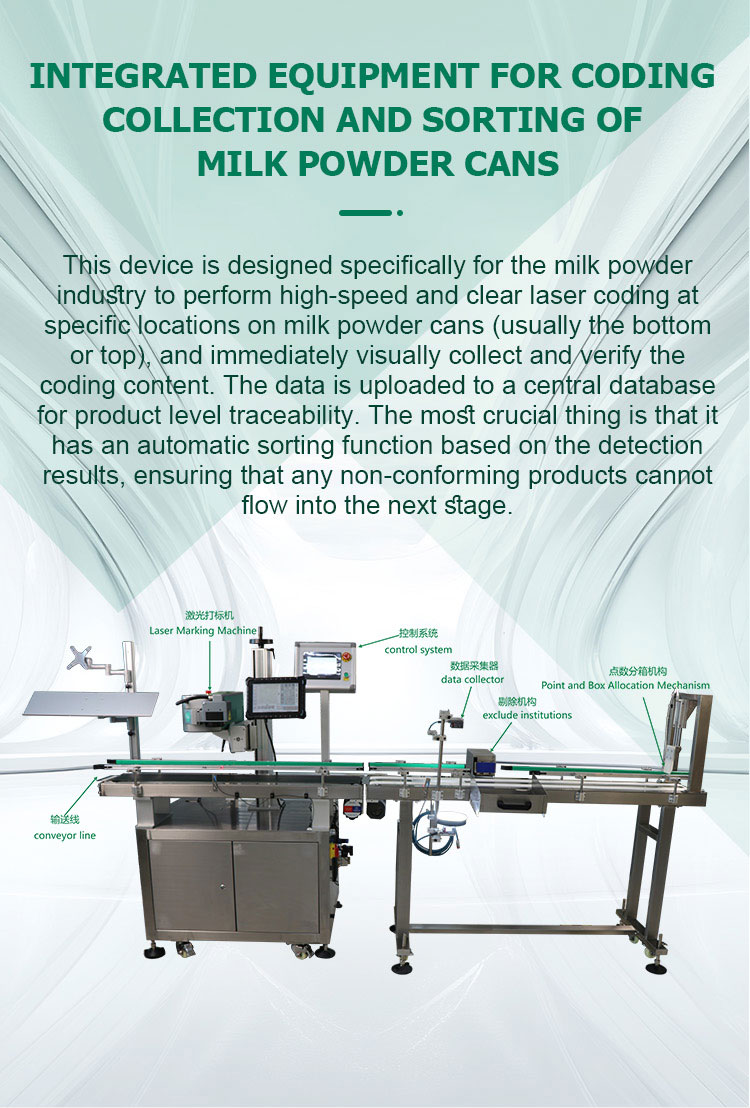

Integrated equipment for coding, collection, and sorting of milk powder cans

Product number:

- Product description

- Technical parameter

- Application field

- Sample display

1. Infant formula milk powder industry (the most important and strict application)

This is the most classic, demanding, and standardized application area of the device. Directly used for the backend of automated production lines for milk powder cans.

Functional application:

