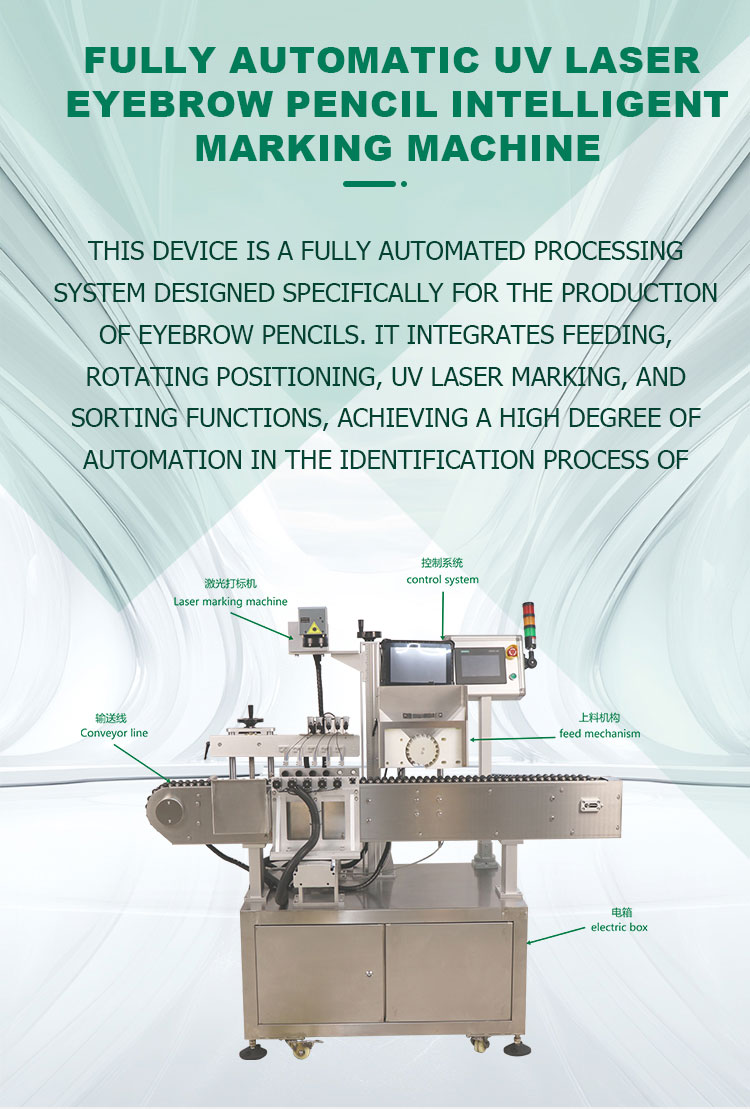

Eyebrow pencil rotation positioning code sorting integrated equipment

Product number:

