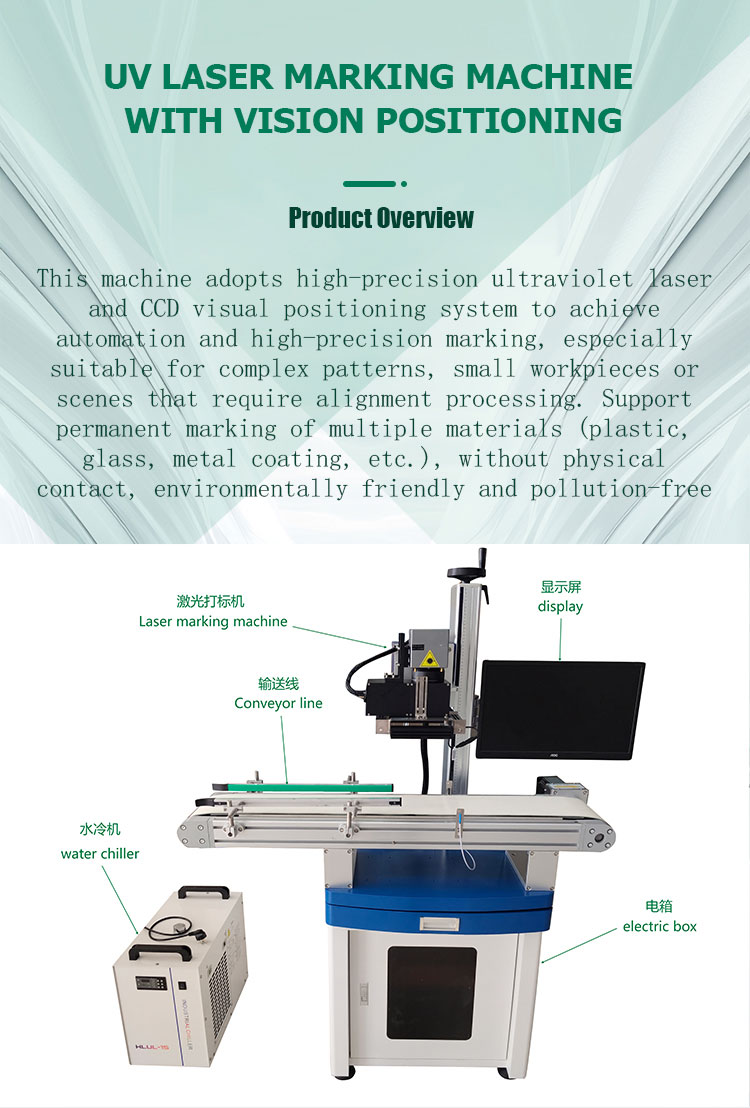

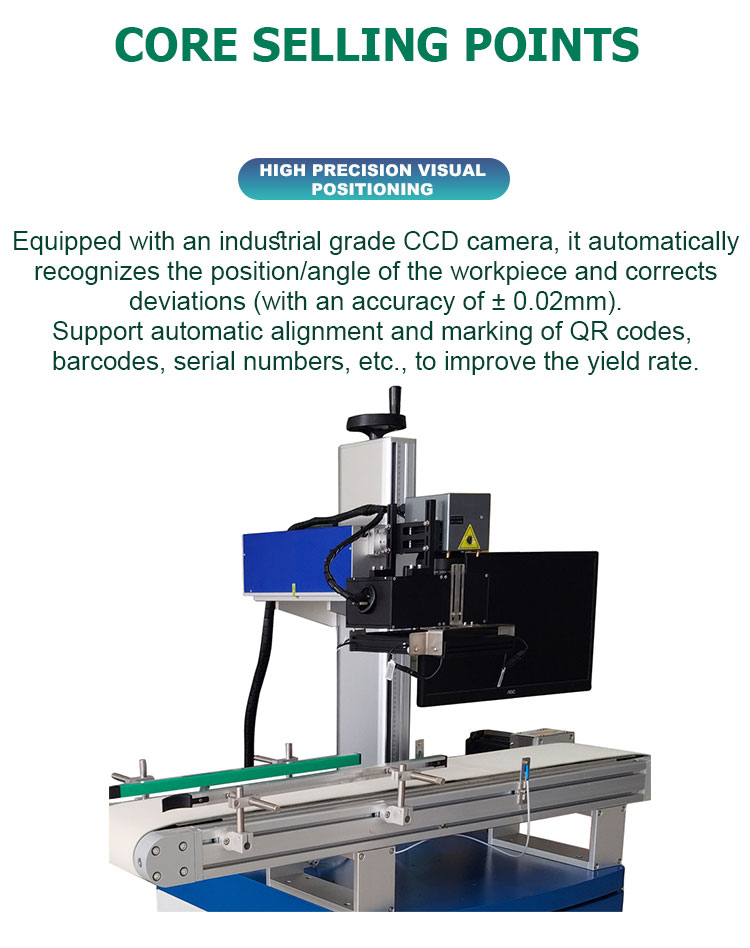

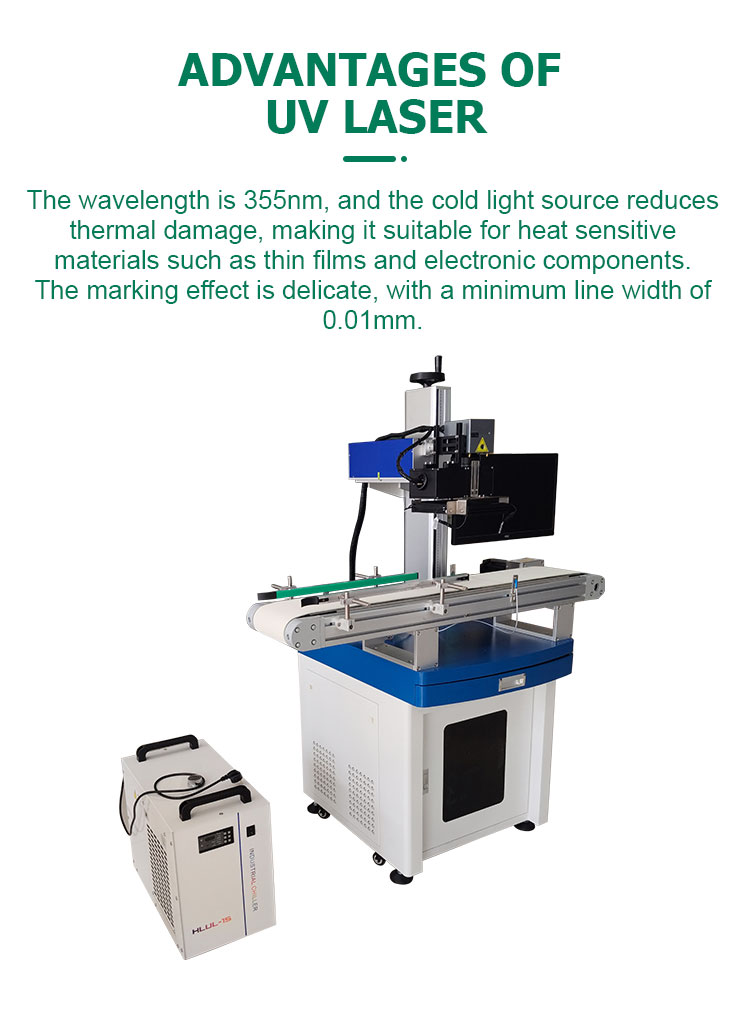

- Product description

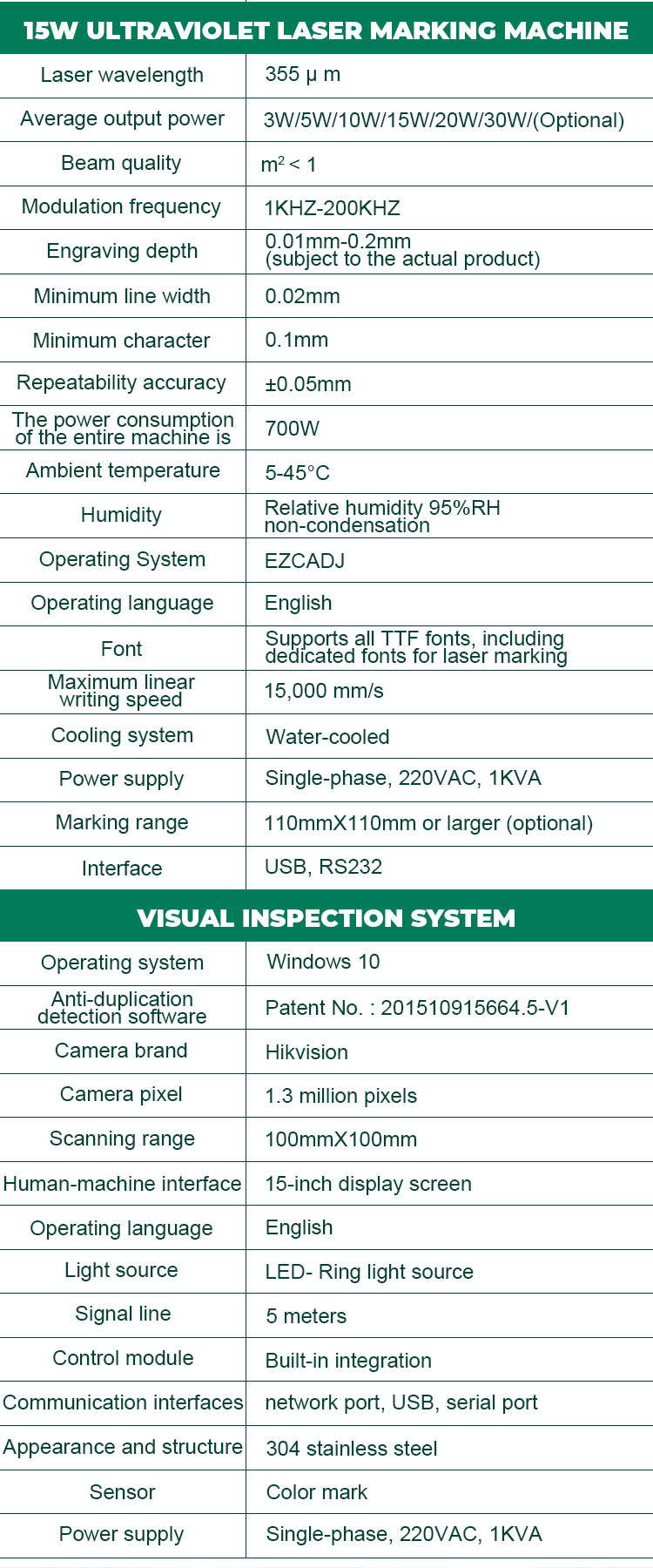

- Technical parameter

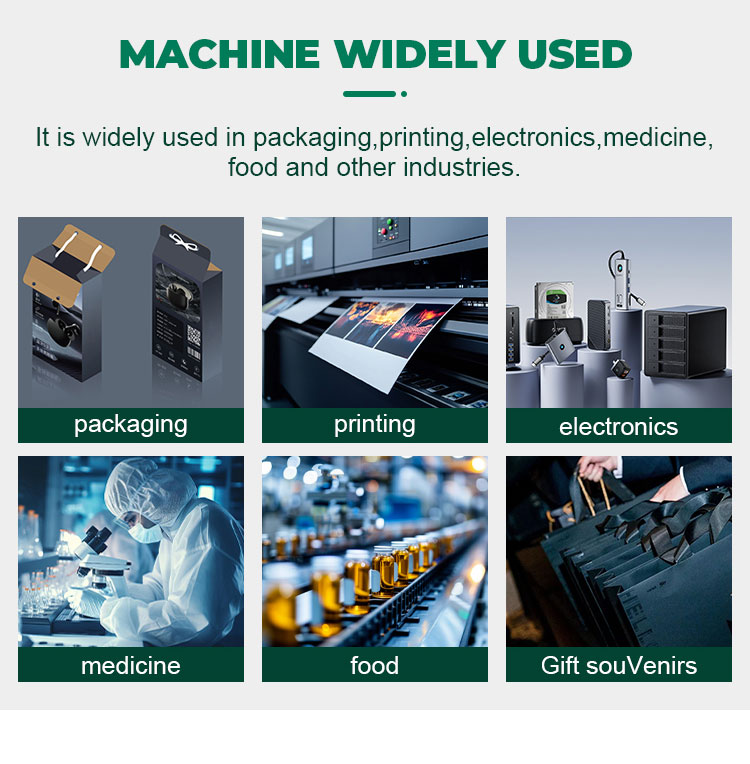

- Application field

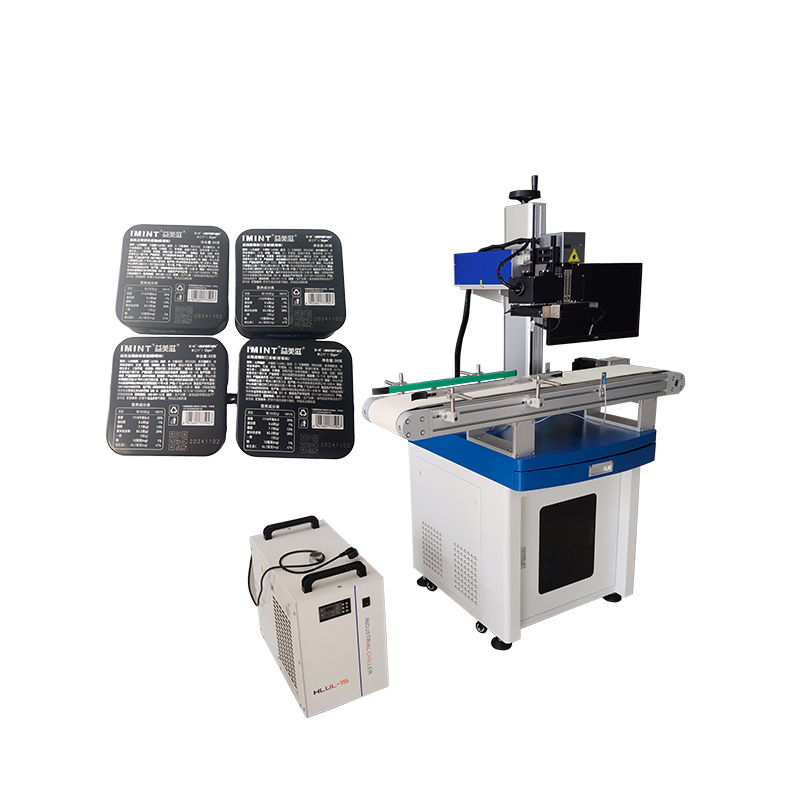

- Sample display

1. Consumer Electronics and Semiconductor Industry

This is the largest and most important application area of visual positioning ultraviolet laser marking machines. Requires extremely high precision and zero thermal impact.

Application Scenario:

PCB/FPC board: Marking QR code (traceability code), serial number LOGO。 The position of the solder pads on the PCB board is very precise, and visual positioning is necessary to ensure that the circuit is not damaged.

Electronic components: Mark the model, parameters, and traceability code on small components such as resistors, capacitors, and IC chips. Components are usually small and require visual positioning to locate the marking position.

