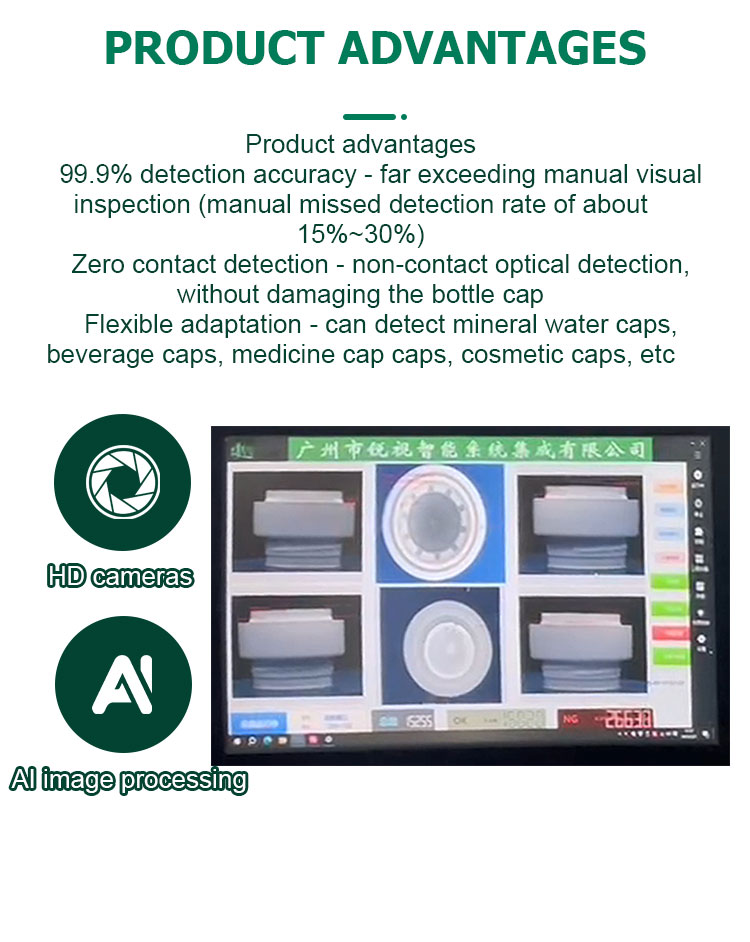

- Product description

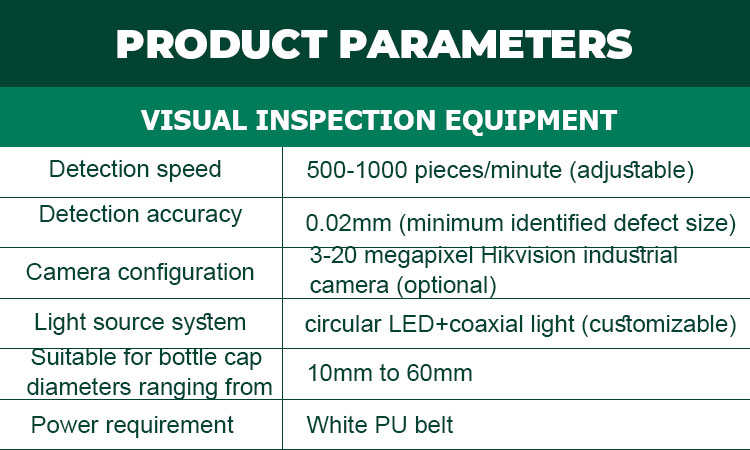

- Technical parameter

- Application field

- Sample display

1、 Core application industry

Beverage Industry

Mineral water/purified water: Check for bottle caps, crooked caps, inadequate sealing, abnormal sealing rings, etc. to prevent water leakage.

Carbonated beverages require extremely high airtightness, and high and crooked caps need to be tested to ensure that the bottle cap can withstand internal pressure.

Tea drinks/fruit juice/functional drinks: In addition to basic testing, character recognition (OCR) is also required for the production date, shelf life, and batch number on the bottle cap to ensure clear and accurate information.

Alcohol industry

Baijiu/wine: The quality of bottle caps (especially metal caps and cork composite caps) directly affects the quality and high-end image of wine. The inspection content includes whether the cover is flat, whether there are scratches, whether the printed pattern is complete, whether the label is skewed, and whether the anti-theft ring is intact.

Beer: Check the quality of the crown cap (beer cap) to ensure sealing and prevent oxidation and air leakage.

Seasoning industry

Soy sauce, vinegar, edible oil: It is crucial to test the sealing of bottle caps to prevent product leakage and spoilage. At the same time, it is necessary to check whether the inner gasket is missing and whether the bottle cap thread is intact.

pharmaceutical industry

Medicine bottles (oral liquid, tablet bottles, etc.): This is one of the areas with the strictest quality requirements. The testing content includes:

Safety ring (anti-theft ring): It is necessary to ensure its integrity and correct connection points, which is an important indicator of whether the drug has been opened.

Sealing: Ensure that the drug is sterile and free from contamination.

Character recognition: Accurately read batch numbers and expiration dates, in compliance with GMP (Good Manufacturing Practice) and traceability requirements.

Cosmetics and personal care products industry

Skincare products, shampoo, shower gel: The appearance of bottle caps directly affects consumers' first impression of the brand. The focus of the inspection is on appearance defects, such as burrs, dirt, color differences, and printing quality (whether the logo and text are clear and correct).

Food industry (other)

Canned food: Check the status of the vacuum safety button (protruding or recessed) to determine if there is any air leakage.

Jam, honey, etc.: Check the sealing and appearance of bottle caps.

ENQUIRYBottle cap visual inspection equipment

Chinese

Chinese English

English