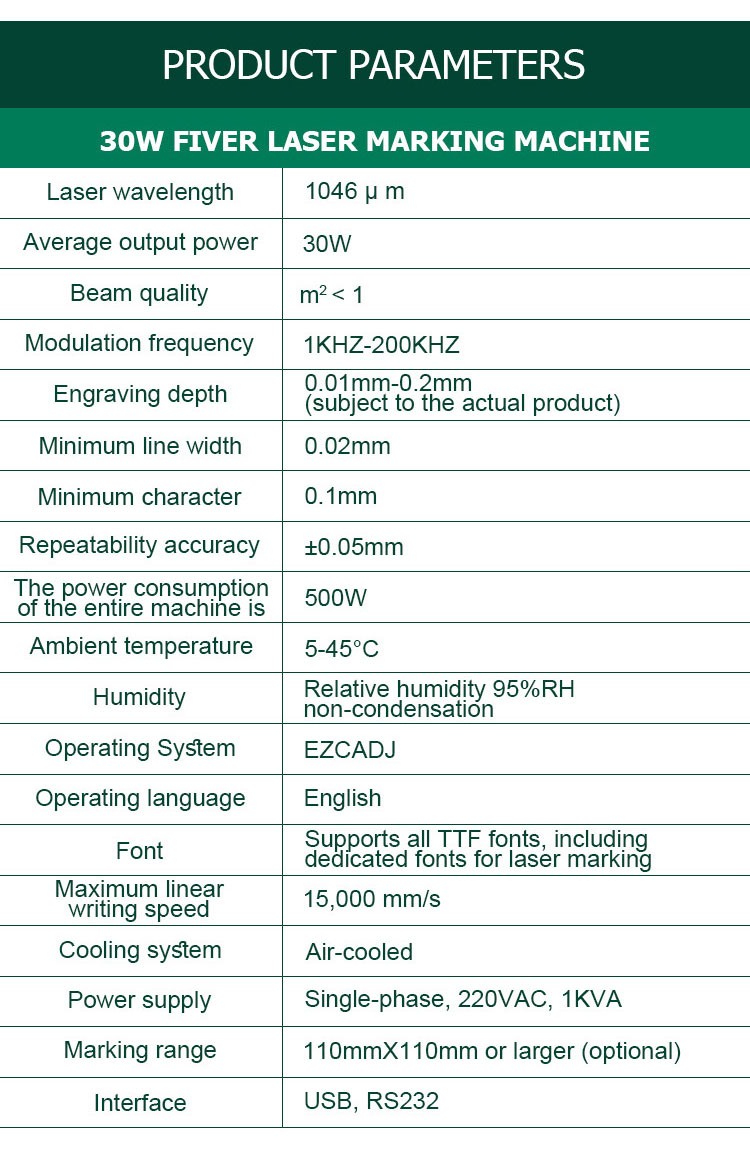

- Technical parameter

- Application field

- Sample display

Workflow:

Rotating positioning: V-shaped blocks or fixtures are used to fix the lamps, and servo motors drive their rotation. Visual cameras capture features on the surface of lighting fixtures to achieve precise positioning and ensure that the QR code is printed in the specified axial and circumferential positions.

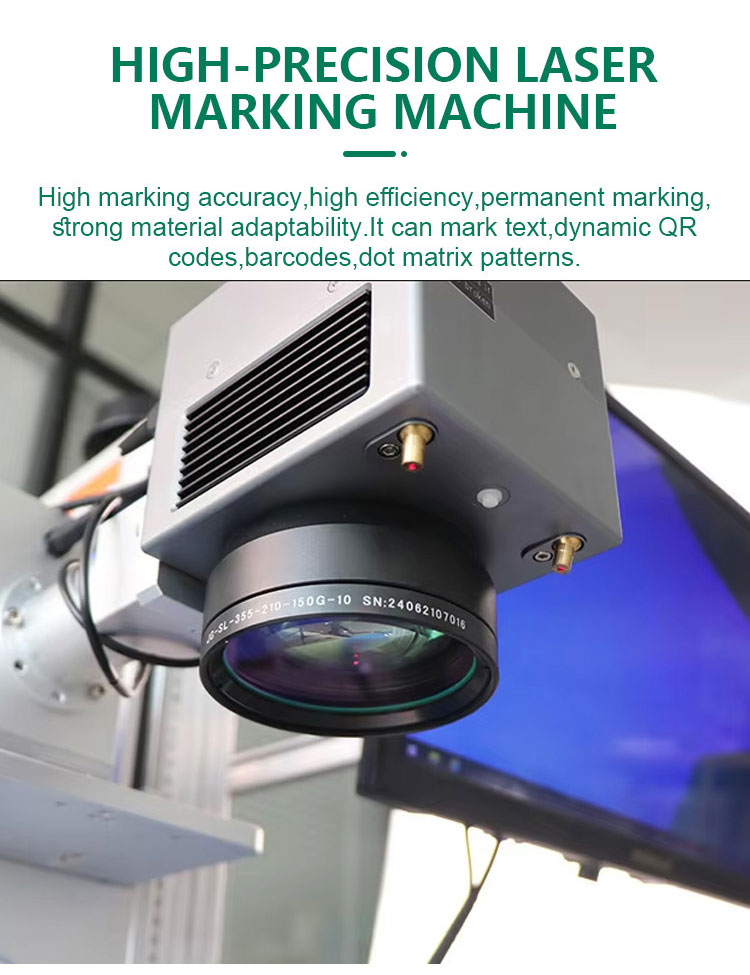

Laser coding: UV laser engraves permanent QR codes (DMR codes) and characters on a positioned cylindrical surface. This code is the "ID card" of the battery, which includes full lifecycle information such as production batch, parameters, date, etc.

