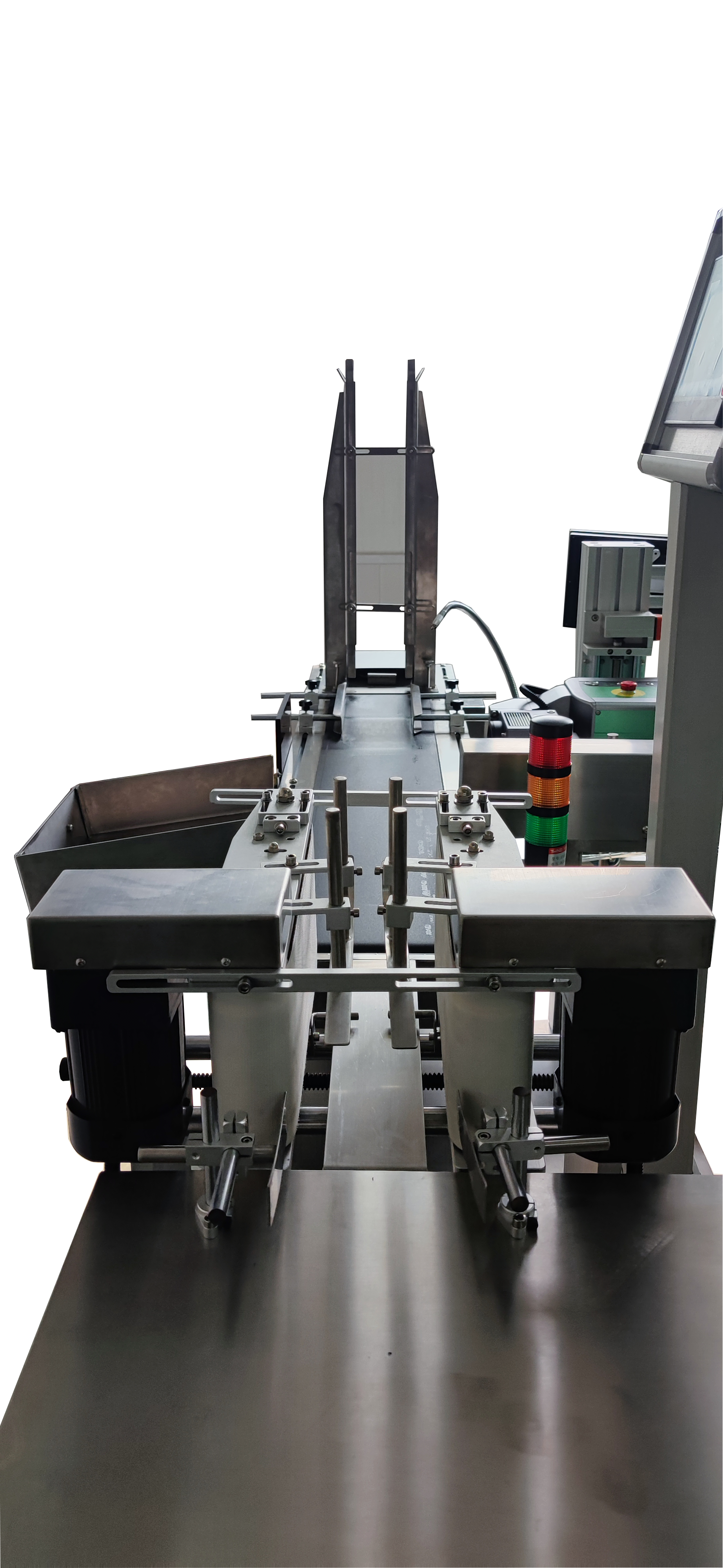

Full container acquisition correlation system

This product is applicable to many industries, suc···

Product number:FCACS-01

- Product description

- Technical parameter

- Application field

- Sample display

This product is applicable to many industries, such as automatic box erecting mechanism, automatic code spraying of laser machine (the coding equipment can be customized according to the demand), automatic collection of box code by collector, PC related data, collection of box code, related out of warehouse management software, code scanning, out of warehouse and check the whereabouts!

Technical parameters of equipment

parameter | index | parameter | index |

Laser wavelength | 1064nm | humidity | Relative humidity 95% RH, non condensing |

Average output power | 30W | operating system | windows |

Beam quality | ㎡<1 | Operating language | English |

Modulation frequency | 20KHZ-80KHZ | typeface | Support all TTF fonts, laser marking special fonts |

Carving depth | 0.01mm-0.3mm(Depending on the actual product) | Maximum linear writing speed | 13000mm/s |

