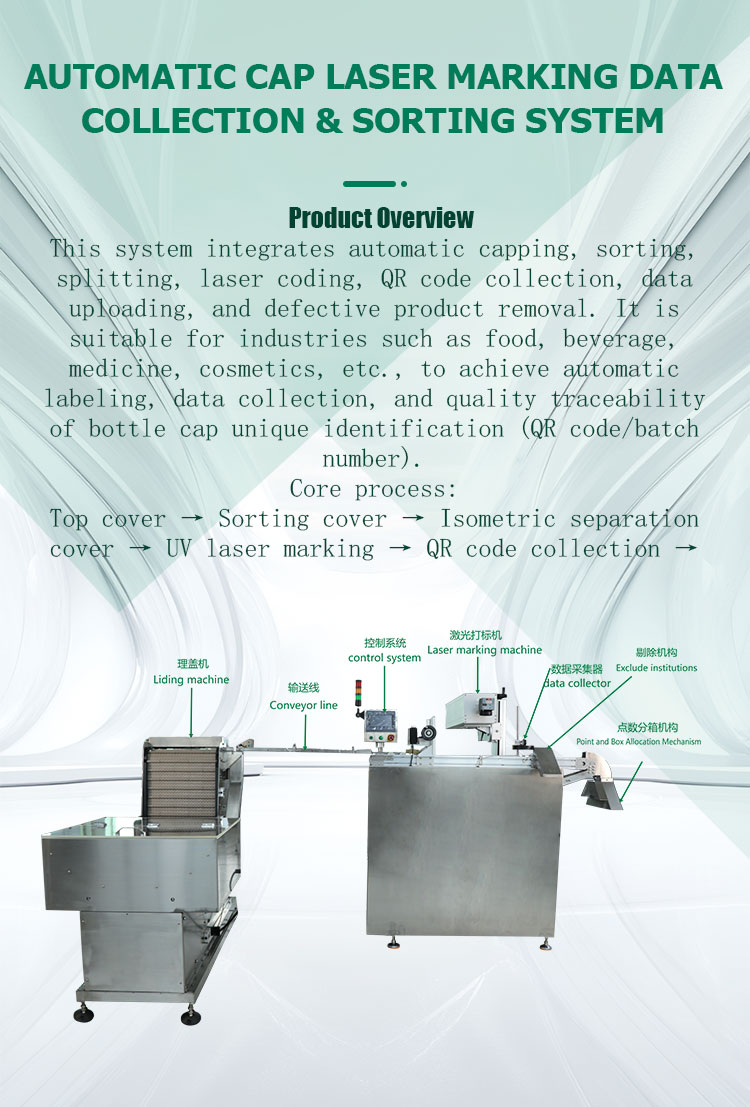

Vibration feeder Material: stainless steel; Disk diameter: 400mm Control mode: FM voltage controller, SDVC31; Coding conveyor line 1. The total length of the conveyor belt is 3 meters, the width is 300mm, it is a rubber belt with baffles on both sides; 2. Variable frequency power mode, adjustable speed from 5-30 meters; 3. All aluminum profile structure; 6. The overall design is reasonable, ergonomic, sturdy and durable;

Product number:

- Product description

- Technical parameter

- Application field

- Sample display

1. Beverage and alcoholic beverage industry

This is the most mainstream and widely used industry for this device.

Functional application:

Internal code assignment and association of bottle caps: Print a unique QR code or digital code on the inner wall of the bottle cap, and associate it with the bottle body and outer box code to achieve full traceability from "bottle box stack".

Marketing and anti-counterfeiting: Consumers can participate in promotional activities such as "another bottle", point redemption, and lucky draws by scanning the code inside the bottle cap. Meanwhile, one item, one code is an effective anti-counterfeiting measure.

Production line sorting: According to different promotional activities (such as "winning" and "not winning"), the equipment automatically recognizes and controls the mechanical arm or airflow to sort the bottle caps to different channels, achieving automated packaging.

Specific cases: promotion and traceability of bottle caps for mineral water, carbonated drinks, tea drinks, beer, Baijiu, red wine, yellow rice wine, etc.

2. Seasoning and Food Industry

The industry has extremely high requirements for food safety traceability.

Functional application:

Production traceability: Record information such as production batch, date, production line, etc. Once a quality problem occurs, it can be quickly and accurately recalled.

Anti smuggling management: By managing code segments in different regions, product flow can be effectively monitored to prevent cross regional sales (smuggling) by distributors.

Taste/variety sorting: For production lines that produce multiple flavors or models of products (such as soy sauce lids and yogurt lids with different flavors), codes can be printed on the lids and automatic sorting can be performed at the end of the packaging to improve efficiency.

Specific cases: Bottle caps/jars for soy sauce, vinegar, edible oil, yogurt, jam, canned goods, and other products.

3. Pharmaceutical and Health Products Industry

This is an industry where traceability is mandatory by regulations, with the highest requirements for equipment accuracy, reliability, and data accuracy.

Functional application:

Electronic supervision of drugs: Under the mandatory requirements of national policies, each box of drugs is uniquely identified and coded to achieve full lifecycle management from production, circulation to patient hands.

Anti counterfeiting and security: Greatly prevent counterfeit drugs from entering the market and ensure the safety of patients' medication.

High precision sorting: Ensure that each package has a correct and readable code, and can automatically remove products that are missed, have unclear codes, or have incorrect data.

Specific cases: Western medicine bottle caps, traditional Chinese medicine bottle caps, health product bottle caps, medicine bottles, aluminum-plastic panels, etc.

4. Cosmetics and personal care products industry

This industry focuses on brand protection, marketing, and consumer interaction.

Functional application:

Anti counterfeiting traceability: crack down on counterfeit and inferior products, and maintain brand image.

Precision marketing: Consumers can scan the code to check the authenticity, ingredients, and usage instructions of the product, and guide it to the online mall, achieving online and offline linkage.

Gift package sorting: Identify and sort different promotional packages or gift packages.

Specific cases: skin care product bottle caps, perfume bottle caps, essence liquid bottle caps, etc.

ENQUIRYVibration feeder Material: stainless steel; Disk diameter: 400mm Control mode: FM voltage controller, SDVC31; Coding conveyor line 1. The total length of the conveyor belt is 3 meters, the width is 300mm, it is a rubber belt with baffles on both sides; 2. Variable frequency power mode, adjustable speed from 5-30 meters; 3. All aluminum profile structure; 6. The overall design is reasonable, ergonomic, sturdy and durable;

Chinese

Chinese English

English