- Product description

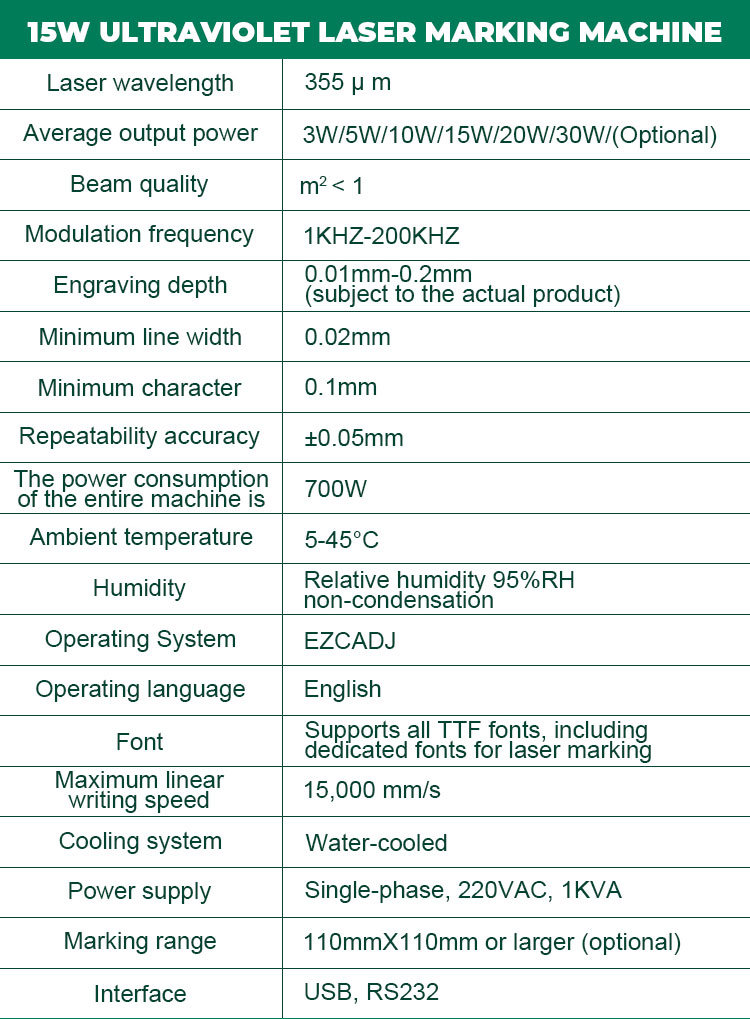

- Technical parameter

- Application field

- Sample display

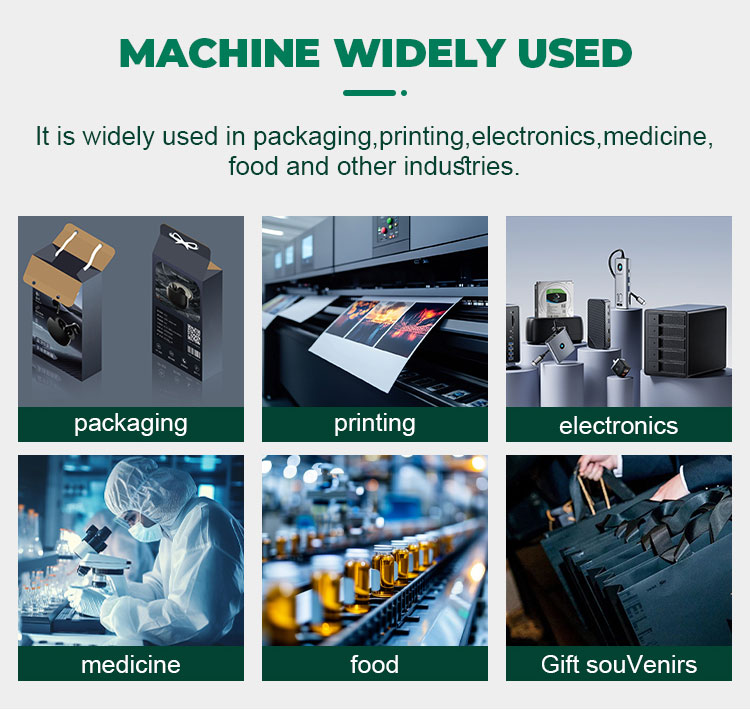

Core application industry

This device is almost exclusively used in the following industries:

1. Cosmetics Industry

This is the most core and primary application area. Specifically applied to:

Production line of eyebrow pencil, eyeliner pencil and lip pencil:

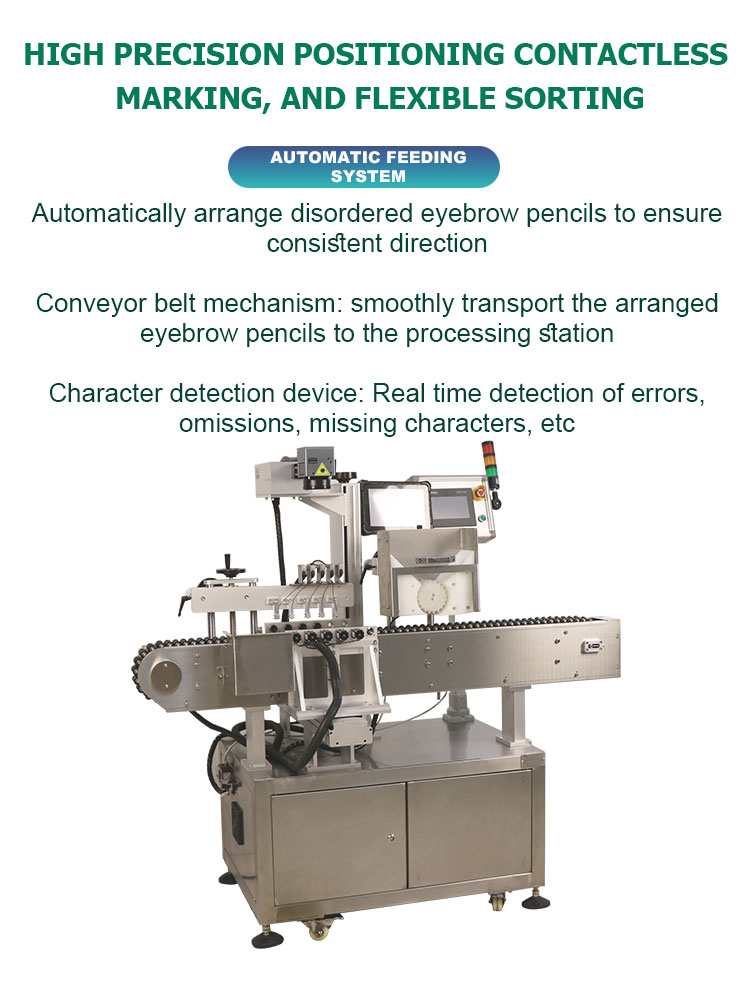

Eyebrow pencil: This is the most typical application object. The device needs to pick up a slender eyebrow pencil, rotate it to find a flat surface aligned with the nozzle, perform laser coding (production date, batch number, traceability code), then immediately detect it, and finally sort it according to its quality.

Eyeliner: similar to the eyebrow pencil in shape and material, it is also difficult to mark and locate the cylindrical surface.

Lipliner/concealer: both belong to pen like cosmetics, with the same production process and demand.

Other cylindrical packaged cosmetics:

Although it is called "eyebrow pencil equipment", its technical principle (rotary positioning) can be adapted to any cylindrical object requiring circumferential coding on the outer wall, such as some lipstick tubes, liquid foundation bottles, essence liquid bottles, etc.

Addressing industry pain points and bringing value

Solving the problem of surface coding:

Pain point: Traditional coding devices are prone to character distortion, blurring, and discontinuity when coding cylindrical objects due to curvature.

Solution: By high-precision rotation positioning, ensure that the linear speed at the time of coding is synchronized with the coding equipment, so that the code printed on the surface can be clear, flat, and not deformed.

Implementing "one item, one code" and precise traceability:

Value: Assign a unique identifier (source code) to each eyebrow pencil and bind production information (time, team, batch). Once a quality issue occurs, it can be quickly and accurately recalled, meeting the requirements of the National Medical Products Administration for traceability of cosmetics.

100% online quality inspection, achieving zero defects before leaving the factory:

Value: Replace manual sampling and conduct a full inspection of the code content (whether it is correct), clarity (whether it is readable), and position (whether it is skewed). Automatically eliminate defective products that are missed, incorrectly printed, pasted, or lightly printed, ensuring that all products entering the packaging process are of good quality and maintaining the brand image.

Improve production efficiency and reduce labor costs:

Value: Integrating coding, testing, and sorting processes into one, fully automated operation, speed that can match front-end filling and packaging lines, significantly reducing the number of operators and avoiding human errors and fatigue issues.

Anti counterfeiting and anti smuggling measures:

Value: Clear and unique traceability code is the foundation of anti-counterfeiting queries. At the same time, code segment management can effectively track product flow and prevent smuggling behavior among distributors.

ENQUIRYEyebrow pencil rotation positioning code sorting integrated equipment

Chinese

Chinese English

English