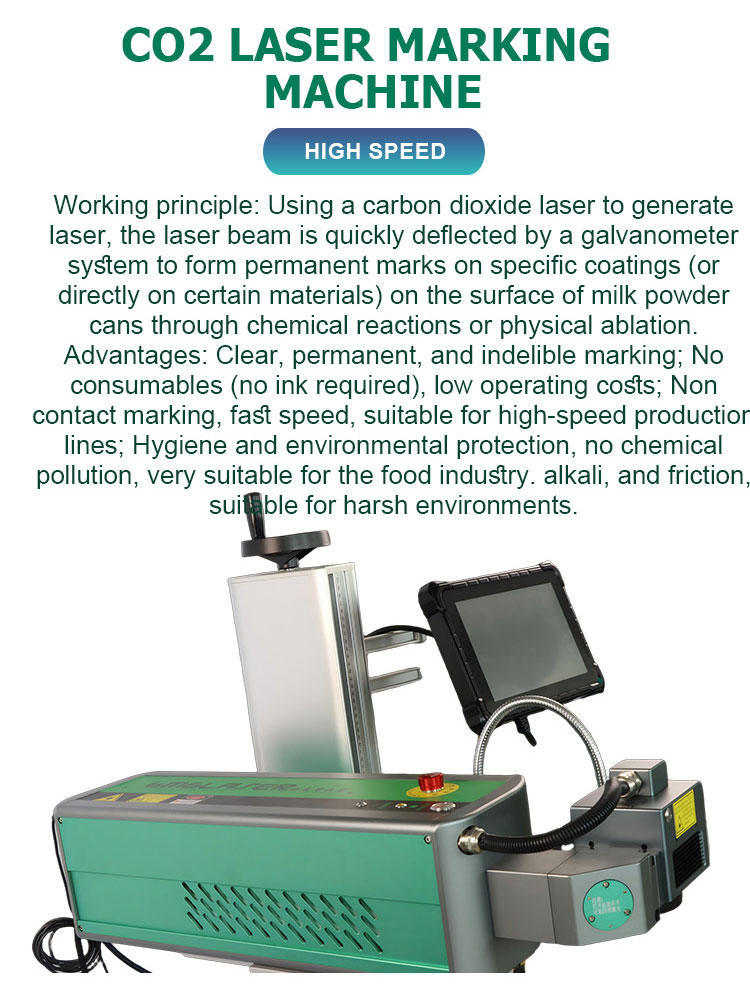

Coding: Laser mark the production date, shelf life, batch number, and unique traceability code on the bottom or top of the milk powder can.

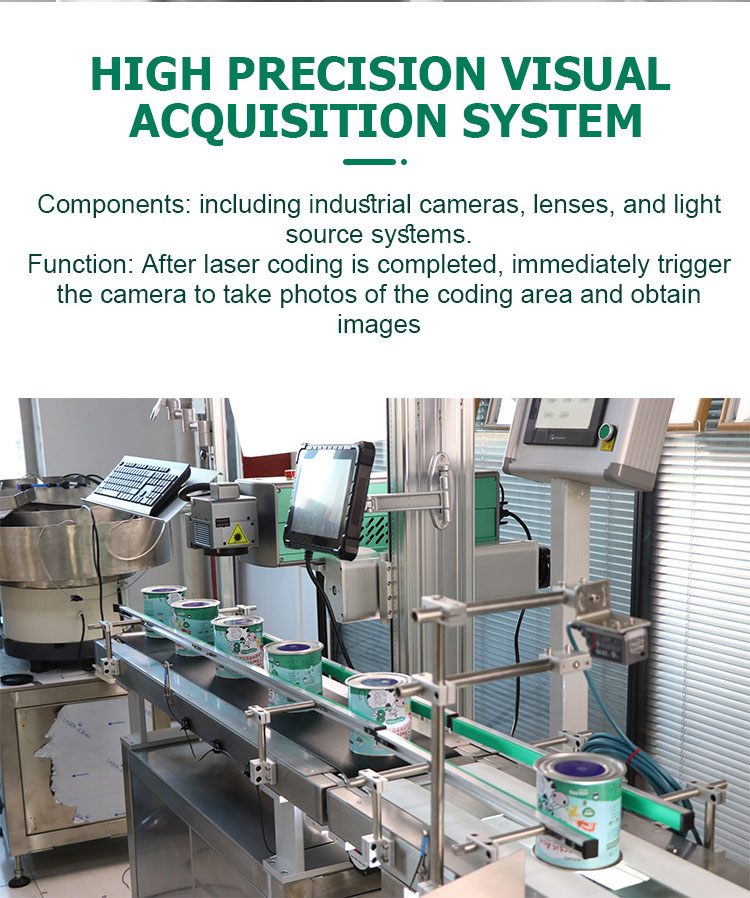

Collection: The high-speed camera immediately reads and verifies the QR code/characters, ensuring that the content is correct and clear to read.

Association: Bind the traceability code with production data (such as production line, shift, milk source batch, inspection data), upload it to the central database, and achieve "one can, one code".