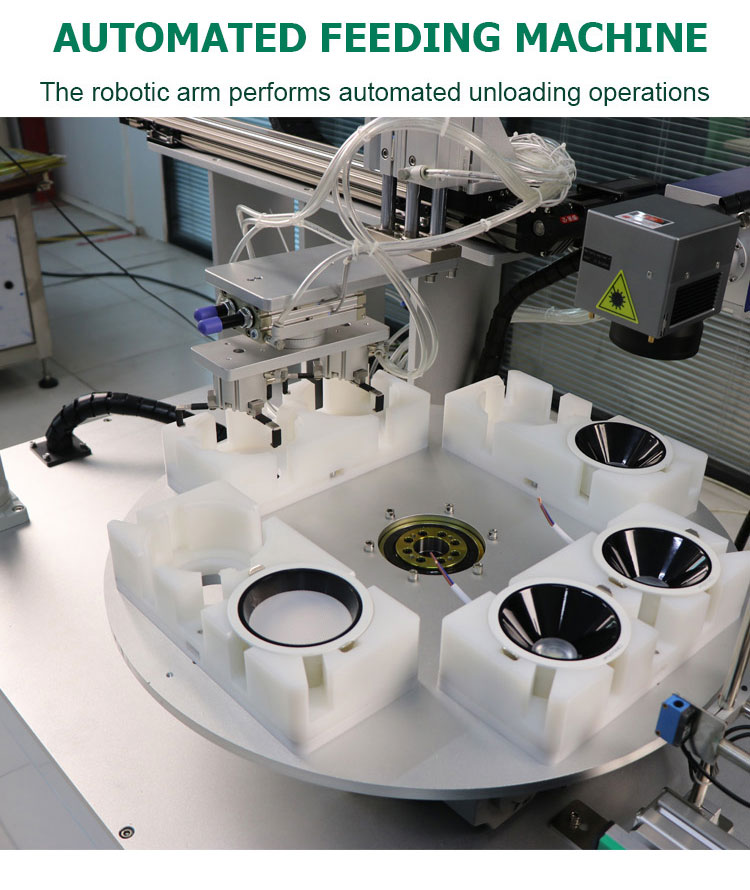

Mechanical arm unloading: Six axis or four axis robot visual positioning accurately grasps the coded lamps, sorts them into different bin picking trays or flows them into the next process based on the reading results (OK/NG).

High precision and consistency: Ensure that each code is in the same position, clear and readable, and easy for subsequent automated equipment scanning.

Improve production efficiency: completely replace manual labor and adapt to the rhythm of high-speed production lines.

Data association: Upload the coding data to the MES system and bind it with the battery performance testing data.

2. Precision Hardware and Automotive Parts Industry

Many automotive components have strict traceability requirements.

Specific applications: Marking of metal cylindrical workpieces such as pistons, bearing rings, shaft parts, valves, cutting tools, drill bits, etc.

Job characteristics: Usually, deep level QR codes or serial numbers are directly engraved on metal surfaces to resist harsh working environments. Mechanical arms need to have high load capacity to handle heavy workpieces.

Core values: quality traceability, anti-counterfeiting, supply chain management. For example, the pistons on the engine have a unique code, which can be accurately recalled if there is a problem.

3. Medical equipment industry

Need to meet UDI (Unique Device Identification) regulatory requirements.

Specific applications: medical supplies such as syringe barrels, medication bottles, test tubes, implant casings, etc.

Job characteristics: High requirements for code clarity and non toxicity, often using medical grade safe cold lasers (such as ultraviolet lasers). The environment requires sterility or cleanliness. The operation of the robotic arm needs to be stable and gentle.

Core values: Meet FDA/NMPA regulations, prevent medical device fraud, and ensure patient safety.

4. Food, beverage, and cosmetics industry (packaging containers)

Mainly used for traceability and anti-counterfeiting of packaging materials.

Specific applications: marking of lipstick tubes, perfume bottle caps, wine bottle bottoms, pop top cans and other packaging containers.

Job characteristics: Usually carried out on high-speed production lines, with high requirements for rhythm. The coding content mostly includes production date, batch number, and traceability source code. Robotic arms are commonly used to put coded containers into packaging boxes (automatic boxing).

Core values: Anti smuggling, consumer anti-counterfeiting inquiry, promotion management, supply chain visualization.

ENQUIRYLED light rotating positioning coding+mechanical arm automatic unloading integrated equipment

Chinese

Chinese English

English