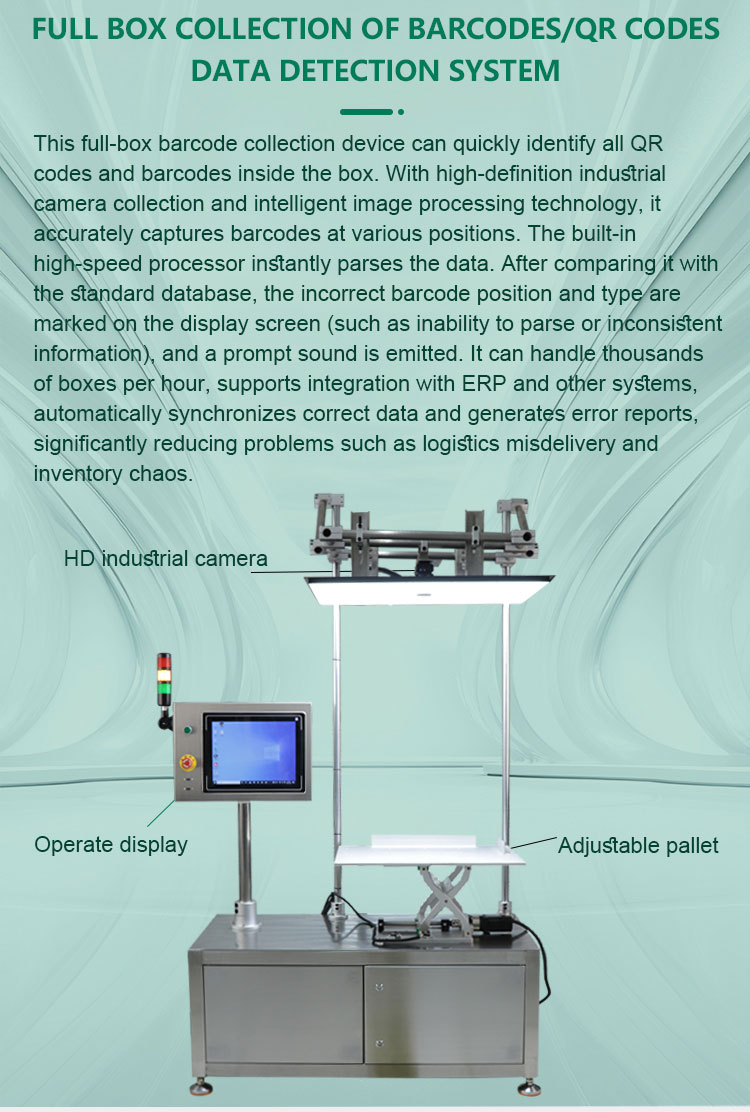

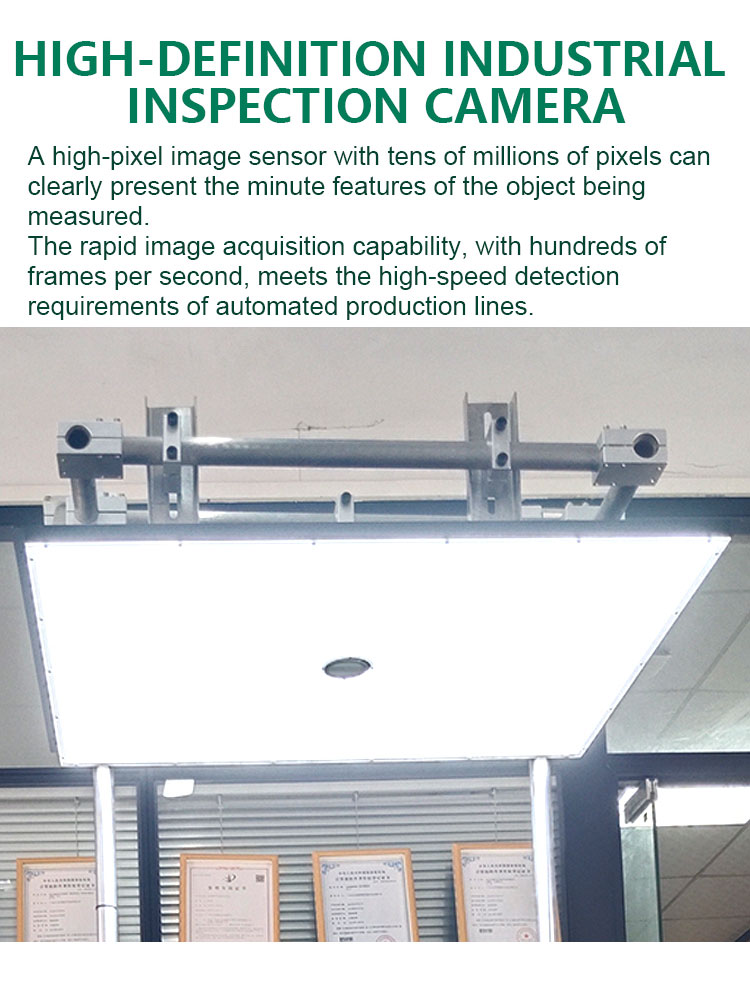

- Product description

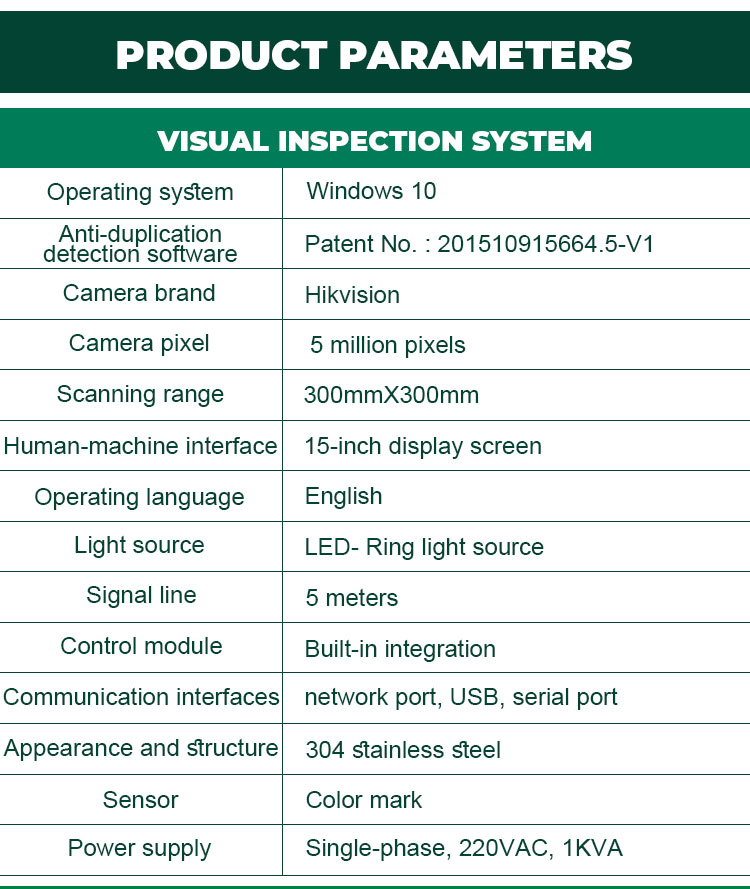

- Technical parameter

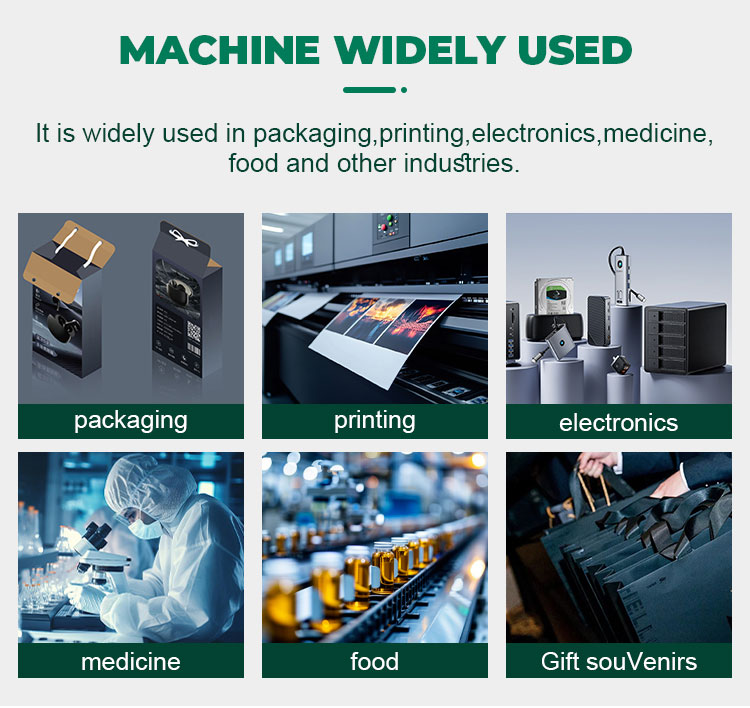

- Application field

- Sample display

1. Pharmaceutical and medical device industry

Mandatory by national regulations, it is necessary to have full traceability capability.

Application Scenario:

Electronic supervision code for drugs: According to national regulations, drugs must be labeled with "one item, one code", with a code on the smallest packaging and an associated box code on the entire box. When entering and exiting the warehouse, the full box code must be scanned for data upload to the national platform.

UDI (Unique Identification of Medical Devices): Similar to drugs, medical devices also require full box unit traceability management.

Core values: Meet the mandatory requirements of regulations such as the Drug Administration Law, achieve precise recalls, combat counterfeit and inferior drugs, and ensure public health and safety.

2. Manufacturing and automotive industries

Used for in plant logistics and supply chain management.

Application Scenario:

In factory material flow: In large manufacturing enterprises (such as automobile OEMs), components are usually distributed to the production line in boxes or material containers. Scanning the full box code can confirm whether the material type and quantity are correct, and trigger the settlement process.

Supplier management: Require suppliers to paste box codes according to standards during delivery to facilitate receipt and information integration.

Core values: Achieving Lean Production (JIT/JIS), precise material distribution, reducing inventory at the production line, and improving production efficiency.

Main forms and technologies of equipment

Handheld data collector: high flexibility, suitable for scenarios such as receiving, inventory, and warehouse transfer.

Fixed industrial scanner: installed on conveyor belts, door frames, and forklifts, used for automated assembly lines without manual intervention.

RFID channel door/reader: batch, long-distance, non-contact reading of RFID tags on the entire box, with the highest efficiency, suitable for high-speed inbound and outbound scenarios.

Visual Recognition System (DWS): This is a more advanced integrated system that can not only scan codes, but also automatically measure the size and weight of the entire box through sensors such as 3D cameras, achieving the integration of scanning, weighing, and measurement, and calculating logistics costs.

ENQUIRYFull box data collection equipment

Chinese

Chinese English

English