Mobile phone components: such as the phone frame, back cover, camera module, SN code, logo and other information on the glass cover. These components are usually treated with anodizing, coating, etc., and UV cold processing does not generate thermal stress that can damage the surface.

Home button and fingerprint module: require extremely high positional accuracy.

2. Medical device and pharmaceutical packaging industry

The industry has mandatory requirements for traceability and cleanliness and accuracy of labeling.

Application Scenario:

Surgical instruments: Label stainless steel or titanium alloy surgical instruments with a unique device identifier (UDI) and serial number. Visual positioning ensures clear and consistent marking on specific surfaces of the instrument.

Medical catheters and implants: marking and tracing information on products such as heart stents and artificial joints. UV cold processing does not alter the biocompatibility of the material.

Medical bottle caps and glass medicine bottles: marked with batch number and expiration date. Visual positioning can overcome the positional changes caused by the threads of the bottle cap, ensuring that each marking is centered on the top of the cap.

Plastic packaging: Labeling on medication bags and infusion bags will not produce a burnt smell and is hygienic and environmentally friendly.

3. Food and cosmetics packaging industry

Mainly used for marking "variable information", requiring the marking to be aesthetically pleasing, clean, and free of chemical contamination.

Application Scenario:

Plastic packaging: Directly label the production date, shelf life, and batch number on PET beverage bottles and HDPE bottles. Replacing traditional ink coding, non-toxic, not easy to peel off, and tamper proof.

Glass bottles and jars: such as logos and date information on wine bottles and cosmetic glass bottles. Visual positioning can adapt to the rotation and placement errors of bottles.

Metal can lid: Mark the inner wall of the can lid and milk powder can lid. UV marking is precise and will not damage the inner anti-corrosion coating.

4. Precision instruments and automotive electronics industry

High requirements are placed on the traceability and durability of parts labeling.

Application Scenario:

Automotive parts: Mark QR codes (part of VIN code) and serial numbers on engine parts, sensors, connectors, etc. for full lifecycle traceability.

Precision gears and bearings: Mark the model and specifications. Visual positioning can ensure accurate alignment on uneven surfaces.

Wiring harness and connectors: Mark the model and polarity to prevent assembly errors.

5. Other high-end applications

Ceramic substrates: such as LED ceramic substrates and ceramic packaging for electronic components.

Flexible materials: Precision drilling and marking on soft materials such as plastic film and leather.

Gifts and luxury goods: Personalized engraving on high-end pens, watches, and other products to enhance product added value.

ENQUIRYVisual positioning UV laser marking machine

Chinese

Chinese English

English