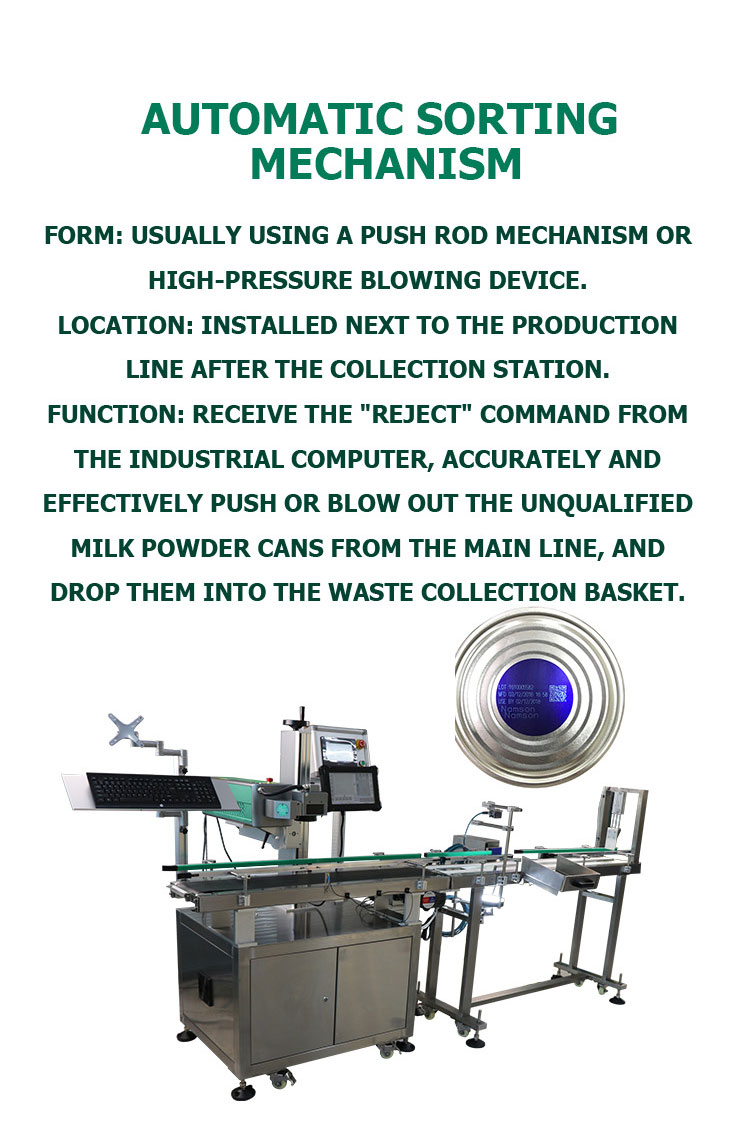

Sorting: Automatically remove all coded defective products (such as no code, blurry, incorrect, or misplaced).

Core values:

Food safety and traceability: Meet the mandatory traceability requirements of the State Administration for Market Regulation for infant formula milk powder. Once a problem occurs, the problematic batch can be accurately and quickly recalled, and even all products produced during a specific time period can be traced.

Quality assurance: Eliminate quality issues such as unclear dates and missing codes from entering the market, avoiding consumer complaints and brand reputation damage.

Anti counterfeiting and anti smuggling: The unique identity code is an effective tool for consumers to check the authenticity and for enterprises to inspect channels for smuggling.

2、 Expand the application industry

The technical solution of this device (coding, collection, association, sorting) is also applicable to other industries that have high requirements for packaging labeling and traceability, especially canned and bottled products.

2. Adult milk powder and nutritional powder industry

Application products: middle-aged and elderly milk powder, women's milk powder, protein powder, soy milk powder, oat powder, etc.

Requirement: Clear production dates, batch traceability, and increasing anti-counterfeiting needs are also required.

3. Health product industry

Application products: various health foods such as canned protein powder, vitamin powder, royal jelly powder, etc.

Requirement: Health products have high value and are a high-risk area for counterfeiting. This device can provide powerful anti-counterfeiting and traceability capabilities, safeguarding consumer rights and corporate interests.

4. Other food industries (canned/bottled)

Application products:

Coffee powder/beans: High end brands need to trace the origin and roasting date.

Seasoning powder: such as pepper powder, chili powder, etc.

High end tea: Canned tea has a strong demand for origin protection and anti-counterfeiting measures.

Requirement: Implement digital management of products and enhance brand image.

5. Pharmaceutical industry (solid powder)

Application products: canned or bottled chemical powder and traditional Chinese medicine powder.

Requirement: The pharmaceutical industry has the strictest requirements for traceability (compliant with GMP and GSP standards). This device can provide a drug level traceability solution, ensuring controllable information throughout the entire chain from raw materials to finished products.

6. Chemical industry (daily chemical/fine chemical)

Application products: canned laundry detergent, care powder (such as talcum powder), and other fine chemical powder products.

Requirement: Batch management and production date identification are required.

ENQUIRYIntegrated equipment for coding, collection, and sorting of milk powder cans

Chinese

Chinese English

English