Minimum line width | 0.01mm | Cooling system | Air cooling |

Minimum character | 0.1mm | power supply | single-phase,220VAC,1KVA |

Repeatability | ±0.03 | Marking range | 200mmX200mm(Optional) |

Power consumption of the whole machine | 500W | Interface | USB,RS232 |

ambient temperature | 5-55℃ |

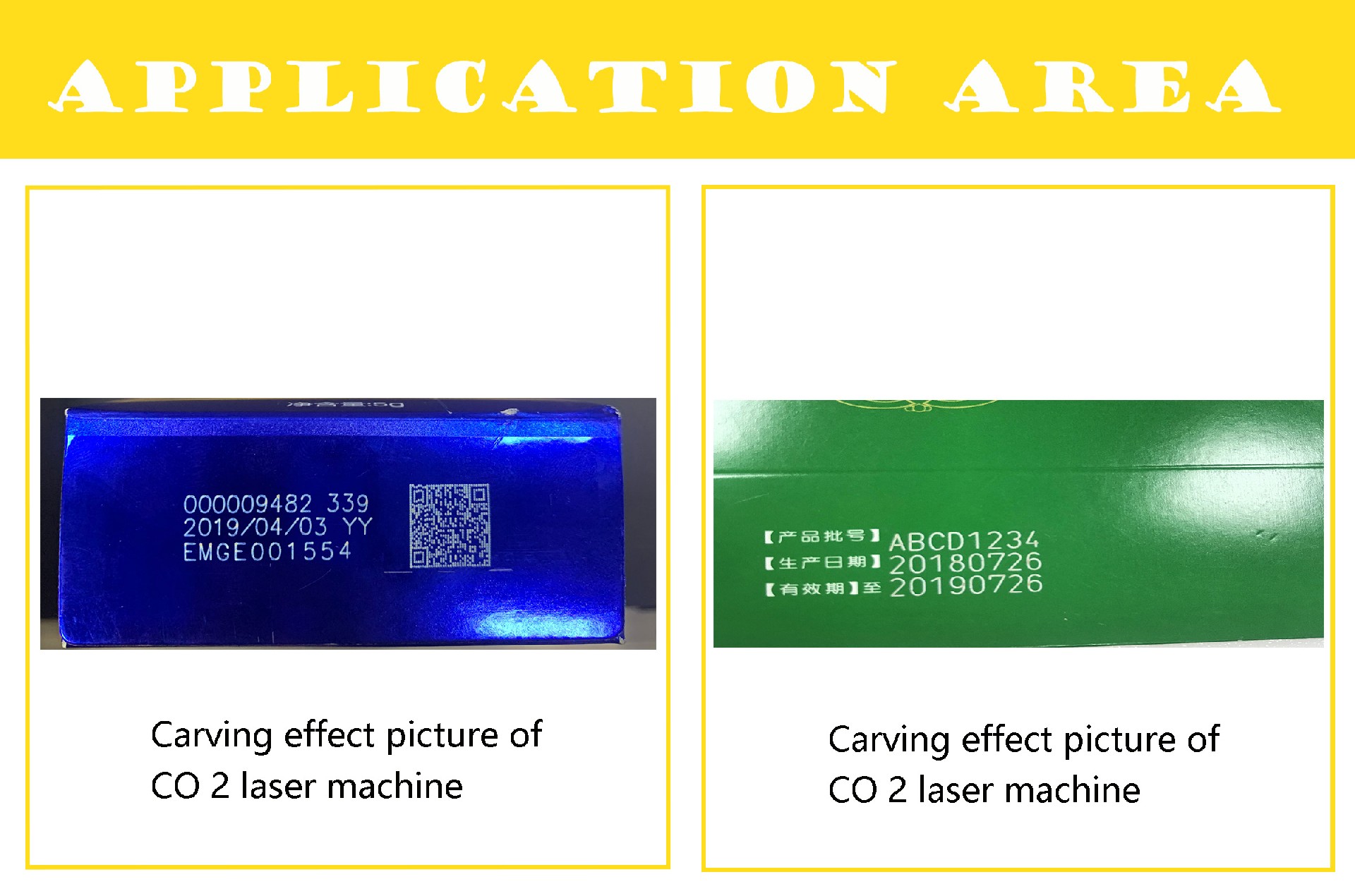

Application fields of laser machine and visual inspection

Application of appearance defect detection

This link is also the link that replaces the most labor to detect whether the products on the production line have quality problems. For example, in the field of medicine involved in machine vision, its main detection includes size detection, bottle body appearance defect detection, bottle shoulder defect detection, bottle mouth detection, etc. With the development of modern industrial automation, machine vision detection is widely used in a variety of inspection, measurement and part recognition, such as surface defect detection of new energy power batteries, electronic component recognition, appearance defect detection of magnetic materials, bar code and character recognition on product packaging, etc. the common feature of such applications is continuous mass production The requirements for appearance quality are very high. With the improvement of economic level, machine vision detection has attracted more and more attention. It can improve the production capacity of qualified products and scrap inferior products in the early stage of the production process, so as to reduce waste and save cost.

Laser marking machine is used in IT industry, communication industry, machine manufacturing industry, food and medicine, medical equipment, watch glasses, craft gifts, precious metal jewelry, leather clothing, packaging and printing stove, precision hardware, jewelry, electrical appliances, instruments and other metal processing industries

ENQUIRYFull container acquisition correlation system

Chinese

Chinese English

English